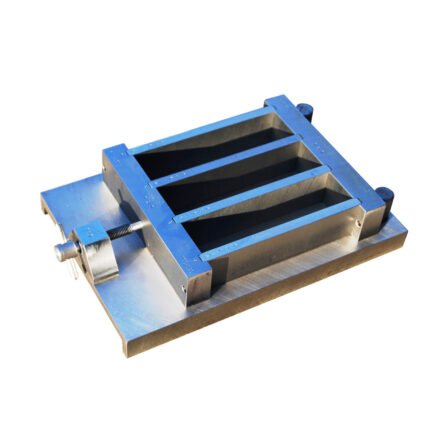

AZA 0797 SHRINKAGE BAR MOULD

IS 4031, 10086, ASTM C 227. & BS 1881.

The mould is used for casting specimens of cement & aggregate combinations for measuring the potential expansive alkali reactivity. Size of the mould is 25 x 25 x 282 mm and effective size is 25 x 25x 250 mm.

Available Models:

AZA 0797-A – Shrinkage Bar Mould – One Gang (One Compartment)

AZA 0797-B Shrinkage Bar Mould-Two Gang (Two Compartment)

AZA 0797-C Shrinkage Bar Mould – Three Gang (Three Compartment)

AZA 0797-D Shrinkage Bar Mould – Four Gang (Four Compartment)

Related products

AZA 0786 CEMENT SAMPLER

AZA 0788 VICAT NEEDLE APPARATUS WITH DASHPOT

AZA 0799 VOLUME CHANGE APPARATUS

AZA 0802 DIGITAL BLAINE AIR PERMEABILITY APPARATUS

AZA 0803 TENSILE STRENGTH TESTER (ELECTRICALLY OPERATED)

AZA 0808 PRISM MOULD THREE GANG

AZA 0810 FULLY AUTOMATIC MORTAR MIXER

EN 196-1, 196-3, 413-2, 459-2, 480-1, 1015-2, 12617-4; ASTM C187, C305; AASHTO T129, T131, T162

The mixer has been designed to mix mortars and cement pastes primarily to the requirements of standards. The mixing paddle has a planetary motion and is driven by a motor with a microprocessor-based speed and preset programs to meet all listed EN and ASTM standards, custom designed programs or manual mode. The mode button is used for the fast selection of different programs. The mixing paddle revolves at a rate of 140 rpm. with a planetary motion of 62 rpm. in low speed. In high speed, the paddle revolves at the rate of 285 rpm. with a planetary motion of 125 rpm. An automatic sand dispenser is supplied with the machine and the sand is automatically discharged. Custom design allows 6 programs to be set by the operator, where the motor speed, sand dispenser position and duration of the mix can be set. For the mix where the motor speed is selected as zero, the bowl can be lowered without interrupting the rest of the program. On the display the user can see the mix time and the machine is equipped with lamp in order to warn the user for critical time periods.

The Automatic Programmable Mortar Mixer is supplied complete with:

Bowl: 5 lt (approx.) Beater

Dimensions: 300 x 555 x 610 mm

Weight (approx.): 56 kg Power: 200 W

AZA 0811 VIBRATING MACHINE

IS4031 1968, IS1344 1959, BS 4550. Concrete moulds are easily cast by using a tamping bar or a vibrating table. However air trapped in cement mortar paste cannot be thus removed while casting cement mortar moulds. Easy method is to impart greater vibrating of lesser amplitude to the mould while casting This is achieved in a vibrating machine. Vibrating machine is used for the preparing of mortar cubes for the determination of compression strength of ordinary and rapid hardened Portland cement, low heat Portland cement, Portland blast furnace cement and high alumina cements.

Specification:

The machine consists of a vibrating frame assembly and an electric motor mounted on a sturdy base. The complete frame assembly consists of a vice to hold a 70.6 mm cube mould and two studs threaded at top and a hopper to feed the sample in the mould. This assembly is supported on four springs and has an in built rotating shaft which rotates eccentrically and thus imparts vibrations to the entire frame. A balance weight is an integral bottom part of the frame. The center of gravity of the assembly is brought to the centre of the eccentric shaft within a distance of 25 mm below it. The electric motor drives the shaft of the frame and thus imparts required vibration to the moulds.

The frequency of vibration is 12000 +/- 400 Vibration Per Minute. Supplied complete with on 70.6 mm Cube Mould with loose base plate, a time switch 0-5mins x 1mm.

Spares: Set of springs, belt and belt guard. Optional: Digital Preset Timer can be supplied at an extra cost.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items