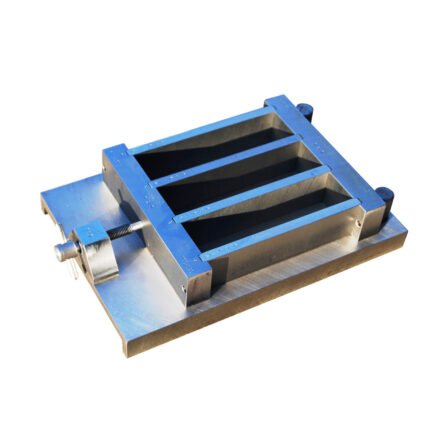

AZA 0807 JOLTING APPARATUS

- Standard-compliant jolting apparatus for cement mortar

- Ideal for compacting 40x40x160 mm prism specimens

- Delivers 60 jolts per minute for uniform compaction

- Automatic timer, safety shield & heavy-duty motor

- Used in cement labs, R&D, and educational institutions

- Meets IS 10080, ASTM, and EN testing requirements

Description

The AZA 0807 Jolting Apparatus is a specialized laboratory instrument designed to compact cement mortar specimens uniformly and reproducibly. This ensures that test specimens prepared for compressive and flexural strength testing are free from air voids and maintain consistent density across batches. Conforming to IS 10080:1982, the equipment is a vital asset in any cement testing facility, enabling high-standard testing procedures as required by BIS, ASTM, and EN standards.

Whether you’re a construction company lab, an educational institute, a quality control division, or a research lab in cement product development, the AZA 0807 provides precise performance and rugged reliability.

🔗 Also recommended: AZA 0806 Prism Mould – 40x40x160mm

⚙️ Why Compaction Matters in Mortar Testing

Cement mortar’s performance characteristics—like compressive strength, flexural strength, and shrinkage—depend heavily on the homogeneity and compaction of the test specimen. Improperly compacted samples can introduce air gaps and inconsistencies that compromise test reliability.

The AZA 0807 uses a mechanically driven cam system to apply 60 controlled jolts per minute to the sample mould, helping eliminate internal air pockets. A precise timer system ensures the test ends after the correct number of jolts, typically 60 jolts in 60 seconds.

🛠 Use Cases Across Industries

-

✔️ Cement manufacturing plants for routine quality assurance

-

✔️ Civil engineering and construction research labs

-

✔️ Educational institutions conducting standardized mortar tests

-

✔️ Building material certification centers

-

✔️ R&D facilities developing specialty cement products

🌟 Key Features & Benefits

-

✅ Standard Compliance – Meets IS 10080, EN 196-1, and ASTM C348 for mortar compaction

-

✅ Consistent Jolting Action – 60 jolts/min with calibrated camshaft movement

-

✅ Heavy-Duty Steel Frame – Vibration-resistant, long operational life

-

✅ Automatic Timer – Stops jolting after pre-set duration to eliminate overcompaction

-

✅ Safety Guard – Covers moving components to avoid accidents during operation

-

✅ Easy Clamping System – Firmly holds prism moulds in place

-

✅ Compact Bench-Top Design – Saves space without compromising performance

-

✅ Low Maintenance – Enclosed mechanism requires minimal lubrication

🔗 External References (rel=”nofollow”)

-

<a href=”https://www.services.bis.gov.in:8071/tmp/BIS/std/IS10080.pdf” target=”_blank” rel=”nofollow”>IS 10080: Jolting Apparatus Standard (BIS)</a>

-

<a href=”https://www.astm.org/c0348-20.html” target=”_blank” rel=”nofollow”>ASTM C348 – Flexural Strength of Mortars</a>

-

<a href=”https://www.cement.org/” target=”_blank” rel=”nofollow”>Portland Cement Association – Cement Testing Resources</a>

-

<a href=”https://nptel.ac.in/courses/105102012″ target=”_blank” rel=”nofollow”>NPTEL: Testing of Cement & Mortar (IIT Bombay)</a>

Specifications

| Specification | Details |

|---|---|

| Model | AZA 0807 |

| Application | Mortar Prism Compaction |

| Conformity | IS 10080, EN 196-1, ASTM C348 |

| Jolts/Min | 60 jolts per minute (adjustable on request) |

| Timer | 60 sec automatic timer |

| Compatible Mould Size | 40x40x160 mm |

| Motor Power | 0.25 HP, 230 V AC |

| Construction | Mild Steel Frame, Powder Coated |

| Dimensions (LxWxH) | Approx. 500 × 350 × 450 mm |

| Weight | Approx. 35–40 kg |

| Warranty | 1 Year (against manufacturing defects) |

| Made In | India |

❓ Frequently Asked Questions (FAQs)

Q1: What is the function of a jolting apparatus?

A: It compacts cement mortar in prism moulds through jolting, ensuring no air voids or segregation, and preparing consistent samples for strength testing.

Q2: How many jolts does the AZA 0807 deliver?

A: It typically delivers 60 jolts in one minute, as per IS 10080 standard. Custom settings are available based on user need.

Q3: Can it be used with any mould?

A: It is compatible with standard 40 mm x 40 mm x 160 mm prism moulds with proper clamping system.

Q4: Is it suitable for student use?

A: Yes. With built-in safety features and timer controls, it is suitable for educational labs, provided under supervision.

Q5: Is maintenance difficult?

A: Not at all. The apparatus features grease-free cams, sealed housings, and is easy to clean after use.

Additional information

| Model |

AZA 0807 |

|---|---|

| Application |

Mortar Prism Compaction |

| Conformity |

IS 10080, EN 196-1, ASTM C348 |

| Jolts/Min |

60 jolts per minute (adjustable on request) |

| Dimensions (LxWxH) |

Approx. 500 × 350 × 450 mm |

| Weight |

Approx. 35–40 kg |

| Warranty |

1 Year (against manufacturing defects) |

| Made In |

India |

Related products

AZA 0789 RING MOULD

AZA 0790 GILLMORE NEEDLE APPARATUS

AZA 0799 VOLUME CHANGE APPARATUS

- Precision apparatus for measuring soil volume change

- Ideal for CD and CU triaxial testing

- Manual and digital versions available

- Durable lab-grade stainless steel build

- Fully compliant with IS and ASTM standards

- Provided with all necessary accessories

- Backed by Azalab’s quality assurance and support

AZA 0808 PRISM MOULD THREE GANG

- Triple-cavity unit for mortar sample casting

- Ideal for compressive/flexural testing

- IS/EN-compliant precision mould

- Lab-grade cast iron build

- Smooth de-moulding and cleaning

AZA 0811 VIBRATING MACHINE

- Powerful vibrating machine for concrete specimen compaction

- Adjustable vibration frequency and amplitude

- Suitable for cubes, cylinders, and beams

- Conforms to IS 516 and ASTM C192 standards

- Durable steel construction with corrosion resistance

- Compact design and user-friendly operation

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items