KINEMATIC VISCOMETER BATH AZA0948

The AZA0948 Kinematic Viscometer Bath from AZALAB is a precision-controlled laboratory bath designed to provide a stable and uniform temperature environment for determining the kinematic viscosity of liquids using calibrated glass capillary viscometers. Accurate viscosity measurement is critical for quality control and specification compliance in bitumen, asphalt, petroleum products, lubricants, and industrial fluids.

Kinematic viscosity, expressed in centistokes (cSt) or mm²/s, is highly sensitive to temperature variations. The AZA0948 addresses this requirement through precise PID-based temperature control, uniform circulation, and high-visibility construction, ensuring repeatable and standards-compliant test results.

Description

Purpose & Function

The AZA0948 maintains a constant and uniform bath temperature during viscosity testing as required by international standards. Glass capillary viscometers containing the test sample are immersed in the bath until thermal equilibrium is achieved. The efflux time of the liquid under gravity is measured and multiplied by the viscometer constant to determine kinematic viscosity.

Standards Compliance

- ASTM D445 – Kinematic viscosity of transparent and opaque liquids

- IS 1206 (Part 3) – Kinematic viscosity of bituminous materials

- ISO 3104

- IP 71

Widely accepted for VG Bitumen grading as per IS 73 and MoRTH specifications.

Key Features

- High-Precision Temperature Control: Microprocessor-based PID controller ensures temperature stability of ±0.1°C or better

- Uniform Temperature Distribution: Motorized stirrer / circulation system eliminates thermal gradients

- Double-Walled Construction: SS inner tank with insulated outer cabinet for thermal efficiency

- High Visibility: Toughened glass windows on two sides for clear observation of viscometers

- Multi-Viscometer Capacity: Supports simultaneous testing of multiple capillary viscometers

- Chemical Resistance: Stainless steel inner tank resists corrosion from oils and bituminous materials

- Laboratory-Grade Build: Designed for continuous use in QC and R&D laboratories

Applications

- Bitumen and asphalt binder testing (VG grading, cut-back bitumen)

- Petroleum products and lubricating oils

- Fuel and hydraulic oil quality control

- Industrial fluid characterization

- Research, academic, and material development laboratories

Technical Specifications

| Parameter | Description |

|---|---|

| Model | AZA0948 |

| Test Method | Kinematic viscosity using glass capillary viscometers |

| Temperature Range | Ambient +5°C to 100°C / 120°C (higher ranges up to 150–200°C optional) |

| Temperature Stability | ±0.1°C or better |

| Controller | PID digital temperature controller |

| Display Resolution | 0.1°C |

| Stirring | Motorized stirrer / circulation system |

| Inner Tank | Stainless Steel (SS 304) |

| Outer Cabinet | Powder-coated GI / mild steel |

| Insulation | Glass wool / PUF insulation |

| Viewing Windows | Toughened glass (two sides) |

| Viscometer Capacity | 2, 4, 6 or 8 viscometers (model dependent) |

| Power Supply | 230 V AC, 50 Hz, Single Phase |

Supplied Accessories

- Universal viscometer holders

- Suction bulb

- Drain valve (model dependent)

Optional Accessories

- Glass capillary viscometers (Cannon-Fenske, Ubbelohde, etc.)

- Calibrated ASTM thermometers

- Digital stopwatch

- Viscosity reference oils

- Cooling coil for below-ambient operation

- High-temperature oil bath configuration

Frequently Asked Questions (FAQ)

Q1: What is the primary use of the AZA0948?

It provides a stable temperature bath for kinematic viscosity testing using glass capillary viscometers.

Q2: Why is precise temperature control essential?

Viscosity varies significantly with temperature. Even small fluctuations can lead to inaccurate results.

Q3: Is it suitable for bitumen viscosity testing?

Yes. It fully supports IS 1206 (Part 3) and ASTM D445, commonly used for VG bitumen testing.

Q4: Are viscometers included?

Viscometers are typically supplied separately, as selection depends on viscosity range.

Q5: Can multiple samples be tested simultaneously?

Yes. The bath is designed to hold multiple viscometers depending on the selected capacity.

Summary of Advantages

- Accurate and stable temperature control for viscosity testing

- High visibility and ease of operation

- Supports multiple international standards

- Suitable for bitumen, petroleum, and industrial fluids

- Robust AZALAB build quality for long-term laboratory use

AZA0948 – Precision Temperature Control for Reliable Kinematic Viscosity Measurement

Additional information

| Model Number |

AZA 0948 |

|---|---|

| Resolution |

$0.1^\\circ\\text{C}$. |

| Inner Tank Material |

Stainless Steel (SS 304 grade). |

| Outer Cabinet Material |

Powder Coated GI (Galvanized Iron) sheet. |

| Insulation |

High-density glass wool or PUF. |

Related products

AUTOMATIC MARSHALL STABILITY TEST MACHINE AZA0954

The AZA0954 Automatic Marshall Stability Test Machine from AZALAB is a cornerstone instrument for modern civil engineering, highway material, and asphalt testing laboratories. Designed for fully automated determination of Marshall Stability and Marshall Flow, the AZA0954 plays a critical role in asphalt mix design, quality control, and performance evaluation of bituminous pavements.

Compared to conventional manual Marshall testers, the AZA0954 represents a significant technological advancement, offering superior accuracy, repeatability, operational efficiency, and digital data management. It is ideally suited for laboratories handling high sample volumes, regulatory testing, and advanced pavement research.

FILTERLESS CENTIFUGE EXTRACTOR AZA0947

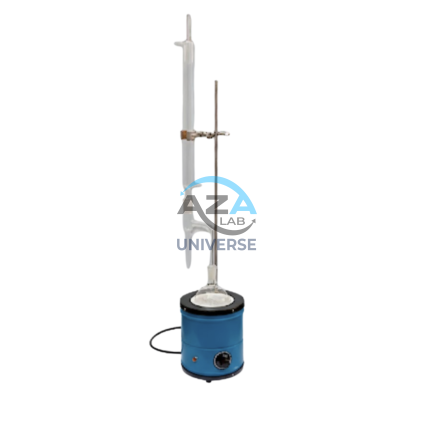

REFLUX EXTRACTOR 4000 GMS AZA0941

The AZA0941 Reflux Extractor 4000 GMS from Azalab is a high-efficiency laboratory apparatus designed for the quantitative determination of bitumen content in asphalt paving mixtures using the reflux extraction method. Engineered for large sample capacities up to 4000 grams, the AZA0941 is an essential instrument for civil engineering laboratories, road construction quality control, and materials testing facilities.

By ensuring accurate separation of bitumen binder from aggregates, the AZA0941 helps verify compliance with asphalt mix design specifications, directly contributing to durable, high-performance pavement construction.

RING & BALL APPARATUS(SEMI AUTOMATIC) AZA0934

The AZA0934 Ring & Ball Apparatus (Semi-Automatic) from Azalab is an advanced laboratory instrument designed for the precise determination of the softening point of bitumen, asphalt binders, and related bituminous materials. This critical test evaluates the temperature susceptibility and high-temperature performance of asphalt binders, directly influencing pavement resistance to rutting and permanent deformation under hot service conditions.

By integrating the standard Ring & Ball method with semi-automatic control and detection features, the AZA0934 significantly improves accuracy, repeatability, and operational efficiency, making it ideal for modern quality control, research, and specification laboratories.

SAY BOLT VISCOMETER AZA0950

The AZA0950 Saybolt Viscometer from AZALAB is a fundamental laboratory instrument designed to determine the empirical viscosity of petroleum products, lubricants, and bituminous materials. Viscosity—defined as a fluid’s resistance to flow—is a critical performance parameter influencing lubrication efficiency, fuel handling, and asphalt workability.

The Saybolt method measures efflux time, providing a standardized and widely accepted indication of flow behavior at controlled temperatures.

SEMI-AUTOMATIC PENETROMETER AZA0940

The AZA0940 Semi-Automatic Penetrometer from Azalab is a high-precision laboratory instrument designed for the accurate determination of the consistency of bituminous materials, including bitumen, asphalt, and other semi-solid products such as greases and waxes. Engineered to bridge the gap between manual and fully digital systems, the AZA0940 combines robust mechanical construction with digital timing and automated needle release, delivering excellent accuracy, repeatability, and ease of operation.

This instrument is widely used in civil engineering laboratories, highway authorities, asphalt plants, research institutions, and quality control laboratories, where dependable penetration testing in compliance with ASTM D5, EN 1426, and AASHTO T49 is required.

STANDARD PENETROMETER AZA0938

The AZA0938 Standard Penetrometer from Azalab is a robust, reliable, and manually operated laboratory instrument designed for the accurate determination of the consistency of bituminous materials, including bitumen, asphalt, waxes, and greases. It is an essential testing device widely used in civil engineering laboratories, highway authorities, asphalt plants, and quality control laboratories where consistent and repeatable penetration measurements are required.

The AZA0938 operates on the classical penetration testing principle and provides a cost-effective yet precise solution for grading and classifying bituminous binders in accordance with internationally recognized standards such as ASTM D5, EN 1426, AASHTO T49, IP 49, and IS 1203.

WATER IN BITUMINOUS MATERIAL (DEAN-STARK) AZA0936

The AZA0936 Water in Bituminous Material (Dean–Stark) Apparatus from Azalab is a precision laboratory system designed for the accurate determination of water content in bituminous materials, including asphalt, road oils, cut-back asphalts, and related petroleum-based binders.

Water contamination in bitumen can significantly degrade material performance by causing poor adhesion to aggregates, stripping, foaming during mixing, and reduced pavement durability. Using the internationally accepted Dean–Stark azeotropic distillation method, the AZA0936 provides reliable, repeatable, and standard-compliant moisture determination, making it essential for quality control in road construction, civil engineering laboratories, and bitumen production facilities.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items