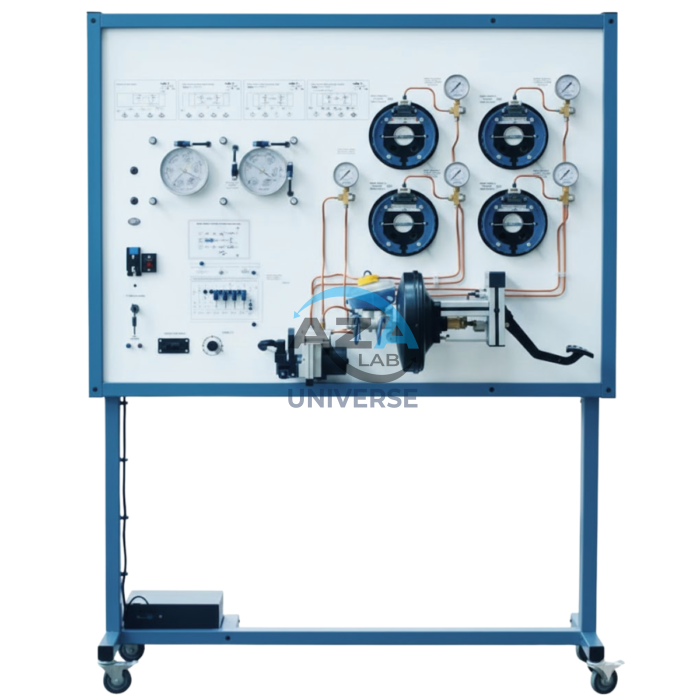

ABS Braking System Training Board Simulator AZA1245

The AZA1245 AZALAB ABS Braking System Training Board Simulator is a fully functional automotive training platform designed to provide in-depth, hands-on understanding of Anti-lock Braking System (ABS) operation, diagnostics, and repair procedures. Built using real automobile components, this simulator enables students and technicians to study ABS structure, electronic control, hydraulic behavior, and fault diagnostics in a safe and controlled learning environment.

This training system is ideal for automotive training institutes, engineering colleges, technical schools, and service technician programs, supporting both instructional demonstrations and practical troubleshooting exercises.

Description

Modern automotive braking systems rely heavily on electronic control and sensor-based feedback to ensure safety and stability. The AZA1245 accurately replicates a working ABS braking system, allowing learners to observe and interact with real-time braking behavior, hydraulic pressure variation, and ECU-controlled modulation.

Mounted on a robust, mobile aluminum frame, the training board provides full visibility of all major ABS components, making it suitable for classroom demonstrations as well as hands-on service training.

System Design & Construction

The simulator is constructed using original automotive ABS components, arranged for maximum clarity and accessibility:

- Cross-diagonal hydraulic braking system

- Front and rear brake assemblies (with brake drums used for improved pressure visualization)

- Electronic ABS control unit (ECU)

- Functional brake booster

- Pressure gauges for monitoring brake circuit pressure

- Functional parking brake

All components are clearly exposed and labeled, allowing students to easily identify system parts and understand their interaction during braking events.

Functional Capabilities

The AZA1245 allows users to perform a wide range of practical learning activities:

- Demonstration of normal and ABS-assisted braking operation

- Observation of hydraulic pressure changes during braking

- Simulation of driving conditions for dynamic ABS operation

- Measurement and testing of electrical signals using built-in test points

- Mechanical service and repair training

The simulator supports driving mode simulation, enabling dynamic demonstrations of ABS modulation under braking scenarios.

Diagnostics & Fault Simulation

To support modern automotive diagnostics training, the system includes:

- OBD 16-pin diagnostic connector

- ECU identification

- Fault code reading and erasing

- Live data display

- Actuator activation via control unit

An integrated electric wiring diagram with banana plug jumpers allows instructors to introduce faults intentionally. Students can then perform measurements, diagnose issues, and restore correct system operation, closely simulating real workshop conditions.

Educational Value

The AZA1245 is designed to bridge the gap between theory and real-world automotive service:

- Enables clear visualization of ABS operation

- Supports both electronic and hydraulic diagnostics training

- Allows repeated fault insertion and troubleshooting exercises

- Enhances student understanding of safety-critical automotive systems

It is equally effective for introductory automotive education and advanced technician skill development.

Typical Applications

- Automotive engineering and diploma programs

- Vehicle service technician training

- ABS system diagnostics and troubleshooting courses

- Demonstration of braking safety systems

- Practical workshops on electronic braking control

Key Features

- Fully functional ABS braking system trainer

- Built using original automobile components

- Cross-diagonal hydraulic braking layout

- Visible pressure gauges for brake circuit monitoring

- Functional parking brake and brake booster

- Electric wiring diagram with banana plug fault simulation

- OBD-based diagnostics with live data and fault management

- Mobile aluminum frame for easy movement

- Suitable for service, diagnostics, and repair training

Technical Specifications

| Component | Specification |

|---|---|

| Model | AZA1245 |

| ABS Braking System | Fully functional with pressure gauges |

| Hydraulic Brake System | Original system (brake drums used for pressure visualization) |

| Power Supply | 12V battery or 220V / 12V power supply unit |

| Diagnostic Support | Automotive oscilloscope, OBD diagnostic scan tool |

| OBD Interface | 16-pin connector |

| Dimensions (L×W×H) | 1360 × 550 × 1800 mm |

| Weight | 60 kg |

Product Highlights

- Realistic ABS braking system training platform

- Hands-on diagnostics with OBD connectivity

- Safe and repeatable fault simulation

- Clear visualization of hydraulic and electronic braking behavior

- Ideal for automotive education and professional training

Model: AZA1245

Related products

Alternator Trainer AZA1247

The AZA1247 AZALAB Alternator Trainer is a hands-on automotive electrical training system designed to demonstrate the working principles, construction, and diagnostics of an automotive alternator with external voltage regulation. Built using OEM automotive components, this trainer provides a realistic and safe learning platform for students, technicians, and trainees to understand vehicle charging systems in depth.

This system is ideal for automotive engineering institutes, ITIs, polytechnics, vocational training centers, and service technician programs, supporting both theoretical instruction and practical experimentation.

Car Steering Trainer AZA1248

The AZA1248 Car Steering & Suspension System Trainer is an advanced automotive training platform designed to provide complete practical understanding of modern vehicle steering and front suspension systems. Developed using real automotive components and mounted on a robust mobile steel structure, this trainer enables students and technicians to gain hands-on experience in inspection, diagnosis, adjustment, and repair of steering and suspension assemblies commonly used in passenger vehicles.

This training system accurately represents a front-wheel steering and suspension layout, incorporating MacPherson strut suspension, coil spring, road wheels, hub carrier assemblies, and a fully operational power steering system. The open-frame design allows clear visibility of all components, making it ideal for instructor-led demonstrations as well as individual hands-on practice in automotive laboratories and technical institutes.

Cut Model of Agricultural Tractor AZA1254

The AZA1254 Cut Model of Agricultural Tractor by AZALAB is a highly detailed and precision-engineered educational training model designed to provide a clear, practical understanding of agricultural tractor construction, internal mechanisms, and working principles. This cutaway model is specifically developed for engineering colleges, ITIs, polytechnic institutes, agricultural universities, and vocational training centers.

Manufactured using an actual agricultural tractor assembly, the AZA1254 is carefully sectioned to expose all major mechanical and functional systems. Each component is accurately cut, polished, and color-coded, enabling learners to visually trace power flow, understand system interconnections, and study component functions in real time. The model offers an authentic representation of tractor operation, making it ideal for classroom demonstrations, lab training, and technical instruction

Cut Model of Automatic Transmission System AZA1249

The AZA1249 Cut Model of Automatic Transmission System by AZALAB is a precision-engineered educational trainer designed to demonstrate the construction, operation, and working principles of a hydraulic automatic transmission system used in modern passenger vehicles. Developed using a full-size original car automatic transmission, this cutaway model provides an authentic, hands-on learning experience for automotive students and technicians.

The transmission assembly is carefully sectioned and color-coded to expose all major internal components, allowing clear visualization of power flow, gear shifting logic, and hydraulic control mechanisms. Mounted on a sturdy tubular steel frame with wheels, the AZA1249 is easy to move within classrooms, laboratories, and workshops, making it ideal for group demonstrations and instructor-led training.

Cut Model of Self-Starting System AZA1251

The AZA1251 Cut Model of Self-Starting System by AZALAB is a fully functional automotive training model designed to demonstrate the construction, operation, and diagnostics of a vehicle starting system. Developed using real automotive starter components, this cutaway trainer provides a clear and practical understanding of how electrical energy from a battery is converted into mechanical motion to crank an internal combustion engine.

Specifically designed for automotive training institutes, ITIs, polytechnics, engineering colleges, and skill development centers, the AZA1251 enables students to observe live starter operation while safely viewing internal mechanisms through a transparent enclosure.

Cut Section Model of Four Stroke Petrol Engine AZA1253

The AZA1253 Cut Section Model of Four Stroke Petrol Engine by AZALAB is a precision-engineered educational training model designed to provide a clear and practical understanding of four-stroke petrol engine construction and operation. Developed specifically for engineering colleges, ITIs, polytechnics, vocational training centers, and automotive laboratories, this model presents a detailed sectional view of an actual four-stroke petrol engine.

The cutaway design exposes all major internal components, allowing students to visually study how mechanical and thermodynamic processes occur inside the engine during each stroke—intake, compression, power, and exhaust.

LAB Cut Model of Planetary Gear System AZA1250

The AZA LAB Cut Model of Planetary Gear System – Model AZA1250 is a practical and educational training aid designed to demonstrate the working principles of a planetary gear mechanism in a clear and visual manner. This fully functional, hand-powered cutaway model allows students and trainees to observe torque transmission and power distribution within a planetary gear system.

Widely used in automatic automobile transmissions, ship propulsion systems, turbines, and industrial gearboxes, planetary gear systems can be complex to understand through theory alone. The AZA1250 model bridges this gap by offering full visibility of internal components, making it an essential teaching tool for engineering classrooms, workshops, and vocational training institutes.

LAB Cut Model of Turbocharger AZA1252

The AZA LAB Cut Model of Turbocharger – Model AZA1252 is a detailed educational cutaway designed to clearly demonstrate the working principles of a turbocharger used in modern automotive engines. This model provides an in-depth visual understanding of forced induction systems, showing how exhaust gases drive a turbine to compress intake air and increase engine power and efficiency.

Purpose-built for engineering education and technical training, the AZA1252 exposes all critical internal components, allowing students to study airflow, exhaust flow, and cooling pathways in a realistic and intuitive manner.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items