Abrasion Testing Machine for Glazed Tiles (AZA 1262)

Reliable Abrasion Testing Machine for Glazed Tiles, compliant with BIS 13630-11 and EN ISO 10545-7, designed for precise, high-speed abrasion testing of up to 4 specimens.

Description

The Abrasion Testing Machine for Glazed Tiles is designed to evaluate the abrasion resistance of glazed ceramic tiles, fully compliant with BIS 13630-11 and EN ISO 10545-7 standards. This machine offers precise and reliable testing for durability and wear resistance, ensuring glazed tiles maintain their visual and functional integrity over time.

Featuring a 580 mm rotating disc with an eccentricity of 22.5 mm, the machine simulates real-world wear by applying consistent pressure. The motor operates at a speed of 300 ± 10 rpm, powered by a 1/4 HP single-phase 230V AC supply. The machine can test up to 4 specimens at a time, with a specimen holding ring that has an inside diameter of 83 mm. The distance from the center of the disc to the test area is 195 mm. The 4-digit preset electronic counter with memory backup and key-lock reset ensures accurate and repeatable testing cycles, making it a vital tool for high-precision tile testing.

With overall dimensions of 1100 x 760 x 630 mm and a weight of approximately 177 kg, this robust machine is built to withstand the demands of a high-traffic testing environment.

- Standards Compliance: Meets BIS 13630-11 and EN ISO 10545-7 for glazed tile abrasion resistance testing.

- Large Rotating Disc: 580 mm diameter disc with 22.5 mm eccentricity for realistic wear simulation.

- High-Speed Operation: 1/4 HP, single-phase 230V AC motor running at 300 ± 10 rpm.

- Multiple Specimen Testing: Tests up to 4 specimens at once, providing efficient and consistent results.

- Secure Specimen Holding: 83 mm inside diameter specimen holding ring ensures stable placement during testing.

- Precise Digital Control: 4-digit preset electronic counter with memory backup and key-lock reset for accurate and repeatable cycles.

- Compact Dimensions: Overall size of 1100 x 760 x 630 mm, designed for easy integration into testing labs.

- Diameter of Rotating Disc: 580 mm

- Eccentricity of Axis of Rotation: 22.5 mm

- Speed of Rotation of Disc: 300 ± 10 rpm

- Max. Number of Test Specimens Tested at a Time: 4

- Inside Diameter of Specimen Holding Ring: 83 mm

- Distance of Test Area from Center of Disc: 195 mm

- Electric Motor Power: 1/4 HP, Single-phase, 230V, 50 Hz AC supply

- Digital Counter: 4-digit preset type electronic counter with memory backup and key-lock reset

- Overall Dimensions (L x W x D): 1100 x 760 x 630 mm

- Weight (Approx.): 177 kg

Related products

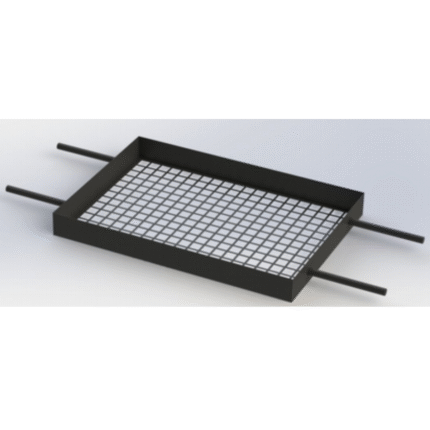

BALLAST SIEVE – 100 x 70 x 10 cm – 65 mm ( AZA -1299)

The AZA LAB Ballast Sieve Series is designed for the efficient separation, classification, and inspection of railway ballast and coarse aggregates. These sieves are fabricated using heavy-duty steel frames and precision-cut mesh, suitable for demanding environments in both field and laboratory settings.

Each sieve is dimensionally standardized at 100 x 70 x 10 cm, with a custom mesh opening specific to grading needs: 65mm, 40mm, 20mm, and 41.50mm.

These units are ideal for use by railway contractors, quality control labs, construction material testing authorities, and civil engineering departments.

Applications:

- Railway ballast size grading

- Aggregate separation for construction quality control

- Material classification in civil engineering labs

- On-site ballast inspection by railway authorities

DEEP ABRASION MACHINE FOR UNGLAZED TILES (AZA 1260)

FLUX OVEN – 50 KG – STAINLESS STEEL (AZA -1273)

The AZA LAB Flux Oven (50 kg capacity) is a high-performance drying oven designed for precise and uniform heating of flux materials in laboratory and industrial environments. Built with a durable double-walled structure, the oven ensures energy efficiency and thermal stability, making it ideal for demanding applications in ceramics, metallurgy, and materials processing.

With a temperature range of 50°C to 400°C, this oven is equipped with forced air circulation, PID temperature control, and even heat distribution, guaranteeing consistent performance. Safety features include over-temperature protection with an audio alarm, and compatibility with optional data logging systems.

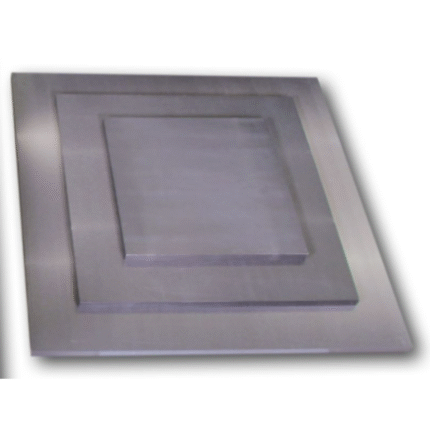

MASTER CALIBRATING PLATE / ZEROING PLATE (AZA – 1270)

AZA LAB's Master Calibrating Plate—also known as a Zeroing Plate—is a precision-engineered aluminum reference plate designed for accurate calibration of Universal Gauges and Plucometers. Manufactured in compliance with IS 13630 (Part-1) and EN ISO 10545 (Part-2) standards, it ensures reliable and repeatable zero-point reference during dimensional testing of ceramic tiles and similar materials.

The plate is available in a wide range of sizes to suit various laboratory and industrial applications. With a flatness accuracy of ±0.1 mm and a sturdy 12 mm thickness, it provides a stable and durable base for equipment calibration.

Whether in QC labs or production floors, the AZA LAB Zeroing Plate is an essential tool for maintaining measurement consistency and ensuring compliance with international tile testing standards.

ROTAP SIEVE SHAKER (AZA 1302)

The AZA LAB ROTAP Sieve Shaker is a precision-engineered mechanical device designed for accurate particle size analysis in materials such as soil, sand, cement, aggregates, and powders. Combining rotary and tapping actions, it offers consistent, repeatable performance and complies with most national and international standards for sieve testing.

With rugged construction and intuitive operation, this shaker supports a wide range of test sieves and is suitable for demanding laboratory and industrial environments.

Test Specimen Holder for Surface Abrasion Machine – For Glazed Tiles (AZA 1264)

Visual Assessment Cabinet – Viewing Cabinet – BIS 13630 (AZA 1263)

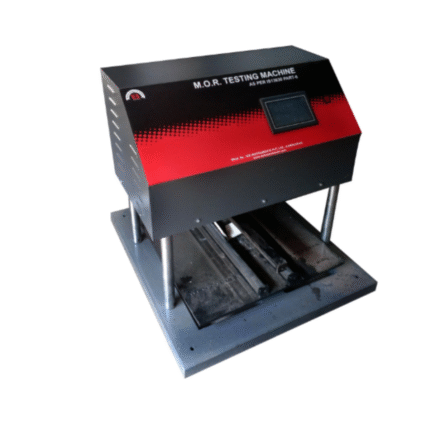

WET TRANSVERSE STRENGTH TESTING MACHINE (AZA -1268)

The Wet Transverse Strength Testing Machine is a rugged electro-mechanical system designed for quiet, vibration-free operation. It features a precision load control system driven by an integrated induction motor and drive, ensuring consistent and repeatable test results.

Suited for laboratories, R&D departments, and quality control units in cement tile manufacturing.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items

Reviews

There are no reviews yet.