AZA 0865 HEAVY COMPACTION TEST

- Heavy Compaction Test: Specifically designed to perform the Modified Proctor Compaction Test.

- High Compaction Energy: Utilizes a heavier hammer and greater drop height for higher soil density requirements.

- Crucial for Critical Projects: Essential for quality control in heavy civil engineering applications like airfields and high-stress pavements.

- Complete Apparatus: Includes a robust compaction mould, heavy rammer, and necessary accessories.

- Standard Compliant: Adheres to international standards such as ASTM D1557 and equivalent IS/BS norms.

- Azalab Quality: Durable and precise equipment for reliable geotechnical testing results.

Description

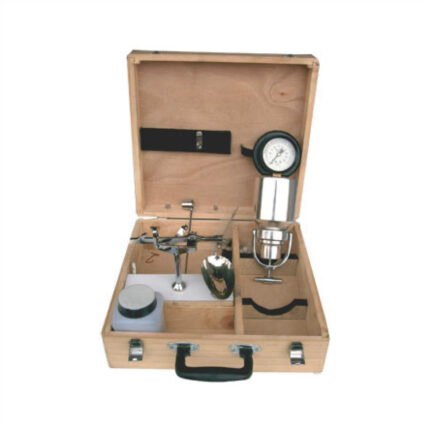

AZA 0865: Heavy Compaction Test Apparatus for Modified Proctor Analysis

The AZA 0865 Heavy Compaction Test Apparatus from Azalab is a vital piece of equipment for any geotechnical testing laboratory involved in the design and quality control of major civil engineering projects. This apparatus is specifically used to perform the Heavy Compaction Test, which is widely known as the Modified Proctor Compaction Test. This test determines the relationship between the moisture content and the dry density of a soil when subjected to a high level of compaction energy. The resulting parameters, the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC), are indispensable for ensuring the stability, strength, and durability of compacted soil layers in critical applications such as heavy-duty pavements, airfield runways, and high-embankment earth dams.

Unlike the Standard Proctor Test (which uses a lighter hammer and shorter drop height), the Heavy Compaction Test (Modified Proctor) applies significantly more compaction energy. This reflects the higher compaction efforts achievable with modern heavy construction equipment in the field. The apparatus precisely replicates these conditions in the laboratory.

The AZA 0865 Heavy Compaction Test Apparatus typically comprises:

- Compaction Mould: A cylindrical steel mould, commonly 152.4 mm (6 inches) in internal diameter and 116.4 mm (4.58 inches) in effective height (for ASTM D1557), or 150 mm (5.9 inches) diameter and 127.3 mm (5 inches) height (for IS 2720 Part VIII), with a detachable collar and a base plate. The mould volume is designed to hold a specific amount of soil for compaction.

- Heavy Compaction Rammer (Hammer): This is the core component that defines the “heavy” compaction. For ASTM D1557, it’s a 4.54 kg (10 lbs) hammer with a free fall of 457.2 mm (18 inches). For IS 2720 (Part VIII), it’s a 4.9 kg hammer with a 450 mm drop. The hammer’s face is typically 50.8 mm (2 inches) in diameter.

- Accessories: This usually includes a sample extruder (optional but highly recommended for removing compacted soil from the mould), a mixing pan, and other tools for preparing the soil sample.

Performing the Heavy Compaction Test involves compacting soil at various moisture contents in the mould in a specified number of layers (typically 5 layers for Modified Proctor), with each layer receiving a set number of blows (e.g., 25 blows for 6-inch mould) from the heavy rammer. After compaction, the compacted soil’s wet density is determined, and a sample is taken to find its actual moisture content. This process is repeated for several moisture contents, and a compaction curve is plotted to identify the MDD and OMC.

The AZA 0865 is manufactured to strict compliance with international standards, ensuring that test results are accurate, reproducible, and comparable across different laboratories and projects. Key standards include ASTM D1557 (Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort), IS 2720 (Part VIII) (Methods of test for soils: Determination of water content-dry density relation using heavy compaction), and BS 1377-4 (Methods of test for soils for engineering purposes: Compaction-related tests). Adherence to these standards is crucial for reliable geotechnical design and construction quality assurance.

Azalab’s commitment to providing high-quality geotechnical testing equipment means the AZA 0865 Heavy Compaction Test Apparatus is built from robust, durable materials, designed to withstand the repetitive impact of the compaction process in a busy laboratory setting. Investing in this apparatus ensures that your lab can accurately determine the critical compaction parameters required for high-performance earthwork and pavement layers. For further details on the significance of compaction, reference authoritative texts on “Soil Mechanics and Foundation Engineering” or relevant standards from organizations like ASTM International and the Bureau of Indian Standards (BIS).

Specifications for the AZA 0865 HEAVY COMPACTION TEST APPARATUS

- Model Number: AZA 0865

- Test Method: Heavy Compaction Test (Modified Proctor Compaction Test)

- Purpose: To determine the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC) of soils under heavy compaction effort.

- Compaction Mould (ASTM Type):

- Material: Heavy-duty steel.

- Internal Diameter: 152.4 mm (6 inches).

- Effective Height: 116.4 mm (4.58 inches).

- Volume: Approximately 2124 cm³.

- Components: Includes mould body, detachable collar, and base plate.

- Compaction Mould (IS Type – if offered as alternative/option):

- Material: Mild steel.

- Internal Diameter: 150 mm.

- Height: 127.3 mm.

- Volume: 2250 cm³.

- Components: Includes mould body, detachable collar, and base plate.

- Heavy Compaction Rammer (Hammer):

- ASTM D1557 Type: Weight 4.54 kg (10 lbs), Drop Height 457.2 mm (18 inches), Face Diameter 50.8 mm (2 inches).

- IS 2720 Part VIII Type: Weight 4.9 kg, Drop Height 450 mm, Face Diameter 50 mm.

- Note: Specific hammer type will be supplied based on chosen standard or as a set.

- Construction: Robust, heavy-duty plated or painted steel for durability and corrosion resistance.

- Included Accessories: Typically includes the mould assembly, rammer, and potentially an extruder for removing samples. Other lab essentials (balances, oven, mixing tools) are usually separate.

- Compliance: Designed to meet or exceed the requirements of:

- ASTM D1557

- IS 2720 (Part VIII)

- BS 1377-4

- Application: Geotechnical laboratories, civil engineering projects (roads, airfields, dams, foundations).

FREQUENTLY ASKED QUESTIONS (FAQ) about the AZA 0865 HEAVY COMPACTION TEST APPARATUS

Q1: What is the AZA 0865 Heavy Compaction Test Apparatus used for? A1: The AZA 0865 is used to perform the Heavy Compaction Test (also known as the Modified Proctor Compaction Test). This laboratory test determines the maximum dry density (MDD) and optimum moisture content (OMC) of soil.

Q2: How does the Heavy Compaction Test differ from the Standard Proctor Test? A2: The Heavy Compaction Test applies significantly more compaction energy than the Standard Proctor. It uses a heavier hammer (4.54 kg / 10 lbs vs. 2.5 kg / 5.5 lbs) dropped from a greater height (457.2 mm / 18 inches vs. 305 mm / 12 inches) over more layers (typically 5 layers vs. 3 layers).

Q3: Why is the Heavy Compaction Test important in civil engineering? A3: This test is crucial for projects requiring very high compaction, such as heavy-duty pavements, airfield runways, and major earth structures. It helps engineers determine the achievable density and ideal moisture for field compaction, ensuring the long-term stability and performance of these structures.

Q4: What are the main components of the AZA 0865 apparatus? A4: The primary components are the compaction mould (typically 150mm or 6-inch diameter) and the heavy compaction rammer (hammer) with its specific weight and drop height, designed as per the relevant standard (e.g., ASTM D1557).

Q5: What international standards does the AZA 0865 comply with? A5: The AZA 0865 is designed to comply with major international standards for the Modified Proctor test, including ASTM D1557, IS 2720 (Part VIII), and BS 1377-4.

Q6: What is the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC)? A6: The MDD is the highest dry density a soil can achieve under a specific compaction effort. The OMC is the moisture content at which this maximum dry density occurs. These values are essential for field compaction control.

Q7: Is this apparatus suitable for all soil types? A7: While suitable for a wide range of fine-grained and granular soils used in earthwork, the applicability might be limited for very rocky soils or highly organic soils. It’s best used for soils primarily passing a 19mm or 20mm sieve as per standard requirements.

Additional information

| Model Number |

AZA 0865 |

|---|---|

| Test Method |

Heavy Compaction Test (Modified Proctor Compaction Test) |

| Purpose |

To determine the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC) of soils under heavy compaction effort. |

| Material |

Heavy-duty steel |

Related products

AZA 0848 PLASTIC LIMIT SET

AZA 0849 SHRINKAGE LIMIT SET

- Used to determine shrinkage limit of cohesive soils

- Includes high-quality porcelain and stainless-steel tools

- Ideal for geotechnical engineering and soil mechanics labs

- Compact, easy to use, and conforms to IS 2720 standards

- Model: AZA 0849 – Durable and reliable build

- Supplied with a complete set for lab-ready use

AZA 0850 LINEAR SHRINKAGE MOULD

AZA 0851 SOIL CONE PENETROMETER

AZA 0854 LIQUID LIMIT DEVICE (MOTORISED)

AZA 0864 STANDARD COMPACTION TEST

AZA 0869 POCKET PENTROMETER

AZA 0874 RAPID MOISTURE METER

- Rapid Moisture Meter: Utilizes the calcium carbide method for quick determination of moisture content.

- Field-Ready: Ideal for field testing of soils, aggregates, sand, and fine materials.

- Portable & Self-Contained: No external power source required, perfect for on-site quality control.

- Immediate Results: Provides fast, accurate readings, enabling immediate adjustments.

- Durable Construction: Robust design suitable for demanding construction and geotechnical testing environments.

- Azalab Quality: Reliable and efficient tool for rapid soil moisture assessment.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items