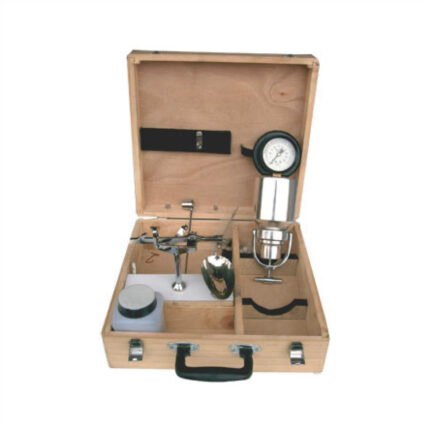

AZA 0901 DIRECT SHEAR (MOTORISED TWELVE SPEED)

- Direct Shear Apparatus: Motorised, high-precision tester for determining soil shear strength.

- Twelve-Speed Motorised: Offers 12 distinct rates of strain for comprehensive testing and research flexibility.

- Soil Shear Strength: Crucial for foundation design, slope stability, and retaining wall analysis.

- Robust Construction: Durable and stable design for reliable long-term laboratory use.

- Standard Compliance: Meets relevant international standards for direct shear testing.

- Azalab Quality: Advanced geotechnical testing equipment for accurate and repeatable results.

Description

AZA 0901: Motorised Twelve-Speed Direct Shear for Soil Shear Strength

The AZA 0901 Direct Shear (Motorised Twelve Speed) from Azalab represents a pinnacle in geotechnical testing equipment, offering unparalleled precision and versatility for determining the soil shear strength of various soil types. This advanced apparatus is indispensable for engineers and researchers involved in critical civil engineering applications such as foundation design, slope stability analysis, and the design of retaining structures. By accurately measuring the shear strength parameters (cohesion ‘c’ and angle of internal friction ‘phi‘), the AZA 0901 provides fundamental data crucial for safe and economical designs.

What sets the AZA 0901 apart is its sophisticated motorised twelve-speed control system. Unlike single-speed or manually operated direct shear machines, this unit allows for a wide range of strain rates, from slow to rapid, ensuring compliance with various international testing standards, including ASTM D3080 and IS 2720 (Part 13). The ability to select from twelve distinct speeds provides immense flexibility for comprehensive research studies on soil behavior under different loading conditions, as well as for precise determination of both peak and residual shear strengths. The consistent and controlled application of shear force, thanks to the motorisation, eliminates human error and variability, leading to highly repeatable and reliable test results.

The direct shear test involves placing a soil specimen within a split shear box, applying a normal load, and then moving one half of the box horizontally relative to the other. The force required to cause shear failure, along with the corresponding displacement, is measured. The AZA 0901 is typically equipped with a load measuring device (such as a proving ring or an electronic load cell) to quantify the shear force and a deformation measuring device (like a dial gauge or LVDT) to record horizontal and vertical displacements. The robust construction of the apparatus ensures minimal deflection and maximum stability during the test, which is crucial for obtaining accurate data. Its design often incorporates precision bearings and guides for smooth, frictionless movement of the shear box.

Understanding soil shear strength is paramount in predicting how soils will perform under stress. It dictates the bearing capacity of foundations, the stability of natural and engineered slopes, and the pressures exerted on retaining walls. The AZA 0901 Direct Shear apparatus plays a vital role in providing the essential data for these analyses, contributing directly to safer and more efficient infrastructure development. Its durability and precision make it an invaluable asset for academic institutions, commercial laboratories, and government agencies. For more in-depth knowledge about direct shear testing principles and applications, authoritative sources such as geotechnical engineering handbooks or standards published by organizations like ASTM International and the International Society for Soil Mechanics and Geotechnical Engineering (ISSMGE) can be highly beneficial. Explore resources related to “Mohr-Coulomb failure criterion” for a deeper understanding of shear strength theories.

By investing in the AZA 0901 Direct Shear (Motorised Twelve Speed), your laboratory gains a high-performance, versatile, and reliable instrument capable of performing highly accurate geotechnical testing. This apparatus empowers you to generate robust soil shear strength data, leading to more informed design decisions and increased confidence in the stability and performance of civil engineering projects.

Specifications for the AZA 0901 Motorised Twelve-Speed Direct Shear

- Model Number: AZA 0901

- Test Type: Direct Shear Test (for soil shear strength)

- Operation: Motorised, constant rate of strain

- Speed Control: Twelve speed settings (e.g., 0.001, 0.002, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.5, 1.0, 1.25, 2.0 mm/min) or similar range, providing high versatility for various soil types and research.

- Normal Load Application: Dead weights and lever arm system (typically up to 8 kg/cm² or more)

- Shear Box Size: Standard sizes (e.g., 60×60 mm, 100×100 mm, or circular samples)

- Measurement Devices:

- Shear Load Measurement: Proving Ring (various capacities, e.g., 200 kg, 500 kg) or Electronic Load Cell with digital readout.

- Horizontal Displacement Measurement: Dial Gauge (e.g., 25 mm travel, 0.01 mm resolution) or LVDT with digital readout.

- Vertical Displacement Measurement: Dial Gauge (e.g., 10 mm travel, 0.01 mm resolution) or LVDT with digital readout.

- Power Supply: Standard electrical supply (e.g., 230V AC, 50Hz)

- Material Construction: Heavy-duty steel frame, precision-machined brass or stainless steel shear box and components.

- Features: Roller bearings for frictionless movement, quick-release couplings for shear box.

- Dimensions: Varies, designed for stable benchtop operation.

FREQUENTLY ASKED QUESTIONS (FAQ) about the AZA 0901 Direct Shear

Q1: What is the main function of the AZA 0901 Direct Shear Apparatus? A1: The AZA 0901 is used to determine the soil shear strength parameters (cohesion ‘c’ and angle of internal friction ‘phi‘) of soils under different normal loads, which is essential for geotechnical testing.

Q2: What is the benefit of the “Twelve Speed” feature on the AZA 0901? A2: The twelve speed settings allow for a wide range of strain rates, enabling precise testing of various soil types and research into rate-dependent soil behavior. This versatility is crucial for achieving accurate and compliant results for soil shear strength.

Q3: What types of soil can be tested with this apparatus? A3: The AZA 0901 Direct Shear is suitable for testing a wide range of soils, including sands, silts, and clays, both remoulded and undisturbed, provided they can be prepared in the shear box.

Q4: How does the AZA 0901 contribute to safe engineering designs? A4: By accurately determining soil shear strength parameters, the AZA 0901 provides critical data for the design of stable foundations, slopes, and retaining structures, directly enhancing the safety and reliability of civil engineering projects.

Q5: Does the AZA 0901 comply with international testing standards? A5: Yes, the AZA 0901 Motorised Twelve Speed Direct Shear is designed to meet or exceed relevant international standards for direct shear testing, such as ASTM D3080 and IS 2720 (Part 13).

Q6: What maintenance is required for the AZA 0901? A6: Regular maintenance includes cleaning the shear box and components, lubricating moving parts, checking for wear and tear, and periodic calibration of the load and displacement measuring devices to ensure continued accuracy for geotechnical testing.

Q7: Can I use this apparatus for both consolidated-drained and consolidated-undrained tests? A7: While direct shear tests are typically consolidated-drained, the ability to control the rate of strain with the twelve speed motorisation allows for some flexibility in testing conditions, though true consolidated-undrained tests are usually performed in a triaxial apparatus.

Additional information

| Model Number |

AZA 0901 |

|---|---|

| Test Type |

Direct Shear Test (for soil shear strength) |

| Operation |

Motorised, constant rate of strain |

| Shear Box Size |

Standard sizes (e.g., 60×60 mm, 100×100 mm, or circular samples) |

| Power Supply |

Standard electrical supply (e.g., 230V AC, 50Hz) |

| Material Construction |

Heavy-duty steel frame, precision-machined brass or stainless steel shear box and components. |

Related products

AZA 0856 GRAIN SIZE ANALYSIS (PIPETTE METHOD)

- Grain size analysis using sedimentation and pipette method

- Ideal for determining particle distribution in fine soils

- Conforms to IS 2720 (Part 4) and ASTM D422

- Includes sedimentation cylinder, pipette, stand, timer

- Accurate and repeatable measurement of soil fractions

- Essential for geotechnical and soil mechanics labs

AZA 0861 MOTORISED SAND EQUIVALENT SHAKER

AZA 0862 PLUMMET BALANCE

AZA 0864 STANDARD COMPACTION TEST

AZA 0868 PROCTOR NEEDLES (SPRING TYPE)

AZA 0872 DYNAMIC CONE PENETROMETER

- Dynamic Cone Penetrometer (DCP): Essential for rapid in-situ testing of soil strength and compaction.

- Pavement Evaluation: Ideal for assessing subgrade, sub-base, and base course layers in road construction.

- Direct Readout: Provides immediate penetration resistance data, correlating to CBR values.

- Portable & User-Friendly: Lightweight and easy to operate, suitable for various field conditions.

- Robust Construction: Durable components for long-lasting performance in demanding geotechnical testing.

AZA 0874 RAPID MOISTURE METER

- Rapid Moisture Meter: Utilizes the calcium carbide method for quick determination of moisture content.

- Field-Ready: Ideal for field testing of soils, aggregates, sand, and fine materials.

- Portable & Self-Contained: No external power source required, perfect for on-site quality control.

- Immediate Results: Provides fast, accurate readings, enabling immediate adjustments.

- Durable Construction: Robust design suitable for demanding construction and geotechnical testing environments.

- Azalab Quality: Reliable and efficient tool for rapid soil moisture assessment.

AZA 0875 INFRARED MOISTURE METER

- Infrared Heating: Utilizes advanced infrared technology for rapid and uniform sample drying.

- Precise Measurement: Delivers highly accurate moisture content results in a fraction of the time.

- Versatile Application: Ideal for various materials including soils, aggregates, chemicals, food products, and more.

- User-Friendly: Features intuitive controls and a clear display for straightforward operation.

- Rapid Analysis: Significantly speeds up testing processes compared to conventional oven drying.

- Azalab Quality: Reliable and efficient instrument for critical quality control and material testing.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items