AZA 0927 WET SIEVE SHAKER

- AZA 0927 Wet Sieve Shaker: Essential for accurate particle size analysis of fine, cohesive materials.

- Utilizes water to wash fines through sieves, preventing agglomeration and clogging.

- Robust, corrosion-resistant construction for wet lab environments.

- Efficient shaking mechanism with integrated water spray system.

- Accommodates standard 200 mm (8-inch) sieves.

- Digital timer for precise test duration control.

- Complies with IS 2720 (Part 4), ASTM D6913, and ASTM C117.

- Crucial for geotechnical, civil, and environmental engineering labs

Description

AZA 0927 Wet Sieve Shaker: Precise Particle Size Analysis for Fine-Grained Materials by Azalab

The Azalab AZA 0927 Wet Sieve Shaker is a specialized laboratory instrument designed for the accurate and efficient determination of particle size distribution in fine-grained soils, aggregates, and other powdered or granular materials that exhibit cohesive properties or contain significant amounts of fine dust. Unlike traditional dry sieving, wet sieving utilizes water to break down agglomerates and wash fine particles through the sieves, ensuring a more complete and reliable separation. This method is indispensable for geotechnical, civil, and environmental engineering laboratories, as well as in industries such as mining, ceramics, and pharmaceuticals across India, where precise particle size data for cohesive materials is critical for quality control and research.

The Imperative of Wet Sieving with the AZA 0927 Wet Sieve Shaker

Dry sieving can be ineffective for materials where fine particles adhere to coarser ones, or where particles tend to clump together due to moisture content or electrostatic forces. This leads to inaccurate results, underestimating the true proportion of fine material. The AZA 0927 Wet Sieve Shaker overcomes these challenges by integrating the mechanical agitation of a sieve shaker with the cleansing action of water.

The process typically involves:

- Sample Preparation: A known mass of the material is prepared, often after an initial dry sieving to remove coarse particles.

- Sieve Stack Assembly: The sample is placed on a stack of test sieves (usually 200 mm or 8-inch diameter), with progressively finer meshes towards the bottom. The bottom-most sieve is typically the 75-micron (No. 200) sieve, which separates the sand fraction from silt and clay. A receiver pan is placed at the bottom.

- Wet Sieving: The assembled sieve stack is placed into the AZA 0927 Wet Sieve Shaker. Water is continuously sprayed over the top sieve, washing the material down through the stack, while the shaker provides a controlled mechanical motion (e.g., rotary and tapping, or orbital action). This combined action effectively dislodges and carries fine particles through the sieve openings.

- Collection and Drying: The fines passing through the finest sieve are collected in the receiver pan (often for further analysis like hydrometer testing). The material retained on each sieve is then dried and weighed.

This method ensures that every particle is exposed to the sieve openings, leading to a more accurate and representative particle size distribution, which is fundamental for understanding soil behavior, filter design, and material blending.

Key Features for Efficient and Accurate Wet Sieving: The Azalab AZA 0927 Wet Sieve Shaker is built for robustness, precision, and reliable performance in a wet environment:

- Corrosion-Resistant Construction: Made from high-quality, corrosion-resistant materials (e.g., stainless steel, powder-coated components) to withstand continuous exposure to water and aggressive samples.

- Powerful Shaking Mechanism: Incorporates an efficient motor and mechanical system to deliver consistent and uniform shaking motion (e.g., combined rotary and tapping, or orbital) ensuring thorough washing and separation of particles.

- Integrated Water Spray System: Features a durable water spray nozzle or spray bar that ensures a controlled and even flow of water over the sieve stack, maximizing washing efficiency and preventing localized clogging.

- Sieve Capacity: Designed to accommodate a standard stack of 200 mm (8-inch) diameter test sieves, typically holding 6-8 sieves plus a lid and receiver pan.

- Digital Timer with Shut-off (Optional): Allows precise setting of the shaking duration, ensuring repeatable test conditions and automatic shut-off upon completion.

- Effective Drainage System: Built-in tray and drain hose for efficient collection and disposal of wash water, keeping the laboratory area clean.

- User-Friendly Controls: Simple and intuitive controls for ease of operation.

- Safety Features: Enclosed design and splash guards to prevent water splash during operation, ensuring a safe working environment.

- Low Maintenance Design: Easy to clean and maintain, minimizing downtime and maximizing productivity.

Applications and Standards Compliance in the Indian Context: The Azalab AZA 0927 Wet Sieve Shaker is an indispensable tool in various fields in India:

- Geotechnical Engineering: Particle size analysis of soils for foundation design, road construction (subgrades, embankments), and earthwork projects.

- Civil Engineering: Quality control of aggregates, sands, and fills used in concrete and asphalt mixes.

- Environmental Engineering: Analysis of sediments, sludge, and contaminated soils.

- Mining and Mineral Processing: Characterization of ores, fines, and tailings.

- Ceramics and Abrasives Industry: Ensuring precise particle size for raw materials.

The AZA 0927 is designed to facilitate tests in strict accordance with leading national and international standards, ensuring the reliability and comparability of test results:

- IS 2720 (Part 4):1985 (Reaffirmed 2021): Indian Standard Method for Determination of Grain Size Analysis (Sieve Analysis) for soils, which includes procedures for wet sieving.

- ASTM D6913: Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis (covering both wet and dry methods).

- ASTM C117: Standard Test Method for Materials Finer than 75-µm (No. 200) Sieve in Mineral Aggregates by Washing.

- Relevant ISO standards for particle size analysis.

Azalab’s Commitment to Quality and Precision: Azalab is dedicated to providing high-quality, precise laboratory equipment that forms the backbone of reliable material testing and analysis. The AZA 0927 Wet Sieve Shaker reflects our commitment to innovation, accuracy, and user satisfaction. We understand the critical role of accurate particle size data in ensuring the performance, stability, and safety of engineering projects. Our instruments are engineered to meet the stringent demands of modern testing laboratories in India and globally, backed by comprehensive customer support and service.

Further Information and Resources: For detailed operational procedures, specific sample preparation guidelines, and the interpretation of particle size distribution curves, users should refer to the product manual, relevant industry standards, and consult with Azalab’s technical support team.

Specifications:

- Model: AZA 0927

- Product Type: Wet Sieve Shaker

- Sieve Diameter Compatibility: Standard 200 mm (8-inch) diameter test sieves.

- Sieve Capacity: Typically accommodates 6 to 8 sieves with lid and receiver pan.

- Shaking Motion: Combined rotary and tapping motion, or orbital motion (specifics vary by model).

- Motor: Robust electric motor designed for continuous operation.

- Power Supply: 230V AC, 50 Hz, Single Phase.

- Timer: Digital timer with selectable duration (e.g., 0-99 minutes), often with auto-shutoff.

- Water Supply: Requires continuous water supply connection (inlet hose).

- Drainage: Integrated water collection tray with drainage outlet (outlet hose).

- Construction Material: Corrosion-resistant materials (e.g., stainless steel, powder-coated steel).

- Safety Features: Splash guard/enclosure for safe operation.

- Dimensions (Approx.): [H x W x D, e.g., 800 x 400 x 500 mm].

- Weight (Approx.): [e.g., 30-50 kg].

- Standards Compliance: IS 2720 (Part 4), ASTM D6913, ASTM C117, relevant ISO standards.

- Country of Origin: Made in India.

- Included Accessories: Water spray nozzle, connecting hoses, user manual. (Test sieves are typically sold separately).

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What is the primary application of the AZA 0927 Wet Sieve Shaker?

- A: It is used for determining the particle size distribution of fine-grained soils, aggregates, and other materials where dry sieving is ineffective due to cohesion or fine dust.

- Q: Why is wet sieving necessary over dry sieving for some materials?

- A: Wet sieving is necessary for cohesive soils or materials with fines that clump together, as water helps to break down agglomerates and wash fine particles through the sieves, ensuring accurate separation.

- Q: What sieve sizes are compatible with the AZA 0927?

- A: It is designed to accommodate standard 200 mm (8-inch) diameter test sieves.

- Q: Does the machine have a timer?

- A: Many models come with a digital timer for precise control of the shaking duration.

- Q: What standards does the AZA 0927 comply with?

- A: It complies with major standards like IS 2720 (Part 4), ASTM D6913, and ASTM C117.

- Q: Is water supply and drainage required for operation?

- A: Yes, a continuous water supply and an efficient drainage system are essential for proper wet sieving operation.

Additional information

| Model |

AZA 0927 |

|---|---|

| Product Type |

Wet Sieve Shaker |

| Sieve Diameter Compatibility |

Standard 200 mm (8-inch) diameter test sieves. |

| Dimensions (Approx.) |

[H x W x D, e.g., 800 x 400 x 500 mm]. |

| Weight (Approx.) |

[e.g., 30-50 kg] |

| Country of Origin |

Made in India |

| Safety Features |

Splash guard/enclosure for safe operation. |

Related products

AZA 0853 LIQUID LIMIT DEVICE WITH COUNTER

AZA 0857 PARTICLE SIZE SEDIMENTATION (HYDROMETER METHOD)

- Particle size distribution using hydrometer sedimentation

- Suitable for clays and silts below 75 microns

- Conforms to IS 2720 Part IV & ASTM D422

- Includes hydrometer, sedimentation cylinder, thermometer

- Accurate readings of soil particle settlement over time

- Ideal for soil mechanics, civil and geotechnical labs

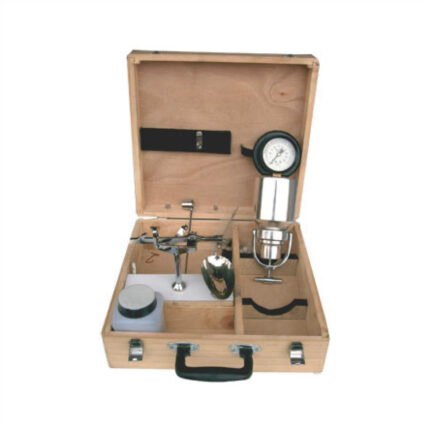

AZA 0859 SAND EQUIVALENT TEST SET

- Evaluates relative proportion of sand vs clay/silt in fine aggregates

- Complies with ASTM D2419 and IS 2720 standards

- Includes graduated cylinder, irrigator tube, siphon assembly

- Portable and easy to operate in field or lab

- Improves quality control in construction and roadwork

- Ideal for geotechnical and civil testing laboratories

- Optional : Stock solution can be supplied at an extra cost

AZA 0865 HEAVY COMPACTION TEST

- Heavy Compaction Test: Specifically designed to perform the Modified Proctor Compaction Test.

- High Compaction Energy: Utilizes a heavier hammer and greater drop height for higher soil density requirements.

- Crucial for Critical Projects: Essential for quality control in heavy civil engineering applications like airfields and high-stress pavements.

- Complete Apparatus: Includes a robust compaction mould, heavy rammer, and necessary accessories.

- Standard Compliant: Adheres to international standards such as ASTM D1557 and equivalent IS/BS norms.

- Azalab Quality: Durable and precise equipment for reliable geotechnical testing results.

AZA 0868 PROCTOR NEEDLES (SPRING TYPE)

AZA 0871 WATER LEVEL INDICATOR

- Water Level Indicator: Essential instrument for accurate measurement of groundwater levels.

- Versatile Use: Ideal for monitoring water levels in boreholes, standpipes, wells, and observation tubes.

- Precise Detection: Features a sensitive probe that provides clear audible and visual indication upon contact with water.

- Graduated Cable: High-accuracy, durable cable with clear markings for precise depth readings.

- Portable & Robust: Designed for demanding field monitoring in environmental, hydrological, and geotechnical applications.

- Azalab Quality: Reliable and easy-to-use equipment for consistent groundwater monitoring.

AZA 0872 DYNAMIC CONE PENETROMETER

- Dynamic Cone Penetrometer (DCP): Essential for rapid in-situ testing of soil strength and compaction.

- Pavement Evaluation: Ideal for assessing subgrade, sub-base, and base course layers in road construction.

- Direct Readout: Provides immediate penetration resistance data, correlating to CBR values.

- Portable & User-Friendly: Lightweight and easy to operate, suitable for various field conditions.

- Robust Construction: Durable components for long-lasting performance in demanding geotechnical testing.

AZA 0874 RAPID MOISTURE METER

- Rapid Moisture Meter: Utilizes the calcium carbide method for quick determination of moisture content.

- Field-Ready: Ideal for field testing of soils, aggregates, sand, and fine materials.

- Portable & Self-Contained: No external power source required, perfect for on-site quality control.

- Immediate Results: Provides fast, accurate readings, enabling immediate adjustments.

- Durable Construction: Robust design suitable for demanding construction and geotechnical testing environments.

- Azalab Quality: Reliable and efficient tool for rapid soil moisture assessment.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items