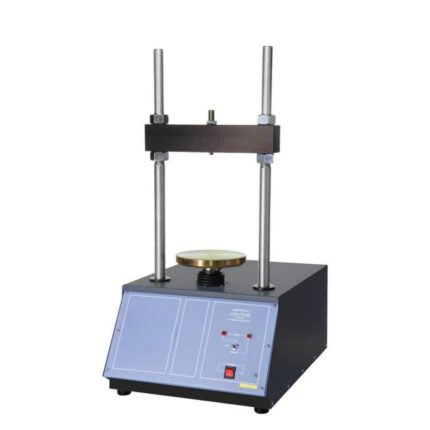

AZA 0932 RING AND BALL APPARATUS

- AZA 0932 Ring and Ball Apparatus: Manual softening point tester for bitumen.

- Robust steel construction with clear glass beaker.

- Includes standard brass rings, steel balls, and hand stirrer.

- Complies with IS 1205, ASTM D36, EN 1427, IP 58/63.

- Essential for quality control of bitumen in hot climates.

- Cost-effective solution for reliable softening point determination.

- Requires external heat source and thermometers (sold separately).

Description

AZA 0932 Ring & Ball Apparatus: Essential Manual Softening Point Testing by AzalabAZA 0932 Ring and Ball Apparatus, Azalab, manual softening point, bitumen testing, IS 1205, ASTM D36

The Azalab AZA 0932 Ring & Ball Apparatus is a foundational laboratory instrument specifically designed for the determination of the softening point of bitumen, road tars, and other similar bituminous materials. This test is of paramount importance in the civil engineering and road construction sectors, especially in countries like India with widely varying climatic conditions. The softening point indicates the temperature at which a bituminous material transitions from a semi-solid to a more fluid state, providing a crucial parameter for understanding its temperature susceptibility and high-temperature performance characteristics. The AZA 0932 Ring & Ball Apparatus provides a robust and reliable manual setup for this critical quality control test, adhering to established international and Indian standards.

Understanding the Softening Point with the AZA 0932 Ring and Ball ApparatusAZA 0932 Ring and Ball Apparatus, Azalab, manual softening point, bitumen testing, IS 1205, ASTM D36

Bitumen, being a viscoelastic material, does not possess a distinct melting point; instead, it gradually softens as temperature increases. The Ring and Ball method, which the AZA 0932 facilitates, defines the softening point as the temperature at which a standard steel ball, loaded onto a bitumen disc held within a brass ring, causes the softened bitumen to drop a specified distance (25.0 mm) when heated under controlled conditions. This test is vital for:

- Bitumen Grading and Selection: Helping engineers choose the appropriate grade of bitumen that can withstand high ambient temperatures without excessive softening and rutting, a common concern in warmer regions of India.

- Quality Control: Ensuring that the consistency and thermal properties of bitumen batches meet design specifications.

- Pavement Performance Prediction: Providing insights into how an asphalt pavement will behave under various service temperatures, contributing to the prevention of premature pavement distress.

Robust Design and Manual Operation for Reliability: The AZA 0932 Ring & Ball Apparatus is built for durability and straightforward operation, making it a staple in many testing laboratories. Its manual nature ensures that operators gain a direct understanding of the test process, while its robust construction guarantees long-term performance.

- Sturdy Construction: The apparatus consists of a rigid steel bracket with a sliding plate support, designed to hold the components securely and ensure stability during the heating process.

- Precision Positioning: The support plate features dedicated holes for precisely positioning the brass rings, ball guides, and a central opening for inserting a thermometer. This setup ensures that the test conditions adhere strictly to standard requirements.

- Hand Stirrer: A manual hand stirrer is included to ensure uniform temperature distribution throughout the liquid bath. Consistent stirring is essential to maintain the specified heating rate and achieve accurate results.

- Clear Observation: The open design allows for clear visual observation of the bitumen softening and the precise moment the steel ball drops to the bottom plate, enabling the operator to manually record the softening point temperature.

- Cost-Effective Solution: As a manual apparatus, the AZA 0932 provides a cost-effective solution for laboratories requiring standard-compliant softening point determination without the need for advanced automation.

Key Components of the AZA 0932: The Azalab AZA 0932 Ring & Ball Apparatus typically includes the following standard components necessary for conducting the test:

- Steel Bracket Assembly: A robust stand with a sliding support plate for holding test components.

- Glass Beaker: An approximate 600ml heat-resistant glass beaker that serves as the liquid bath (water for softening points below 80°C, glycerin for those above).

- Brass Rings: Two precisely machined brass rings of standard dimensions (e.g., 20.0 mm ID, 22.0 mm OD, 6.4 mm height) as per relevant standards.

- Steel Balls: Two steel balls, each 9.5 mm in diameter and weighing 3.5 ± 0.05 grams.

- Ball Guides: Used to center the steel balls on top of the bitumen samples in the rings.

- Hand Stirrer: For manual agitation of the bath liquid.

- Note: Essential accessories such as standard thermometers (e.g., ASTM 15C and 16C, or equivalent as per IS 1205/IP 58) and an external heating source (like a Bunsen burner or an electric hot plate) are typically required but supplied separately.

Compliance with Indian and International Standards: The Azalab AZA 0932 Ring & Ball Apparatus is manufactured to conform to leading international and Indian standards for bitumen testing, ensuring that the results are reliable and globally recognized:

- IS 1205:1985: Indian Standard Method for Determination of Softening Point of Tar and Bituminous Materials.

- ASTM D36: Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus).

- EN 1427: Bitumen and bituminous binders – Determination of softening point – Ring and Ball method.

- IP 58/63: Institute of Petroleum standard.

- AASHTO T53: Standard Method of Test for Softening Point of Bituminous Materials (Ring-and-Ball Apparatus). Compliance with these standards is critical for quality assurance and material specification in the Indian road construction sector, where bitumen performance is paramount for durable infrastructure.

Azalab’s Commitment to Quality: Azalab is committed to delivering high-quality, precise laboratory equipment that supports critical analysis in civil engineering and materials science. The AZA 0932 Ring & Ball Apparatus embodies this commitment by offering a reliable and straightforward solution for a vital bitumen test. We understand the importance of accurate material characterization for ensuring the safety, performance, and longevity of infrastructure projects. Our instruments are built to high standards and backed by comprehensive customer support.

Further Information and Resources: For detailed operational procedures, specific sample preparation guidelines, and safety precautions (especially when handling hot bitumen and bath liquids), users should always refer to the latest versions of applicable standards such as IS 1205, ASTM D36, or EN 1427. Additional technical information, user manuals, and details on compatible accessories can be found on the Azalab official website.

Specifications:

- Model: AZA 0932

- Operation: Manual (requires external heating source and manual observation)

- Test Method: Ring and Ball Method

- Primary Application: Determination of Softening Point of Bitumen and Bituminous Binders.

- Temperature Range: Ambient to approx. 150°C (depending on heating bath liquid).

- Heating Method: Manual (using external heat source, e.g., Bunsen burner or hot plate, not included).

- Temperature Observation: Manual (using standard thermometers, not included).

- Ball Drop Observation: Manual visual observation.

- Components Included (Typical Assembly):

- Steel Bracket with Sliding Plate Support.

- Glass Beaker (approx. 600 ml, heat-resistant glass).

- Brass Rings (2 Nos., standard dimensions as per IS 1205/ASTM D36).

- Steel Balls (2 Nos., 9.5 mm dia., 3.50 ± 0.05 g weight).

- Ball Guides (often integral to support plate).

- Hand Stirrer.

- Standards Compliance: IS 1205:1985, ASTM D36, EN 1427, IP 58/63, AASHTO T53 (check specific model for full compliance details).

- Material: Durable metal construction with high-quality glassware.

- Dimensions (Approx.): Compact benchtop design.

- Weight (Approx.): [Insert Weight, e.g., 2-4] kg (excluding accessories and liquid).

- Country of Origin: Made in India.

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What is the primary purpose of the AZA 0932 Ring & Ball Apparatus?

- A: It is used to determine the softening point of bitumen and other bituminous materials, indicating their temperature susceptibility.

- Q: Is the AZA 0932 an automatic or manual apparatus?

- A: The AZA 0932 is a manual apparatus, requiring the operator to control the heating rate (via an external heat source) and observe the ball drop manually.

- Q: What standards does the AZA 0932 comply with?

- A: It complies with key standards like IS 1205:1985, ASTM D36, EN 1427, IP 58/63, and AASHTO T53.

- Q: Why is the softening point test important for bitumen in India?

- A: India experiences diverse climatic conditions. A higher softening point is preferred for bitumen used in warmer regions to ensure the pavement resists rutting and deformation under high temperatures, making this test crucial for material selection and performance.

- Q: What are the standard components of a manual Ring and Ball apparatus?

- A: It typically includes a steel bracket with support, glass beaker, brass rings, steel balls, ball guides, and a hand stirrer. Thermometers and an external heat source are essential accessories, not included with this base apparatus.

- Q: What type of liquid bath is used, and why?

- A: Distilled water is used for softening points up to 80°C. For softening points above 80°C, glycerin is used because water would boil before the bitumen softens.

Additional information

| Model |

AZA 0932 |

|---|---|

| Operation |

Manual (requires external heating source and manual observation) |

| Test Method |

Ring and Ball Method |

| Material |

Durable metal construction with high-quality glassware. |

| Dimensions (Approx.) |

Compact benchtop design. |

| Ball Drop Observation: |

Manual visual observation. |

Related products

AZA 0933 RING AND BALL APPARATUS (ELECTRICAL)

- AZA 0933 Ring & Ball Apparatus (Electrical): For bitumen softening point.

- Features electrically controlled 5°C/min heating rate.

- Digital temperature display with integrated magnetic stirrer.

- Complies with ASTM D36, EN 1427, and AASHTO T53.

- Ensures consistent heating and uniform bath temperature.

- Reliable and safer alternative to open-flame heating.

- Essential for asphalt quality control to predict high-temp performance. Here's the detailed content for the Azalab AZA 0933 Ring & Ball Apparatus (Electrical)

AZA 0934 RING & BALL APPARATUS(SEMI AUTOMATIC)

- AZA 0934 Ring & Ball Apparatus (Semi-Automatic): For bitumen softening point.

- Microprocessor-controlled 5°C/min heating rate.

- Digital temperature display and automatic ball drop detection.

- Complies with ASTM D36, EN 1427, and AASHTO T53.

- Ensures accurate assessment of high-temperature bitumen performance.

- Integrated magnetic stirrer for uniform bath temperature.

- Enhances precision and efficiency in asphalt quality control

AZA 0943 STRIPPING VALUE APPARATUS

AZA 0944 CENTRIFUGE EXTRACTOR (HAND OPERATED)

- AZA 0944 Hand Centrifuge: For accurate bitumen content determination.

- Manual hand-crank operation; no external power needed.

- Durable cast aluminum construction for longevity.

- Ideal for asphalt and road paving mixture analysis.

- Removable aluminum bowl for easy sample handling & cleaning.

- Essential tool for civil engineering and material testing labs.

- Ensures quality control in road construction projects

AZA 0945 CENTRIFUGE EXTRACTOR (MOTORISED)

AZA 0946 CENTRIFUGE EXTRACTOR (MOTORISED)

- Motorised Operation: Eliminates manual effort, ensuring consistent and precise extraction.

- Accurate Bitumen Content: Determines bitumen percentage in bituminous mixtures with high precision.

- Variable Speed Control: Offers electronic control of bowl speed from 0 to 3600 RPM for optimized extraction.

- Safety Features: Includes automatic fast stop and robust construction for safe laboratory use.

- Standard Compliant: Meets ASTM D2172, AASHTO T-58, T-164 for reliable testing.

AZA 0953 MARSHALL STABILITY TEST APPARATUS

- Manual Operation: Reliable and cost-effective method for Marshall stability and flow testing.

- Precision Measurement: Features a proving ring and dial gauge for accurate readings.

- Standard Compliant: Adheres to essential asphalt mix design and testing standards.

- Durable Construction: Built for rigorous use in laboratory and field environments.

- Fundamental QC Tool: Indispensable for evaluating asphalt mix performance and optimizing designs

AZA 0959 STRAIGHT EDGE (3 Meters)

- Pavement Regularity Check: Precisely identifies undulations and irregularities on road surfaces.

- Optimal Length: 3-meter length covers sufficient road sections for effective assessment.

- Lightweight & Durable: Constructed from high-grade aluminum for easy handling and long life.

- Essential for QC: Key tool for ensuring riding comfort, safety, and proper drainage.

- Standard Compliant: Adheres to critical national road construction quality standards

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items