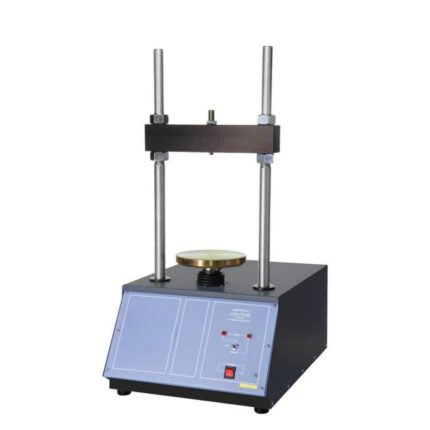

AZA 0935 FRAASS BREAKING POINT APPARATUS

- AZA 0935 Fraass Breaking Point Apparatus: Determines bitumen’s brittle temperature.

- Critical for assessing low-temperature asphalt performance.

- Includes precise mechanical flexing device and cooling bath.

- Complies with EN 12593 international standard.

- Ensures selection of suitable bitumen for cold climates.

- Robust construction for reliable laboratory use.

- Measures temperature at which bitumen film cracks

Description

AZA 0935 Fraass Breaking Point Apparatus: Assessing Bitumen Brittle Behavior in Cold Climates by Azalab

The Azalab AZA 0935 Fraass Breaking Point Apparatus is a highly specialized and critical laboratory instrument designed for accurately determining the Fraass Breaking Point of bitumen and bituminous binders. This test is paramount in evaluating the low-temperature performance of asphalt materials, particularly in regions prone to cold weather. It measures the temperature at which a thin film of bitumen becomes brittle and fractures under prescribed cooling and flexing conditions. Understanding the Fraass Breaking Point is essential for engineers and material scientists to select appropriate bitumen grades that can withstand thermal stresses and prevent low-temperature cracking in asphalt pavements, thereby ensuring their durability and longevity in diverse climatic conditions.

The Significance of the AZA 0935 Fraass Breaking Point Apparatus in Material Characterization

The Fraass Breaking Point is a key indicator of a bitumen’s low-temperature flexibility and its susceptibility to brittle fracture. Bituminous materials, being viscoelastic, become harder and more brittle as temperatures drop. Below a certain temperature, known as the breaking point, they lose their elasticity and behave more like a brittle solid. In asphalt pavements, this can lead to thermal cracking when the material is subjected to temperature-induced stresses, compromising the integrity and service life of the road. The AZA 0935 Fraass Breaking Point Apparatus precisely identifies this critical transition temperature, providing crucial data for:

- Bitumen Selection: Guiding the choice of bitumen grades suitable for specific cold climate applications.

- Pavement Design: Informing pavement engineers about the low-temperature performance characteristics of materials.

- Quality Control: Ensuring that manufactured bitumen products meet the required specifications for low-temperature flexibility.

Principle of Operation: The Fraass Method: The Fraass test involves coating a thin, standardized film of bitumen onto a polished steel plaque. This plaque is then clamped into a testing frame within a cooling bath. The apparatus is cooled at a controlled rate, typically 1°C per minute. Throughout the cooling process, the bitumen-coated plaque is repeatedly flexed at a constant rate (e.g., once every minute) by a mechanical device. The test continues until the first crack or fracture is visually observed in the bitumen film. The temperature at which this fracture occurs is recorded as the Fraass Breaking Point. The AZA 0935 ensures precise control over cooling rate and flexing action, which are critical for repeatable results.

Key Features for Accurate and Reliable Testing: The Azalab AZA 0935 Fraass Breaking Point Apparatus is designed with precision components to ensure reliable and accurate results:

- Flexing Device: A robust mechanical system that repeatedly flexes the steel plaque at a uniform rate, typically controlled by a hand-operated crank or a motorized mechanism (for semi-automatic versions).

- Cooling System: Consists of an insulated double-walled test tube or Dewar flask, designed to hold a cooling medium (e.g., dry ice with alcohol, or a cryostat fluid). The insulation ensures stable and uniform cooling.

- Temperature Measurement: High-precision liquid-in-glass thermometer (e.g., ASTM 64C or equivalent, -38°C to +40°C) is typically used for direct measurement of the cooling bath temperature, ensuring accuracy. Digital thermometers may be integrated in more advanced models.

- Steel Plaques/Strips: Standardized flexible steel plaques (e.g., 41 x 20 x 0.15 mm) specifically designed for applying the bitumen film.

- Molding Plate: A brass or metal plate used to ensure the bitumen film is of uniform thickness on the plaque.

- Viewing Window: Some models incorporate a clear viewing window or a light source to aid in observing the first crack in the bitumen film.

- Robust Construction: Made from high-quality materials to withstand low temperatures and repetitive flexing, ensuring long-term durability and consistent performance.

Adherence to International Standards: The Azalab AZA 0935 Fraass Breaking Point Apparatus is meticulously manufactured to comply with key international standards for bitumen testing. The primary standard for this test is:

- EN 12593: Bitumen and bituminous binders – Determination of the Fraass breaking point. Compliance with EN 12593 ensures that test results obtained from the AZA 0935 are consistent, comparable, and accepted by industry professionals and regulatory bodies across Europe and globally. This adherence is crucial for quality assurance and material specification in the asphalt and road construction industries.

The Azalab Commitment to Quality and Performance: Azalab is dedicated to providing high-quality, precise laboratory equipment that supports critical analysis in civil engineering and materials science. The AZA 0935 Fraass Breaking Point Apparatus exemplifies this commitment, offering a robust, accurate, and reliable solution for assessing the low-temperature behavior of bitumen. We understand the critical role of precise material characterization in ensuring the safety, performance, and longevity of infrastructure. Our instruments are built to high standards, ensuring long-term performance and backed by comprehensive customer support.

Further Information and Resources: For detailed operational procedures, preparation of bitumen samples, and safety precautions related to handling cooling media, users should refer to the latest version of EN 12593. Additional technical information, user manuals, and details on compatible accessories can be found on the Azalab official website.

Specifications:

- Model: AZA 0935

- Test Method: Fraass Breaking Point (Brittle Point)

- Primary Application: Low-temperature performance assessment of bitumen and bituminous binders.

- Operating Temperature Range: Typically down to -30°C or -40°C (depending on cooling medium).

- Cooling Rate: Controlled at 1°C per minute.

- Flexing Rate: One flex cycle per minute.

- Components Included (Typical Assembly):

- Flexing Device: Mechanical bending apparatus with a hand-operated crank (or motorized in advanced versions).

- Cooling Bath/Tube: Insulated double-walled glass tube or Dewar flask.

- Thermometer: High-precision liquid-in-glass thermometer (e.g., ASTM 64C or equivalent, range -38°C to +40°C).

- Steel Plaques/Strips: Standardized flexible steel strips (e.g., 41 x 20 x 0.15 mm).

- Molding Plate: For uniform coating of bitumen on plaques.

- Support Hardware: Clamps and stands for assembly.

- Standards Compliance: EN 12593 (check specific model for full compliance details).

- Material: High-quality metal and glass components for durability in cold conditions.

- Dimensions (Approx.): [Insert W x D x H, e.g., 200 x 200 x 400] mm (assembled apparatus).

- Weight (Approx.): [Insert Weight, e.g., 3-5] kg.

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What is the primary purpose of the AZA 0935 Fraass Breaking Point Apparatus?

- A: It determines the temperature at which bitumen becomes brittle and cracks when subjected to specified cooling and flexing conditions.

- Q: Why is the Fraass Breaking Point important for bitumen?

- A: It is crucial for assessing bitumen’s low-temperature flexibility and resistance to thermal cracking, especially in cold climates.

- Q: What standard does the AZA 0935 comply with?

- A: It is designed to comply with EN 12593 (Bitumen and bituminous binders – Determination of the Fraass breaking point).

- Q: What kind of cooling medium is typically used?

- A: Dry ice with alcohol (e.g., methanol or ethanol) is commonly used to achieve the required low temperatures.

- Q: What is the significance of the steel plaque?

- A: The bitumen is coated onto a standardized steel plaque, which is then flexed to induce cracking, allowing the breaking point to be observed.

Additional information

| Model |

AZA 0935 |

|---|---|

| Test Method |

Fraass Breaking Point (Brittle Point) |

| Primary Application |

Low-temperature performance assessment of bitumen and bituminous binders. |

| Cooling Rate |

Controlled at 1°C per minute. |

| Flexing Rate |

One flex cycle per minute. |

| Weight (Approx.) |

[Insert Weight, e.g., 3-5] kg |

Related products

AZA 0932 RING AND BALL APPARATUS

- AZA 0932 Ring and Ball Apparatus: Manual softening point tester for bitumen.

- Robust steel construction with clear glass beaker.

- Includes standard brass rings, steel balls, and hand stirrer.

- Complies with IS 1205, ASTM D36, EN 1427, IP 58/63.

- Essential for quality control of bitumen in hot climates.

- Cost-effective solution for reliable softening point determination.

- Requires external heat source and thermometers (sold separately).

AZA 0934 RING & BALL APPARATUS(SEMI AUTOMATIC)

- AZA 0934 Ring & Ball Apparatus (Semi-Automatic): For bitumen softening point.

- Microprocessor-controlled 5°C/min heating rate.

- Digital temperature display and automatic ball drop detection.

- Complies with ASTM D36, EN 1427, and AASHTO T53.

- Ensures accurate assessment of high-temperature bitumen performance.

- Integrated magnetic stirrer for uniform bath temperature.

- Enhances precision and efficiency in asphalt quality control

AZA 0936 WATER IN BITUMINOUS MATERIAL (DEAN-STARK)

- AZA 0936 Water in Bituminous Material Dean-Stark: Accurate water content testing.

- Utilizes the reliable Dean-Stark distillation method.

- Includes distillation flask, graduated trap, and reflux condenser.

- Essential for quality control of asphalt, bitumen, and road materials.

- Complies with ASTM D95, EN 1428, and AASHTO T55 standards.

- Ensures material quality and pavement durability.

- Robust borosilicate glass components for lab use

AZA 0939 DIGITAL PENETROMETER

- AZA 0939 Digital Penetrometer: For precise bitumen consistency testing.

- High-resolution 0.01 mm digital display.

- Programmable electronic timer for automatic penetration.

- Complies with ASTM D5, EN 1426, and other global standards.

- Minimizes human error, ensuring accurate & repeatable results.

- Robust design with fine adjustment, illumination & magnifier.

- Essential for quality control in asphalt and petroleum industries

AZA 0950 SAY BOLT VISCOMETER

- Empirical Viscosity: Measures flow time (efflux time) of liquids through a calibrated orifice.

- Dual Orifices: Typically equipped for both Saybolt Universal Viscosity (SUV) and Saybolt Furol Viscosity (SFV).

- Temperature Controlled: Features a precise heating system to maintain sample temperature during testing.

- Wide Application: Essential for testing lubricants, fuel oils, asphalt binders, and other petroleum products.

- Standard Compliant: Adheres to ASTM D88, AASHTO T72, and relevant IS standards for consistency.

AZA 0953 MARSHALL STABILITY TEST APPARATUS

- Manual Operation: Reliable and cost-effective method for Marshall stability and flow testing.

- Precision Measurement: Features a proving ring and dial gauge for accurate readings.

- Standard Compliant: Adheres to essential asphalt mix design and testing standards.

- Durable Construction: Built for rigorous use in laboratory and field environments.

- Fundamental QC Tool: Indispensable for evaluating asphalt mix performance and optimizing designs

AZA 0954 AUTOMATIC MARSHALL STABILITY TEST MACHINE

- Automated Testing: Provides precise, consistent measurement of Marshall stability and flow.

- Digital Data Acquisition: Captures and processes test results digitally for analysis.

- Enhanced Accuracy: Eliminates human error, ensuring highly reproducible results.

- Compliance: Meets ASTM D6927, AASHTO T283, and IS 2720 Part 10 standards.

- Crucial for Pavement Design: Essential for optimizing asphalt mix proportions and performance

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items