AZA 0936 WATER IN BITUMINOUS MATERIAL (DEAN-STARK)

- AZA 0936 Water in Bituminous Material Dean-Stark: Accurate water content testing.

- Utilizes the reliable Dean-Stark distillation method.

- Includes distillation flask, graduated trap, and reflux condenser.

- Essential for quality control of asphalt, bitumen, and road materials.

- Complies with ASTM D95, EN 1428, and AASHTO T55 standards.

- Ensures material quality and pavement durability.

- Robust borosilicate glass components for lab use

Description

AZA 0936 Water in Bituminous Material (Dean-Stark): Accurate Moisture Determination by Azalab

The Azalab AZA 0936 Water in Bituminous Material (Dean-Stark) apparatus is a specialized and essential laboratory instrument designed for the precise determination of water content in a wide range of bituminous materials, including asphalt, road oils, cut-back asphalts, and other similar products AZA 0936 Water in Bituminous Material Dean-Stark, Azalab, water content bitumen, Dean-Stark method, asphalt testing, ASTM D95. The presence of water in bituminous materials can significantly impact their properties, performance, and interaction with aggregates, leading to issues like poor adhesion, stripping, and reduced durability of asphalt pavements. Utilizing the internationally recognized Dean-Stark distillation method, the AZA 0936 provides a reliable and accurate means for quality control in road construction, civil engineering, and material production.

Principles of the AZA 0936 Water in Bituminous Material Dean-Stark Method

The Dean-Stark method, also known as the azeotropic distillation method, is a gravimetric technique that involves co-distilling the water present in a sample with a water-immiscible solvent (such as xylene, toluene, or petroleum naphtha) that has a boiling point slightly above that of water. The process employed by the AZA 0936 apparatus works as follows:

- Sample Preparation: A known mass of the bituminous material is placed in a distillation flask along with a measured volume of the solvent.

- Heating and Vaporization: The flask is heated, causing both the water and the solvent to vaporize.

- Condensation: The mixed vapors travel upwards into a reflux condenser, where they are cooled by circulating water and condense back into liquid form.

- Collection in Trap: The condensed liquid (a mixture of water and solvent) flows into a precisely calibrated Dean-Stark trap.

- Separation and Measurement: Since water and the solvent are immiscible, the water, being denser, settles at the bottom of the graduated trap, while the lighter solvent overflows from the top of the trap and returns to the distillation flask, creating a continuous reflux cycle.

- Direct Reading: Once distillation is complete and no more water collects in the trap, the volume of water collected is directly read from the graduations on the trap. This volume, converted to a percentage by weight or volume of the original sample, represents the water content. This method is highly effective because it ensures complete recovery of the water from the sample, providing accurate and repeatable results.

Key Components for Robust Performance: The Azalab AZA 0936 apparatus is a complete assembly designed for robust and reliable operation:

- Distillation Flask: Typically a round-bottom flask (e.g., 500 ml or 1000 ml capacity), made of high-quality borosilicate glass, capable of withstanding the heat cycles.

- Dean-Stark Graduated Trap: This specialized receiver, made of borosilicate glass, features precise graduations (e.g., 0.1 ml divisions for a 10 ml capacity) allowing for accurate measurement of the collected water volume.

- Reflux Condenser: A water-cooled condenser (e.g., Liebig or West type) ensures efficient cooling and condensation of the vapors, preventing solvent loss and ensuring complete water recovery.

- Heating System: An electric heating mantle or hot plate with an energy regulator or temperature controller provides uniform and controllable heating to the distillation flask, crucial for a steady distillation rate.

- Supporting Hardware: Includes a sturdy laboratory stand, clamps, and necessary adapters (e.g., corks or PTFE seals) to securely assemble the glassware and maintain stability during the test.

- Thermometer (Optional/External): A thermometer is often used to monitor the vapor temperature, ensuring the correct boiling range of the solvent and water mixture.

Adherence to Global Standards: The Azalab AZA 0936 Water in Bituminous Material (Dean-Stark) apparatus is manufactured to comply with leading international standards for water content determination. These typically include:

- ASTM D95: Standard Test Method for Water in Petroleum Products and Bituminous Materials by Distillation.

- EN 1428: Bitumen and bituminous binders – Determination of water content in bituminous emulsions by distillation.

- AASHTO T55: Standard Method of Test for Water in Petroleum Products and Bituminous Materials by Distillation. Compliance with these standards ensures that the test results are reliable, comparable, and accepted by industry professionals and regulatory bodies worldwide, making the AZA 0936 an indispensable tool for quality assurance and material specification.

The Azalab Commitment to Precision and Quality: Azalab is dedicated to providing high-quality, precise laboratory equipment that supports critical analysis in civil engineering and materials science. The AZA 0936 Water in Bituminous Material (Dean-Stark) apparatus exemplifies this commitment, offering a robust, accurate, and reliable solution for a vital test. We understand the importance of precise material characterization for ensuring the safety, performance, and longevity of infrastructure. Our instruments are built to high standards, ensuring long-term performance and backed by comprehensive customer support.

Further Information and Resources: For detailed operational procedures, specific solvent recommendations, and safety precautions (including proper ventilation when using solvents), users should refer to the latest versions of applicable standards such as ASTM D95 or EN 1428. Additional technical information, user manuals, and details on compatible accessories can be found on the Azalab official website.

Specifications:

- Model: AZA 0936

- Test Method: Dean-Stark (Azeotropic Distillation)

- Primary Application: Determination of water content in bituminous materials.

- Components Included (Typical Assembly):

- Distillation Flask: Round-bottom, borosilicate glass (e.g., 500 ml or 1000 ml capacity).

- Dean-Stark Trap: Graduated, borosilicate glass (e.g., 10 ml capacity, 0.1 ml divisions, or specific capacity per standard).

- Reflux Condenser: Liebig or West type, borosilicate glass, water-cooled.

- Heating Device: Electric Heating Mantle or Hot Plate with Energy Regulator/Controller (suitable for flask size).

- Support Hardware: Laboratory Stand, Clamps, Bossheads, Adapters (e.g., corks or ground glass joints).

- Standards Compliance: ASTM D95, EN 1428, AASHTO T55, IP 74, IS 1448 (P:53) (check specific model for full compliance details).

- Material (Glassware): High-quality Borosilicate Glass.

- Power Supply (for heater): Typically 230V, 50/60 Hz, Single Phase (confirm specific model).

- Dimensions (Approx.): [Insert W x D x H, e.g., 300 x 300 x 700] mm (assembled apparatus).

- Weight (Approx.): [Insert Weight, e.g., 5-8] kg.

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What is the primary use of the AZA 0936 Dean-Stark apparatus?

- A: It is used to accurately determine the water content in various bituminous materials like asphalt, road oils, and cut-back asphalts.

- Q: How does the Dean-Stark method work?

- A: It involves co-distilling the water with a water-immiscible solvent; the water then separates and collects in a graduated trap for direct volume measurement.

- Q: What standards does the AZA 0936 comply with?

- A: It is designed to comply with international standards such as ASTM D95, EN 1428, and AASHTO T55.

- Q: What capacity Dean-Stark trap is typically included?

- A: Common trap capacities are 5 ml, 10 ml, or 25 ml, with precise graduations. The AZA 0936 usually includes the standard trap for the specified test.

- Q: Why is it important to measure water content in bitumen?

- A: Excess water can negatively affect bitumen’s adhesion to aggregate, mix workability, and the overall durability and performance of asphalt pavements.

Additional information

| Model |

AZA 0936 |

|---|---|

| Test Method |

Dean-Stark (Azeotropic Distillation) |

| Primary ApplicationDetermiMaterial (Glassware) |

High-quality Borosilicate Glass. |

| Power Supply (for heater) |

Typically 230V, 50/60 Hz, Single Phase (confirm specific model).nation of water content in bituminous materials. |

| Material (Glassware) |

High-quality Borosilicate Glass. |

Related products

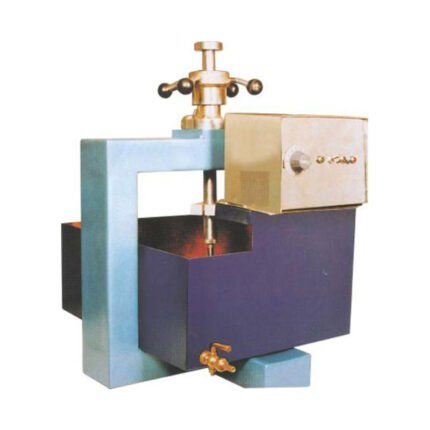

AZA 0933 RING AND BALL APPARATUS (ELECTRICAL)

- AZA 0933 Ring & Ball Apparatus (Electrical): For bitumen softening point.

- Features electrically controlled 5°C/min heating rate.

- Digital temperature display with integrated magnetic stirrer.

- Complies with ASTM D36, EN 1427, and AASHTO T53.

- Ensures consistent heating and uniform bath temperature.

- Reliable and safer alternative to open-flame heating.

- Essential for asphalt quality control to predict high-temp performance. Here's the detailed content for the Azalab AZA 0933 Ring & Ball Apparatus (Electrical)

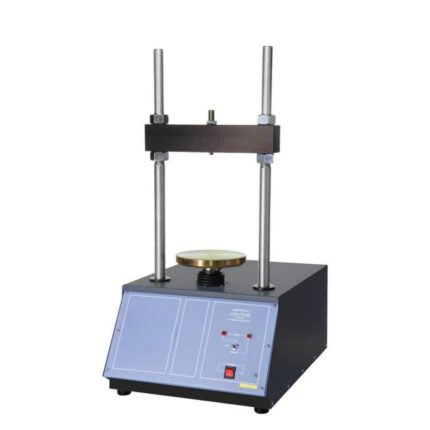

AZA 0938 STANDARD PENETROMETER

- AZA 0938 Standard Penetrometer: Reliable manual bitumen testing.

- Dial gauge with 0.1 mm resolution.

- Robust cast iron construction for durability.

- Conforms to ASTM D5, EN 1426, and other standards.

- Ideal for basic and consistent asphalt quality control.

- Manual operation for straightforward testing.

- Cost-effective solution for consistency determination

AZA 0942 HARDNESS TESTER FOR MASTIC ASPHALT

- AZA 0942 Hardness Tester: For mastic asphalt penetration testing.

- Determines consistency & workability of asphalt.

- Features precise dial gauge for accurate readings.

- Robust construction ensures stability and durability.

- Essential for quality control in road construction.

- Complies with relevant EN testing standards.

- Manual operation, reliable and easy to use

AZA 0943 STRIPPING VALUE APPARATUS

AZA 0946 CENTRIFUGE EXTRACTOR (MOTORISED)

- Motorised Operation: Eliminates manual effort, ensuring consistent and precise extraction.

- Accurate Bitumen Content: Determines bitumen percentage in bituminous mixtures with high precision.

- Variable Speed Control: Offers electronic control of bowl speed from 0 to 3600 RPM for optimized extraction.

- Safety Features: Includes automatic fast stop and robust construction for safe laboratory use.

- Standard Compliant: Meets ASTM D2172, AASHTO T-58, T-164 for reliable testing.

AZA 0949 SOLVENT RECOVERY UNIT

AZA 0953 MARSHALL STABILITY TEST APPARATUS

- Manual Operation: Reliable and cost-effective method for Marshall stability and flow testing.

- Precision Measurement: Features a proving ring and dial gauge for accurate readings.

- Standard Compliant: Adheres to essential asphalt mix design and testing standards.

- Durable Construction: Built for rigorous use in laboratory and field environments.

- Fundamental QC Tool: Indispensable for evaluating asphalt mix performance and optimizing designs

AZA 0957 REFRIGERATED DUCTILITY TEST

- Low-Temperature Ductility: Determines asphalt binder's ability to stretch at low temperatures.

- Simulates Cold Weather: Essential for predicting pavement cracking resistance in cold climates.

- Precise Temperature Control: Integrated refrigeration system for accurate testing temperatures.

- Automated Pulling: Controlled elongation for consistent and repeatable results.

- Standard Compliant: Meets ASTM D113 and AASHTO T51 standards

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items