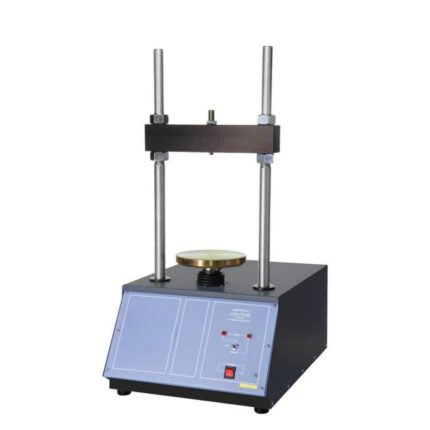

AZA 0937 DISTILLATION FOR CUT BACK BITUMEN

- AZA 0937 Distillation for Cut Back Bitumen: Determines volatile content.

- Includes 500 ml flask, condenser, 100 ml receiver.

- Electric hot plate with energy regulator for controlled heating.

- Essential for quality control of cut-back asphalt.

- Complies with ASTM D402, AASHTO T78, EN 13303.

- Ensures accurate assessment of bitumen curing properties.

- Robust construction for reliable lab use

Description

AZA 0937 Distillation for Cut Back Bitumen: Ensuring Quality and Performance with Azalab

The Azalab AZA 0937 Distillation Apparatus for Cut Back Bitumen is a crucial laboratory instrument designed for the accurate determination of the proportion of volatile diluents (fluxing agents or solvents) present in cut-back asphaltic materials. AZA 0937 Distillation for Cut Back Bitumen, Azalab, cut-back asphalt, volatile content, bitumen distillation, ASTM D402This test is vital for quality control in the production and application of cut-back bitumen, particularly in road construction, as it directly impacts the curing rate and the eventual performance characteristics of the asphalt pavement. By precisely measuring the volatile components, the AZA 0937 enables engineers and technicians to assess the material’s consistency, workability, and how quickly it will achieve its final viscosity after application.

Understanding Cut-Back Bitumen Properties with the AZA 0937 Distillation for Cut Back Bitumen

Cut-back bitumen is a blend of conventional bitumen with a volatile solvent to temporarily reduce its viscosity, allowing for easier handling, mixing, and application at lower temperatures. Once applied, the volatile solvent evaporates, leaving behind the original, harder bitumen binder. The distillation test using the AZA 0937 apparatus is the primary method to quantify the amount of this volatile component. The process involves heating a measured sample of the cut-back bitumen in a specific distillation flask at a controlled rate to a maximum temperature (typically 360°C). As the volatile components vaporize, they are cooled and condensed into a graduated receiver, allowing for precise measurement of the volume of distillate collected at various specified temperatures. This data is critical for classifying cut-back bitumens (e.g., rapid curing, medium curing, slow curing) and predicting their curing behavior in the field.

Comprehensive Components for Accurate Testing: The Azalab AZA 0937 Distillation for Cut Back Bitumen is a complete system, meticulously assembled to meet the requirements of relevant testing standards. A typical setup includes:

- Distillation Flask: A standard 500 ml distillation flask, made of heat-resistant borosilicate glass, designed with a side-arm for vapor transfer.

- Condenser Assembly: A water-cooled glass condenser tube with an inner tube that ensures efficient cooling and condensation of the volatile vapors back into liquid form.

- Receiving Cylinder (Crow Receiver): A precisely graduated glass cylinder (typically 100 ml capacity) for collecting and accurately measuring the volume of the distillate at specified temperature intervals.

- Heating Device: An electric hot plate or heating mantle with an energy regulator or digital temperature controller, providing uniform and controllable heat to the distillation flask.

- Distillation Shield & Support: A heavy-gauge metal shield, often lagged with asbestos or other insulating material, with a suitable opening for the flask. This shield minimizes heat loss and protects the flask from air currents, ensuring stable heating. The shield is supported on a platform with a chimney.

- Thermometers: Specific liquid-in-glass thermometers (e.g., ASTM 7C or ASTM 8C, covering temperature ranges like -2 to +300°C and -2 to +400°C) are used to monitor the vapor temperature at the flask neck and sometimes the liquid temperature.

- Stand and Clamps: Essential laboratory stands, clamps, and corks/adapters are provided to securely hold the distillation flask, condenser, and receiving cylinder in the correct configuration.

Adherence to International Standards: The Azalab AZA 0937 Distillation for Cut Back Bitumen is designed and manufactured to comply with key international standards for distillation of cut-back asphaltic products. These typically include:

- ASTM D402: Standard Test Method for Distillation of Cutback Asphalt.

- AASHTO T78: Standard Method of Test for Distillation of Cutback Asphaltic (Bituminous) Products.

- EN 13303: Bitumen and bituminous binders – Determination of the percentage of volatile components in cut-back and fluxed bituminous binders by distillation. Compliance with these standards ensures that tests performed using the AZA 0937 yield results that are globally recognized, comparable, and reliable for quality control, research, and regulatory purposes in the asphalt industry.

The Azalab Commitment to Quality and Support: Azalab is committed to providing high-quality, precise laboratory equipment that supports critical analysis in civil engineering and materials science. The AZA 0937 Distillation for Cut Back Bitumen embodies this commitment, offering a robust, accurate, and reliable solution for assessing the volatile content of cut-back asphalt. We understand the importance of precise material characterization for ensuring the safety, performance, and longevity of infrastructure. Our instruments are built to high standards, ensuring long-term performance and backed by comprehensive customer support.

Further Information and Resources: For detailed operational procedures, safety precautions related to handling volatile solvents, and specific test parameters, users should refer to the latest versions of applicable standards such as ASTM D402 or EN 13303. Additional technical information, user manuals, and details on compatible accessories can be found on the Azalab official website.

Specifications:

- Model: AZA 0937

- Test Method: Distillation of volatile diluents

- Sample Volume (Typical): 200 ml

- Distillation Flask: 500 ml capacity, heat-resistant borosilicate glass, side-arm type.

- Condenser: Water-cooled, glass, with an inner tube for efficient condensation.

- Receiving Cylinder (Crow Receiver): 100 ml capacity, graduated for precise volume measurement.

- Heating Device: Electric Hot Plate or Heating Mantle with Energy Regulator or Digital Temperature Controller (to control heating rate).

- Distillation Shield: Heavy gauge metal, lagged with insulation (e.g., asbestos/fire-proof), with cover and chimney.

- Thermometers (Not always included, usually specified by standard):

- ASTM 7C (-2°C to +300°C)

- ASTM 8C (-2°C to +400°C)

- Support Hardware: Stand, clamps, corks/adapters.

- Power Supply: Typically 230V, 50/60 Hz, Single Phase (confirm specific model).

- Standards Compliance: ASTM D402, AASHTO T78, EN 13303 (check specific model for full compliance details).

- Dimensions (Approx.): [Insert W x D x H, e.g., 300 x 300 x 600] mm (assembled apparatus).

- Weight (Approx.): [Insert Weight, e.g., 5-8] kg.

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What is the main purpose of the AZA 0937 Distillation apparatus?

- A: It is used to determine the percentage of volatile diluents (solvents) present in cut-back asphaltic materials by distilling them off at specific temperatures.

- Q: What is the typical sample volume used for the test?

- A: Standard tests typically use a 200 ml sample of the cut-back bitumen.

- Q: What standards does the AZA 0937 comply with?

- A: It is designed to comply with international standards like ASTM D402, AASHTO T78, and EN 13303.

- Q: Why is this test important for cut-back bitumen?

- A: It helps in classifying cut-back bitumen, predicting its curing rate, and ensuring its suitability for specific pavement applications.

- Q: What are the main components of the AZA 0937 apparatus?

- A: Key components include a distillation flask, condenser, receiving cylinder, electric heater, distillation shield, thermometers, and support stand.

Additional information

| Model |

AZA 0937 |

|---|---|

| Test Method |

Distillation of volatile diluents |

| Sample Volume (Typical) |

200 ml |

| Support Hardware |

Stand, clamps, corks/adapters. |

| Power Supply |

Typically 230V, 50/60 Hz, Single Phase |

| Weight (Approx.) |

[Insert Weight, e.g., 5-8] kg. |

Related products

AZA 0940 SEMI-AUTOMATIC PENETROMETER

- AZA 0940 Semi-Automatic Penetrometer: For bitumen consistency testing.

- Digital display with 0.01 mm resolution.

- Programmable electronic timer for automatic needle release.

- Meets ASTM D5 and EN 1426 standards.

- Ensures accurate & repeatable penetration results.

- Robust cast iron frame with fine leveling.

- Essential for asphalt quality control & grading

AZA 0943 STRIPPING VALUE APPARATUS

AZA 0945 CENTRIFUGE EXTRACTOR (MOTORISED)

AZA 0948 KINEMATIC VISCOMETER BATH

- Precise Temperature Control: Maintains highly stable and uniform temperatures for accurate viscosity measurements.

- High Visibility: Features toughened glass windows and illumination for clear observation of viscometers.

- Multi-Tube Capacity: Accommodates multiple glass capillary viscometers for simultaneous testing.

- Standard Compliant: Designed to meet rigorous international and Indian standards like ASTM D445 and IS 1206 (Part 3).

- Versatile Application: Ideal for bitumen, asphalt, petroleum products, lubricants, and other fluids.

AZA 0950 SAY BOLT VISCOMETER

- Empirical Viscosity: Measures flow time (efflux time) of liquids through a calibrated orifice.

- Dual Orifices: Typically equipped for both Saybolt Universal Viscosity (SUV) and Saybolt Furol Viscosity (SFV).

- Temperature Controlled: Features a precise heating system to maintain sample temperature during testing.

- Wide Application: Essential for testing lubricants, fuel oils, asphalt binders, and other petroleum products.

- Standard Compliant: Adheres to ASTM D88, AASHTO T72, and relevant IS standards for consistency.

AZA 0952 STANDARD TAR VISCOMETER

- Viscosity Determination: Measures the time taken for a specified volume of material to flow through a calibrated orifice.

- Target Materials: Ideal for cut-back bitumen, road oil, and other similar viscous materials.

- Precise Temperature Control: Features an electrically heated bath with dimmer stat for stable test temperatures.

- Application-Oriented: Helps assess flow properties crucial for road construction spraying and mixing.

- Quality Control Tool: Ensures consistency and suitability of bituminous binders for various applications

AZA 0953 MARSHALL STABILITY TEST APPARATUS

- Manual Operation: Reliable and cost-effective method for Marshall stability and flow testing.

- Precision Measurement: Features a proving ring and dial gauge for accurate readings.

- Standard Compliant: Adheres to essential asphalt mix design and testing standards.

- Durable Construction: Built for rigorous use in laboratory and field environments.

- Fundamental QC Tool: Indispensable for evaluating asphalt mix performance and optimizing designs

AZA 0960 TRAVELLING BEAM DEVICE

- Pavement Roughness Assessment: Accurately measures longitudinal unevenness of road surfaces.

- Riding Quality Indicator: Provides critical data for evaluating pavement serviceability and comfort.

- Robust & Portable: Durable construction, designed for efficient field measurements.

- Consistent Results: Ensures repeatable measurements for effective quality control.

- Essential for QC & Maintenance: Key tool for new construction validation and identifying rehabilitation needs

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items