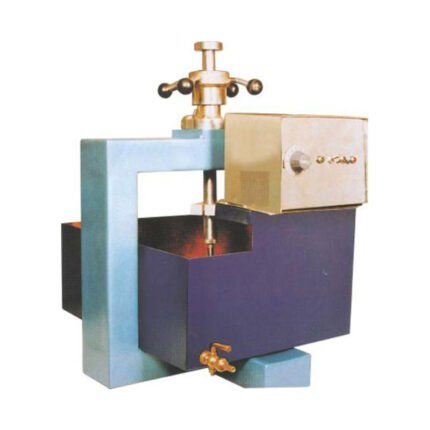

AZA 0941 REFLUX EXTRACTOR 4000 GMS

- AZA 0941 Reflux Extractor: For accurate bitumen content in asphalt.

- 4000 GMS capacity for larger samples.

- Efficient reflux method ensures thorough bitumen removal.

- Designed for safety and solvent recovery.

- Essential for quality control in road construction.

- Conforms to ASTM D2172 and similar standards.

- Durable construction for reliable lab performance

Description

AZA 0941 Reflux Extractor 4000 GMS: Accurate Bitumen Content Determination by Azalab

The Azalab AZA 0941 Reflux Extractor 4000 GMS is a sophisticated and highly efficient apparatus designed for the accurate determination of bitumen content in asphalt paving mixtures. Utilizing the precise reflux method, this extractor is an indispensable tool for quality control in civil engineering laboratories, road construction projects, and material testing facilities. Engineered to handle large samples of up to 4000 grams, the AZA 0941 provides a reliable and safe means to separate the bitumen binder from aggregate, ensuring that asphalt mixtures conform to critical design specifications and contribute to durable, high-performance pavements.

The Precision of the Reflux Method with the AZA 0941 Reflux Extractor 4000 GMS

The reflux extraction method is a cornerstone of bitumen content analysis due to its effectiveness and ability to handle larger samples. The AZA 0941 operates by continuously washing the asphalt sample with a solvent, which is then heated to vaporization. The solvent vapor condenses and drips back onto the sample, creating a continuous washing cycle that efficiently dissolves the bitumen. This method ensures thorough extraction, leaving the aggregate clean for subsequent grading and analysis. The precision offered by the reflux principle helps to minimize the loss of fine aggregate particles, leading to more accurate total aggregate weight and, consequently, a more precise determination of the bitumen content by difference.

Designed for Efficiency and Safety: Safety and operational efficiency are paramount in the design of the Azalab AZA 0941. The extractor typically comprises a heating mantle or hot plate, a main extraction vessel (often made of heat-resistant glass or metal), a condenser coil, and a collection system for the bitumen-solvent solution. The integral cooling system within the condenser ensures efficient condensation of the solvent vapor, preventing loss of solvent and maintaining a closed system. This not only makes the process more environmentally friendly but also significantly enhances safety by minimizing exposure to solvent fumes. The 4000-gram capacity makes it ideal for testing larger representative samples, reducing variability and improving the overall reliability of results, especially for large-scale construction projects.

Key Features for Optimal Performance: The AZA 0941 Reflux Extractor comes equipped with features that optimize its performance and ease of use. The heating element provides precise temperature control, ensuring the solvent vaporizes effectively without overheating. The robust construction of the glass components (if applicable) is designed to withstand the thermal stresses of the reflux process. A well-designed stand provides stability for the entire apparatus, while clear markings or scales on the collection vessel facilitate accurate measurement of the extracted solution. The unit is designed for easy assembly and disassembly, simplifying the cleaning process and maintenance, thereby extending the lifespan of the equipment. Furthermore, the design typically allows for easy observation of the extraction process, enabling operators to monitor the clarity of the dripping solvent and determine when the extraction is complete.

Adherence to Industry Standards: The Azalab AZA 0941 Reflux Extractor is manufactured to conform to relevant international and national testing standards for bitumen extraction, such as ASTM D2172 (Standard Test Methods for Quantitative Extraction of Bitumen from Bituminous Paving Mixtures) or similar equivalent standards. Adherence to these standards ensures that the test results obtained using the AZA 0941 are consistent, reproducible, and accepted worldwide. This compliance is crucial for quality assurance, research, and for fulfilling contractual obligations in road construction and civil engineering projects.

The Azalab Commitment to Quality and Support: Azalab is committed to delivering high-quality, reliable laboratory equipment that empowers accurate material testing. The AZA 0941 Reflux Extractor 4000 GMS exemplifies this commitment, offering a robust, efficient, and safe solution for bitumen content determination. We understand the critical role of precise measurements in ensuring the integrity and longevity of infrastructure. Our dedication extends to providing comprehensive customer support and resources to ensure optimal performance and longevity of our equipment.

Further Information and Resources: For detailed operational procedures, solvent recommendations, and safety guidelines, please refer to the specific standard methods like ASTM D2172. You can also find additional technical information, user manuals, and details on compatible accessories by visiting the Azalab official website.

Specifications:

- Model: AZA 0941

- Method: Reflux Extraction

- Sample Capacity: Up to 4000 grams (4 kg) of asphalt mixture

- Components:

- Heating Mantle/Hot Plate (controlled heating)

- Extraction Vessel (typically heat-resistant glass or metal, appropriate volume for 4000g sample)

- Condenser (glass coil, highly efficient cooling for solvent recovery)

- Solvent Collection Flask/Beaker

- Supporting Stand

- Material (Vessel/Condenser): High-quality Borosilicate Glass or Stainless Steel (depending on specific model variation)

- Power Supply (for heating element): [e.g., 220-240V, 50/60 Hz, single phase]

- Safety Features: Closed system to minimize solvent evaporation, robust construction

- Dimensions: Approx. [Insert W x D x H, e.g., 400 x 300 x 700] mm (varies based on specific design)

- Weight: Approx. [Insert Weight, e.g., 15-25] kg

- Standards: Conforms to relevant standards like ASTM D2172 (check specific model for full compliance details)

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What is the maximum sample capacity of the AZA 0941 Reflux Extractor?

- A: The AZA 0941 is designed to handle asphalt samples up to 4000 grams.

- Q: What kind of solvents are typically used with this extractor?

- A: Common solvents include trichloroethylene, methylene chloride, or other approved solvents for bitumen extraction. Always consult safety data sheets and local regulations.

- Q: How does the reflux method work?

- A: The solvent continuously washes the sample, vaporizes, condenses, and drips back, creating a continuous washing cycle to dissolve bitumen.

- Q: Does it conform to any specific testing standards?

- A: Yes, it is designed to conform to relevant standards such as ASTM D2172 for quantitative extraction of bitumen.

- Q: What are the benefits of using a reflux extractor over a centrifuge?

- A: Reflux extractors can handle larger sample sizes and often provide a more thorough washing of the aggregate, which is beneficial for accurate bitumen content determination.

Additional information

| Model |

AZA 0941 |

|---|---|

| Method |

Reflux Extraction |

| Sample Capacity |

Up to 4000 grams (4 kg) of asphalt mixture |

| Weight |

Approx. [Insert Weight, e.g., 15-25] kg |

| Power Supply (for heating element) |

[e.g., 220-240V, 50/60 Hz, single phase] |

| Safety Features |

Closed system to minimize solvent evaporation, robust construction |

Related products

AZA 0933 RING AND BALL APPARATUS (ELECTRICAL)

- AZA 0933 Ring & Ball Apparatus (Electrical): For bitumen softening point.

- Features electrically controlled 5°C/min heating rate.

- Digital temperature display with integrated magnetic stirrer.

- Complies with ASTM D36, EN 1427, and AASHTO T53.

- Ensures consistent heating and uniform bath temperature.

- Reliable and safer alternative to open-flame heating.

- Essential for asphalt quality control to predict high-temp performance. Here's the detailed content for the Azalab AZA 0933 Ring & Ball Apparatus (Electrical)

AZA 0938 STANDARD PENETROMETER

- AZA 0938 Standard Penetrometer: Reliable manual bitumen testing.

- Dial gauge with 0.1 mm resolution.

- Robust cast iron construction for durability.

- Conforms to ASTM D5, EN 1426, and other standards.

- Ideal for basic and consistent asphalt quality control.

- Manual operation for straightforward testing.

- Cost-effective solution for consistency determination

AZA 0942 HARDNESS TESTER FOR MASTIC ASPHALT

- AZA 0942 Hardness Tester: For mastic asphalt penetration testing.

- Determines consistency & workability of asphalt.

- Features precise dial gauge for accurate readings.

- Robust construction ensures stability and durability.

- Essential for quality control in road construction.

- Complies with relevant EN testing standards.

- Manual operation, reliable and easy to use

AZA 0944 CENTRIFUGE EXTRACTOR (HAND OPERATED)

- AZA 0944 Hand Centrifuge: For accurate bitumen content determination.

- Manual hand-crank operation; no external power needed.

- Durable cast aluminum construction for longevity.

- Ideal for asphalt and road paving mixture analysis.

- Removable aluminum bowl for easy sample handling & cleaning.

- Essential tool for civil engineering and material testing labs.

- Ensures quality control in road construction projects

AZA 0946 CENTRIFUGE EXTRACTOR (MOTORISED)

- Motorised Operation: Eliminates manual effort, ensuring consistent and precise extraction.

- Accurate Bitumen Content: Determines bitumen percentage in bituminous mixtures with high precision.

- Variable Speed Control: Offers electronic control of bowl speed from 0 to 3600 RPM for optimized extraction.

- Safety Features: Includes automatic fast stop and robust construction for safe laboratory use.

- Standard Compliant: Meets ASTM D2172, AASHTO T-58, T-164 for reliable testing.

AZA 0950 SAY BOLT VISCOMETER

- Empirical Viscosity: Measures flow time (efflux time) of liquids through a calibrated orifice.

- Dual Orifices: Typically equipped for both Saybolt Universal Viscosity (SUV) and Saybolt Furol Viscosity (SFV).

- Temperature Controlled: Features a precise heating system to maintain sample temperature during testing.

- Wide Application: Essential for testing lubricants, fuel oils, asphalt binders, and other petroleum products.

- Standard Compliant: Adheres to ASTM D88, AASHTO T72, and relevant IS standards for consistency.

AZA 0951 SAYBOLT TWO-TUBE DIGITAL VISCOMETER

AZA 0960 TRAVELLING BEAM DEVICE

- Pavement Roughness Assessment: Accurately measures longitudinal unevenness of road surfaces.

- Riding Quality Indicator: Provides critical data for evaluating pavement serviceability and comfort.

- Robust & Portable: Durable construction, designed for efficient field measurements.

- Consistent Results: Ensures repeatable measurements for effective quality control.

- Essential for QC & Maintenance: Key tool for new construction validation and identifying rehabilitation needs

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items