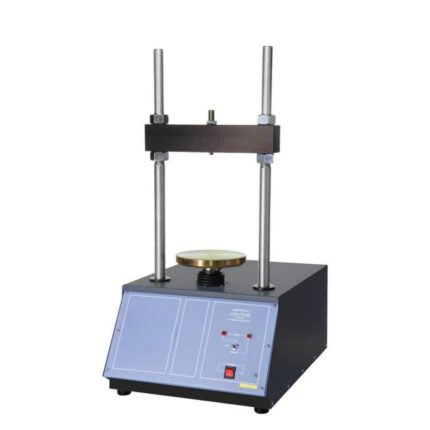

AZA 0944 CENTRIFUGE EXTRACTOR (HAND OPERATED)

- AZA 0944 Hand Centrifuge: For accurate bitumen content determination.

- Manual hand-crank operation; no external power needed.

- Durable cast aluminum construction for longevity.

- Ideal for asphalt and road paving mixture analysis.

- Removable aluminum bowl for easy sample handling & cleaning.

- Essential tool for civil engineering and material testing labs.

- Ensures quality control in road construction projects

Description

AZA 0944 Centrifuge Extractor (Hand Operated): Precision Bitumen Content Analysis by Azalab

Introducing the Azalab AZA 0944 Centrifuge Extractor, a robust and reliable hand-operated instrument meticulously designed for the accurate determination of bitumen content in asphalt and road paving mixtures. This essential piece of laboratory equipment provides a cost-effective and efficient solution for engineers, technicians, and quality control personnel in civil engineering, road construction, and material testing laboratories. Engineered for durability and ease of use, AZA 0944 Hand Centrifuge Extractor, Azalab, bitumen content, asphalt testing, hand operated centrifuge the AZA 0944 ensures consistent and precise results, crucial for maintaining the quality and integrity of asphalt pavements.

Unmatched Precision for Material Analysis: The core function of the AZA 0944 Centrifuge Extractor is to separate bitumen binder from aggregate material using centrifugal force. This process is fundamental in quality control procedures for asphalt mixtures, allowing for the accurate calculation of bitumen content – a critical parameter that directly influences the performance, durability, and workability of asphalt. By providing a clear separation, the AZA 0944 helps ensure that the asphalt mix adheres to design specifications, preventing issues such as premature cracking, rutting, or stripping in road surfaces AZA 0944 Hand Centrifuge Extractor, Azalab, bitumen content, asphalt testing, hand operated centrifuge. Its efficient extraction capability allows for thorough washing of the aggregate, leaving it free from bitumen residue for subsequent analysis.

Designed for Durability and Field Utility: Constructed from high-quality, corrosion-resistant materials, the AZA 0944 is built to withstand the demanding conditions of laboratory environments and even field testing. Its sturdy cast aluminum body ensures long-term stability and reliability, minimizing vibrations during operation for consistent results. The robust hand crank mechanism is designed for smooth, effortless rotation, making it simple for operators to achieve the necessary rotational speeds without undue physical exertion. This manual operation not only makes it ideal for locations without immediate access to power but also ensures its longevity due to fewer complex electronic components susceptible to failure.

Key Features for Efficient Operation: The AZA 0944 Centrifuge Extractor comes equipped with several features that enhance its utility and user experience. It typically includes a removable aluminum bowl, designed for easy loading of the asphalt sample and convenient cleaning after each test. The precisely machined shaft and bearing system ensure smooth, high-speed rotation, maximizing the separation efficiency. A tight-fitting lid minimizes solvent evaporation and ensures safe operation by containing the sample during extraction. For effective filtration, it often comes with a set of filter papers, which are crucial for retaining fine aggregate particles while allowing the bitumen-solvent solution to pass through .

Simple Operation, Reliable Results: Operating the AZA 0944 is straightforward. A weighed sample of the asphalt mixture is placed into the extraction bowl, and a suitable solvent (such as trichloroethylene or methylene chloride, adhering to safety guidelines) is added. The bowl is then covered, and the hand crank is rotated steadily to generate centrifugal force. This force separates the bitumen-solvent solution from the aggregate, with the solution being collected in a pan beneath the extractor. The process is repeated with fresh solvent until the aggregate is clean. The extracted aggregate can then be weighed and sieved for gradation analysis, while the bitumen content is determined by weight difference. This simple, repeatable procedure makes it an invaluable tool for routine quality checks.

The Azalab Commitment to Quality: At Azalab, we are dedicated to providing high-quality, reliable laboratory equipment that meets the stringent demands of material testing. The AZA 0944 Centrifuge Extractor is a testament to our commitment, offering a practical, durable, and accurate solution for bitumen content determination. We understand the importance of precise measurements in civil engineering projects, and this hand-operated extractor is engineered to deliver them consistently.

Further Information and Resources: For detailed operational procedures and safety guidelines related to solvent use, please refer to relevant ASTM standards such as ASTM D2172 (Standard Test Methods for Quantitative Extraction of Bitumen from Bituminous Paving Mixtures) or similar international standards. For maintenance tips and to explore our full range of material testing equipment, visit the Azalab official website.

Specifications:

- Operation: Hand Operated (Manual Crank)

- Material: Heavy-duty Cast Aluminum Body

- Bowl Material: Aluminum (Removable)

- Capacity: Typically [Insert Capacity, e.g., 1000g / 1500g / 3000g] asphalt sample

- Speed: Achieves high rotational speeds for efficient separation (manual operation)

- Filter System: Designed for use with standard circular filter papers

- Collection: Integrated pan for solvent collection

- Dimensions: Approx. [Insert W x D x H, e.g., 300 x 300 x 450] mm (varies slightly by model)

- Weight: Approx. [Insert Weight, e.g., 10-15] kg

- Standards: Conforms to relevant industry standards such as ASTM D2172 (check specific model for full compliance details)

FREQUENTLY ASKED QUESTIONS (FAQ):

- Q: What type of samples can be tested with the AZA 0944?

- A: The AZA 0944 is primarily designed for determining bitumen content in asphalt and road paving mixtures.

- Q: What solvents are typically used with this extractor?

- A: Common solvents include trichloroethylene, methylene chloride, or other approved solvents for bitumen extraction. Always adhere to safety data sheets and local regulations for solvent handling.

- Q: Is the AZA 0944 suitable for field use?

- A: Yes, its hand-operated design and robust construction make it highly suitable for field quality control where electricity may not be readily available.

- Q: How often should the filter papers be replaced?

- A: Filter papers should be replaced after each extraction to ensure accurate results and prevent contamination.

- Q: What is the capacity of the extraction bowl?

- A: The capacity of the extraction bowl is typically [Insert Capacity, e.g., 1000g or 1500g] of asphalt mixture, depending on the specific model variation.

Additional information

| Operation |

Hand Operated (Manual Crank) |

|---|---|

| Material |

Heavy-duty Cast Aluminum Body |

| Bowl Material |

Aluminum (Removable) |

| Weight |

Approx. [Insert Weight, e.g., 10-15] kg |

| Filter System |

Designed for use with standard circular filter papers |

| Collection |

Integrated pan for solvent collection |

Related products

AZA 0932 RING AND BALL APPARATUS

- AZA 0932 Ring and Ball Apparatus: Manual softening point tester for bitumen.

- Robust steel construction with clear glass beaker.

- Includes standard brass rings, steel balls, and hand stirrer.

- Complies with IS 1205, ASTM D36, EN 1427, IP 58/63.

- Essential for quality control of bitumen in hot climates.

- Cost-effective solution for reliable softening point determination.

- Requires external heat source and thermometers (sold separately).

AZA 0933 RING AND BALL APPARATUS (ELECTRICAL)

- AZA 0933 Ring & Ball Apparatus (Electrical): For bitumen softening point.

- Features electrically controlled 5°C/min heating rate.

- Digital temperature display with integrated magnetic stirrer.

- Complies with ASTM D36, EN 1427, and AASHTO T53.

- Ensures consistent heating and uniform bath temperature.

- Reliable and safer alternative to open-flame heating.

- Essential for asphalt quality control to predict high-temp performance. Here's the detailed content for the Azalab AZA 0933 Ring & Ball Apparatus (Electrical)

AZA 0935 FRAASS BREAKING POINT APPARATUS

- AZA 0935 Fraass Breaking Point Apparatus: Determines bitumen's brittle temperature.

- Critical for assessing low-temperature asphalt performance.

- Includes precise mechanical flexing device and cooling bath.

- Complies with EN 12593 international standard.

- Ensures selection of suitable bitumen for cold climates.

- Robust construction for reliable laboratory use.

- Measures temperature at which bitumen film cracks

AZA 0936 WATER IN BITUMINOUS MATERIAL (DEAN-STARK)

- AZA 0936 Water in Bituminous Material Dean-Stark: Accurate water content testing.

- Utilizes the reliable Dean-Stark distillation method.

- Includes distillation flask, graduated trap, and reflux condenser.

- Essential for quality control of asphalt, bitumen, and road materials.

- Complies with ASTM D95, EN 1428, and AASHTO T55 standards.

- Ensures material quality and pavement durability.

- Robust borosilicate glass components for lab use

AZA 0941 REFLUX EXTRACTOR 4000 GMS

- AZA 0941 Reflux Extractor: For accurate bitumen content in asphalt.

- 4000 GMS capacity for larger samples.

- Efficient reflux method ensures thorough bitumen removal.

- Designed for safety and solvent recovery.

- Essential for quality control in road construction.

- Conforms to ASTM D2172 and similar standards.

- Durable construction for reliable lab performance

AZA 0951 SAYBOLT TWO-TUBE DIGITAL VISCOMETER

AZA 0953 MARSHALL STABILITY TEST APPARATUS

- Manual Operation: Reliable and cost-effective method for Marshall stability and flow testing.

- Precision Measurement: Features a proving ring and dial gauge for accurate readings.

- Standard Compliant: Adheres to essential asphalt mix design and testing standards.

- Durable Construction: Built for rigorous use in laboratory and field environments.

- Fundamental QC Tool: Indispensable for evaluating asphalt mix performance and optimizing designs

AZA 0959 STRAIGHT EDGE (3 Meters)

- Pavement Regularity Check: Precisely identifies undulations and irregularities on road surfaces.

- Optimal Length: 3-meter length covers sufficient road sections for effective assessment.

- Lightweight & Durable: Constructed from high-grade aluminum for easy handling and long life.

- Essential for QC: Key tool for ensuring riding comfort, safety, and proper drainage.

- Standard Compliant: Adheres to critical national road construction quality standards

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items