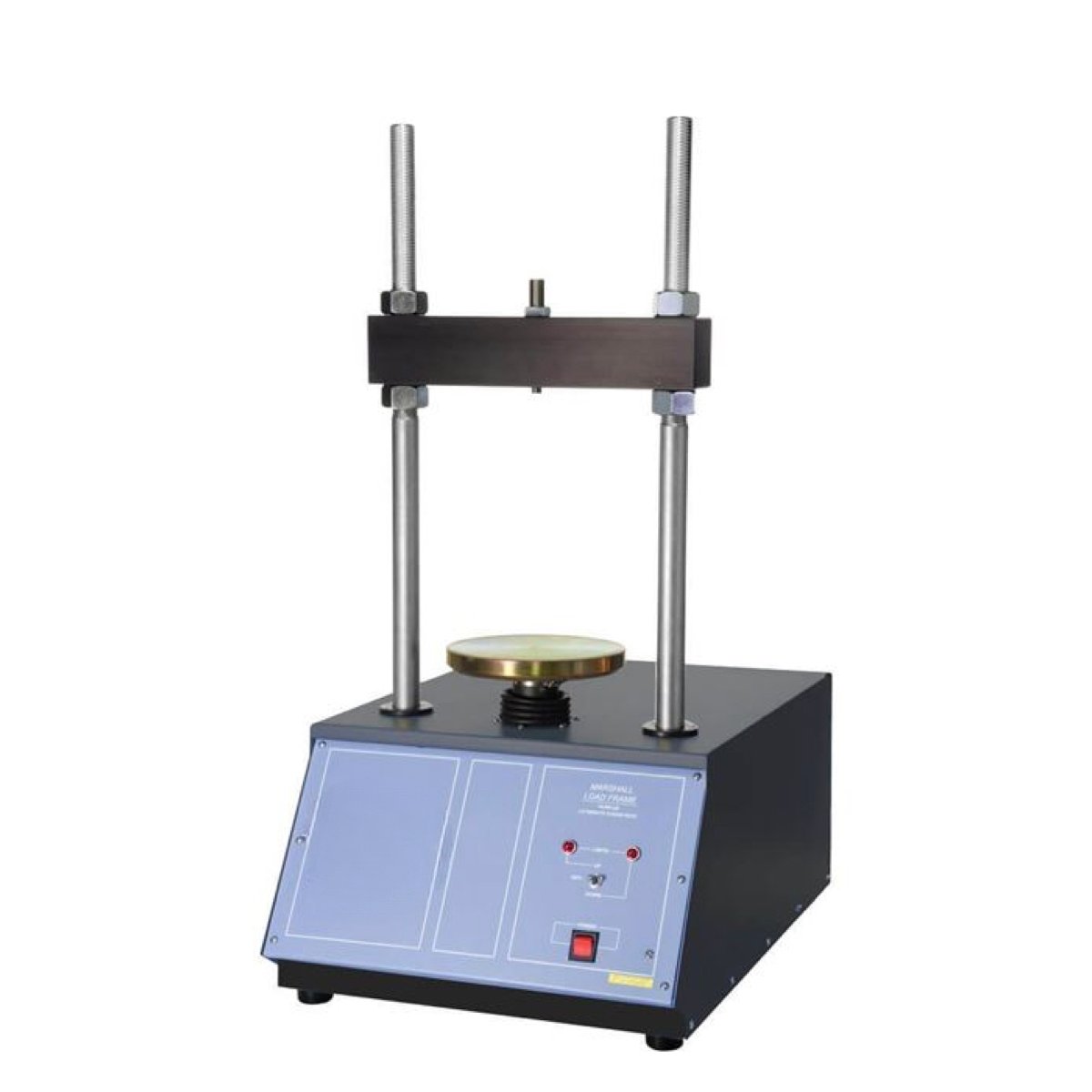

AZA 0953 MARSHALL STABILITY TEST APPARATUS

- Manual Operation: Reliable and cost-effective method for Marshall stability and flow testing.

- Precision Measurement: Features a proving ring and dial gauge for accurate readings.

- Standard Compliant: Adheres to essential asphalt mix design and testing standards.

- Durable Construction: Built for rigorous use in laboratory and field environments.

- Fundamental QC Tool: Indispensable for evaluating asphalt mix performance and optimizing designs

Description

The AZA 0953 Marshall Stability Test Apparatus from AZALAB is a fundamental and widely utilized instrument in civil engineering laboratories for evaluating the performance characteristics of compacted bituminous mixtures. It forms the core of the Marshall Mix Design method, a globally recognized standard for designing and controlling the quality of asphalt concrete pavements. This apparatus precisely measures two critical properties of an asphalt mix: Marshall Stability and Marshall Flow, which collectively indicate the mix’s resistance to permanent deformation under traffic loads and its ability to accommodate stress without cracking.

At the heart of the AZA 0953’s functionality is its robust load frame and precise measurement components. A standard cylindrical Marshall specimen, pre-conditioned to a specific test temperature (commonly $60^\\circ\\text{C}$ in a water bath), is placed in a semi-circular breaking head. A hand-operated or motorized loading ram then applies a continuous compressive load to the specimen at a constant rate, typically 50.8 mm/min (2.0 inches/min). The key measurements are obtained through:

- Proving Ring: This calibrated elastic ring, fitted with a sensitive dial gauge, measures the maximum load applied to the specimen before it fails. This maximum load is the Marshall Stability value, indicating the mix’s strength.

- Flow Meter (Dial Gauge): A separate dial gauge, or often the same gauge with a distinct setup, measures the vertical deformation of the specimen from the initial load application to the point of maximum load. This deformation is the Marshall Flow value, representing the mix’s flexibility.

While manually operated in terms of data recording, the AZA 0953 is designed for high precision and reliability. Its construction ensures that the loading rate is maintained consistently, critical for obtaining reproducible results. This apparatus adheres strictly to established standards such as IS 2720 (Part 10): Methods of Test for Soils: Determination of Stability and Flow of Bituminous Mixes (Marshall Test), making it ideal for quality control in road projects across India.

Ensuring Pavement Performance with the AZA 0953 Marshall Tester

The AZA 0953 Marshall Stability Test Apparatus is built for durability and long-term performance in demanding laboratory environments. It features a sturdy, high-strength load frame that provides a rigid testing platform, ensuring accurate transmission of force to the specimen. The loading ram is designed for smooth operation, while the proving ring and flow dial gauge are precision instruments calibrated to provide accurate readings. The breaking head is designed to perfectly accommodate standard 101.6 mm (4-inch) diameter Marshall specimens. Its relatively simple operation and robust construction make it a cost-effective solution for laboratories where automated systems may not be required or feasible.

The significance of the data obtained from the AZA 0953 is profound for asphalt pavement engineering:

- Optimum Mix Design: Marshall Stability and Flow are fundamental criteria used to determine the optimum bitumen content for an asphalt mix, balancing strength with sufficient flexibility to prevent cracking.

- Resistance to Deformation: High stability values generally correlate with better resistance to permanent deformation (rutting) under heavy traffic loads and high temperatures.

- Flexibility and Durability: Appropriate flow values ensure that the pavement can accommodate minor deflections without brittle failure, enhancing its resistance to fatigue and thermal cracking.

- Quality Control & Acceptance: Essential for verifying that asphalt mixtures produced in plants meet the design specifications, serving as a critical quality assurance tool for highway agencies and contractors. For detailed guidelines on asphalt mix design and performance, the Ministry of Road Transport & Highways (MoRTH) Specifications for Road and Bridge Works and publications by the Indian Roads Congress (IRC) are authoritative sources in India.

Operating the AZA 0953 involves pre-conditioning the asphalt specimen, placing it in the breaking head, and then manually applying the load via a handwheel or a motor-driven mechanism. The operator carefully observes the dial gauges to record the maximum load and corresponding flow. Regular calibration of the proving ring and flow dial gauge, along with routine cleaning, is essential to maintain the apparatus’s accuracy and reliability.

In conclusion, the AZA 0953 Marshall Stability Test Apparatus from AZALAB is an indispensable, reliable, and economical tool for asphalt testing laboratories. Its ability to accurately determine Marshall stability and flow makes it a vital component for engineers involved in designing, evaluating, and ensuring the quality of durable and high-performing asphalt pavements, contributing significantly to robust infrastructure development across India.

Specifications

- Model Number: AZA 0953

- Test Method: Marshall Stability and Flow Test (Manual/Semi-Automatic)

- Loading Capacity: Typically up to 25 kN or 50 kN (2500 kgf or 5000 kgf), measured by a proving ring.

- Loading Rate: Hand-operated or motor-driven to achieve a standard rate of 50.8 mm/min (2.0 inches/min).

- Load Measurement:

- Proving Ring: Capacities typically 25 kN or 50 kN, fitted with a dial gauge (e.g., 0.002 mm least count).

- Flow Measurement:

- Flow Meter: Dial Gauge (e.g., 0-25 mm range, 0.01 mm least count) to measure deformation.

- Specimen Size: Suitable for standard Marshall specimens (101.6 mm / 4-inch diameter).

- Breaking Head: Steel, with semi-circular segments to hold the specimen.

- Temperature Conditioning: Requires an external water bath or air oven (e.g., AZA 0958 Marshall Water Bath) to condition specimens to $60^\\circ\\text{C}$ (or other specified temperature).

- Load Frame: Robust steel frame for stability.

- Standard Compliance: Conforms to IS 2720 (Part 10), ASTM D1559 (related, but D6927 is automatic), AASHTO T245 (related, but T283 is automatic), and other relevant standards.

- Power Supply: 230V AC, 50 Hz, Single Phase (for motorized versions).

- Dimensions & Weight: Varies based on specific design; built for laboratory use.

- Included Accessories: Proving Ring, Flow Meter, Marshall Breaking Head, User Manual.

FREQUENTLY ASKED QUESTIONS (FAQ)

Q1: What is the primary function of the AZA 0953 Marshall Stability Test Apparatus? A1: The AZA 0953 Marshall Stability Test Apparatus is used to determine the Marshall stability (resistance to deformation) and Marshall flow (deformation at failure) of compacted bituminous mixtures, which are crucial for asphalt pavement design.

Q2: How does the AZA 0953 measure stability and flow? A2: It measures stability using a proving ring that indicates the maximum load sustained by the specimen. Flow is measured by a dial gauge that records the vertical deformation of the specimen at the point of maximum load.

Q3: What are the main differences between the AZA 0953 (manual) and an automatic Marshall Tester (like AZA 0954)? A3: The AZA 0953 requires manual recording of load and flow readings (though loading can be motorized), while automatic versions use load cells and LVDTs for digital data acquisition, typically offering more precision and automation in data logging and analysis. The AZA 0953 is generally more cost-effective.

Q4: What Indian standards does this Marshall Stability Test Apparatus comply with? A4: The AZA 0953 is designed to comply with IS 2720 (Part 10), which specifically outlines the Marshall Test method for bituminous mixes in India. It also aligns with principles of ASTM D1559/D6927 and AASHTO T245/T283.

Q5: Is an external temperature conditioning bath required for this apparatus? A5: Yes, specimens must be conditioned to the specified test temperature (e.g., $60^\\circ\\text{C}$) in a separate temperature-controlled water bath or air oven (like the AZA 0958 Marshall Water Bath) before being placed in the Marshall Stability Test Apparatus.

Q6: How does using the AZA 0953 contribute to the quality of Indian roads? A6: By providing reliable data on the stability and flow of asphalt mixes, the Marshall Stability Test Apparatus enables engineers to design and verify road construction materials that are optimized for local traffic conditions and climate, leading to more durable, rut-resistant, and long-lasting roads across India.

Additional information

| Model Number |

AZA 0953 |

|---|---|

| Test Method |

Marshall Stability and Flow Test (Manual/Semi-Automatic) |

| Specimen Size |

Suitable for standard Marshall specimens (101.6 mm / 4-inch diameter). |

| Breaking Head |

Steel, with semi-circular segments to hold the specimen. |

| Load Frame |

Robust steel frame for stability. |

| Power Supply |

230V AC, 50 Hz, Single Phase |

Related products

AZA 0936 WATER IN BITUMINOUS MATERIAL (DEAN-STARK)

- AZA 0936 Water in Bituminous Material Dean-Stark: Accurate water content testing.

- Utilizes the reliable Dean-Stark distillation method.

- Includes distillation flask, graduated trap, and reflux condenser.

- Essential for quality control of asphalt, bitumen, and road materials.

- Complies with ASTM D95, EN 1428, and AASHTO T55 standards.

- Ensures material quality and pavement durability.

- Robust borosilicate glass components for lab use

AZA 0938 STANDARD PENETROMETER

- AZA 0938 Standard Penetrometer: Reliable manual bitumen testing.

- Dial gauge with 0.1 mm resolution.

- Robust cast iron construction for durability.

- Conforms to ASTM D5, EN 1426, and other standards.

- Ideal for basic and consistent asphalt quality control.

- Manual operation for straightforward testing.

- Cost-effective solution for consistency determination

AZA 0944 CENTRIFUGE EXTRACTOR (HAND OPERATED)

- AZA 0944 Hand Centrifuge: For accurate bitumen content determination.

- Manual hand-crank operation; no external power needed.

- Durable cast aluminum construction for longevity.

- Ideal for asphalt and road paving mixture analysis.

- Removable aluminum bowl for easy sample handling & cleaning.

- Essential tool for civil engineering and material testing labs.

- Ensures quality control in road construction projects

AZA 0948 KINEMATIC VISCOMETER BATH

- Precise Temperature Control: Maintains highly stable and uniform temperatures for accurate viscosity measurements.

- High Visibility: Features toughened glass windows and illumination for clear observation of viscometers.

- Multi-Tube Capacity: Accommodates multiple glass capillary viscometers for simultaneous testing.

- Standard Compliant: Designed to meet rigorous international and Indian standards like ASTM D445 and IS 1206 (Part 3).

- Versatile Application: Ideal for bitumen, asphalt, petroleum products, lubricants, and other fluids.

AZA 0951 SAYBOLT TWO-TUBE DIGITAL VISCOMETER

AZA 0952 STANDARD TAR VISCOMETER

- Viscosity Determination: Measures the time taken for a specified volume of material to flow through a calibrated orifice.

- Target Materials: Ideal for cut-back bitumen, road oil, and other similar viscous materials.

- Precise Temperature Control: Features an electrically heated bath with dimmer stat for stable test temperatures.

- Application-Oriented: Helps assess flow properties crucial for road construction spraying and mixing.

- Quality Control Tool: Ensures consistency and suitability of bituminous binders for various applications

AZA 0958 ELASTIC RECOVERY MOULD

AZA 0960 TRAVELLING BEAM DEVICE

- Pavement Roughness Assessment: Accurately measures longitudinal unevenness of road surfaces.

- Riding Quality Indicator: Provides critical data for evaluating pavement serviceability and comfort.

- Robust & Portable: Durable construction, designed for efficient field measurements.

- Consistent Results: Ensures repeatable measurements for effective quality control.

- Essential for QC & Maintenance: Key tool for new construction validation and identifying rehabilitation needs

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items