Ball Release for Impact Resistance Tester(AZA 1295)

- Ensures accurate and repeatable ball drop tests

- Precision ball release mechanism for lab use

- Ideal for impact resistance testing of plastics, glass, coatings

- Supports various ball sizes and weights

- Durable construction for long-term reliability

- Compatible with ASTM and ISO impact test standards

- Simple to install and operate

Description

Ball Release for Impact Resistance Tester is a critical lab tool engineered for accurate and repeatable drop testing of materials to determine their impact strength. Whether in R&D labs, quality control environments, or educational institutions, this device ensures consistent testing for materials like plastic, glass, ceramics, packaging, and flexible films.

The apparatus is designed to release a weighted ball from a specific height using a manual trigger or magnetic mechanism. This standardized drop simulates real-world impacts, allowing manufacturers and researchers to assess whether materials can withstand sudden forces or stress without cracking, breaking, or deforming.Ball Release for Impact Resistance Tester, impact tester ball, drop test ball.Ball Release for Impact Resistance Tester provides controlled, accurate ball drop testing for material durability in labs and industrial QA environments..

🧪 Applications Across Industries

-

Plastic & Polymer Testing – Validate toughness of molded or extruded products

-

Glass & Ceramic Products – Assess break resistance for safety compliance

-

Paints & Coatings – Test adhesion and flexibility under impact

-

Flexible Films – Evaluate puncture resistance in packaging materials

-

Consumer Goods – Verify durability of protective casings and screens

-

Construction Materials – Simulate impact from falling debris or usage pressure

🔗 Read more about drop weight impact test standards here: www.astm.org/d5420

⚙️ Features & Technical Advantages

-

Precision Ball Drop – The release system ensures the ball drops at the exact same angle and speed every time.

-

Height Adjustability – Works with drop towers or custom frames for up to 2 meters in height.

-

Multiple Ball Configurations – Choose from steel, rubber, or tungsten carbide balls depending on the test requirement.

-

Quick Setup & Use – Designed for plug-and-play installation on standard drop equipment.

-

Low Maintenance – Built from high-grade stainless steel with corrosion-resistant components.

-

International Compatibility – Fully compliant with ASTM D5420, ISO 6603-2, and other global standards.

🔗 For ISO impact test guidance, refer to: www.iso.org/standard/60908.html

This product is ideal for organizations that require strict quality assurance protocols. It helps eliminate human error in drop testing and provides consistent results over time. Moreover, its versatility means it can be used in both manual setups or integrated into automated systems.

📦 What’s Included in the Package?

-

Precision Ball Release Mechanism

-

Adjustable Mounting Bracket

-

Choice of Ball (Steel or Rubber)

-

Setup & Calibration Guide

-

Maintenance Toolkit (Optional)

Optional add-ons: high-speed camera integration, drop towers, digital sensors, and automated release mechanisms.

Specifications

| Feature | Specification |

|---|---|

| Release Mechanism | Manual trigger or magnetic drop |

| Construction Material | Stainless Steel, Aluminum |

| Ball Compatibility | 10 mm to 50 mm, various materials |

| Drop Height | Adjustable up to 2000 mm |

| Ball Types | Steel, Tungsten Carbide, Rubber |

| Mount Compatibility | Universal vertical or custom frame |

| Compliance Standards | ASTM D5420, ISO 6603-2 |

| Calibration Frequency | Every 6–12 months or 500 test cycles |

| Operating Environment | Lab, Industrial, Quality Control |

FREQUENTLY ASKED QUESTIONS (FAQ):

Q1: What is the purpose of this tester?

A1: It simulates impact on materials by dropping a standardized ball from a fixed height to assess durability and resistance.

Q2: Can I use different types of balls?

A2: Yes. You can use steel, rubber, or tungsten carbide balls in multiple sizes based on the test requirements.

Q3: Is this device compatible with existing drop towers?

A3: Yes. The universal mount fits most vertical towers and lab frames.

Q4: How accurate is the release mechanism?

A4: The mechanism ensures consistent and precise drops, removing human variability.

Q5: Does it require frequent calibration?

A5: Calibration every 6–12 months is sufficient for standard use. More frequent checks are advised for high-volume testing.

Additional information

| Material |

Stainless Steel / Hardened Aluminum |

|---|---|

| Compatible Ball Sizes |

10 mm to 50 mm |

| Drop Height Range |

Adjustable (up to 2000 mm) |

| Release Type |

Manual trigger / Magnetic (optional) |

- Automatic COR Calculation: Real-time coefficient computation based on rebound time or height.

- Precision Release Mechanism: Electromagnet-controlled ball drop ensures consistent center-hit.

- User-Friendly Interface: Digital indicator with backlit screen.

- Rigid Frame Construction: Prevents unwanted tile movement for repeatable testing.

- Test Mold Provided: Includes 75 x 75 mm mold cube for accurate tile placement.

Compliance:

- EN ISO 10545‑5 – Ceramic tiles: Determination of impact resistance by measurement of coefficient of restitution

- IS 13630 (Part‑14) – Indian Standard equivalent for tile impact resistance.

- Chrome-plated steel ball Ø 19 mm

- Electromagnetic drop device with guide tube

- Rigid concrete block support with tile holding system

- Digital indicator with COR calculator

- Tile mold cube – 75 mm x 75 mm

Optional Accessories (Available at Extra Cost):

- Environmental Conditioning Chamber: Temperature/humidity stabilization

- Drying Oven: For pre-test drying of tiles

- Magnifying Glass / Microscope: Post-impact inspection

- Compressed Air Blower / Brush: Cleaning tile surface prior to testing

You may also like…

Advanced Triaxial Test System (UU–CU–CD Capable) (AZA 1296)

- UU–CU–CD test modes for complete soil strength profiling

- Automated control of pressure, load, and drainage

- Compatible with clay, silt, sand, and mixed soils

- Integrated data acquisition and real-time graphing

- Meets ASTM D2850, D4767, BS1377, AASHTO standards

- Ideal for geotechnical, research, and academic use

Air Bag Trainer (Model AZA1246)

Alternator Trainer (Model AZA1247)

Arc Welding Machine (AZA 1234)

AutoDist‑86 Glass Distillation (AZA 1282)

AutoFlash – Automated Abel Flash Point Analyzer( AZA 1277)

AZA Lab's AutoFlash-1277 is a fully automated, microcontroller-based Abel Flash Point Analyzer designed to accurately determine the flash points of combustible liquids. Conforming to IP 170, ISO 13736, and IS 1448 (P:20) standards, it ensures precise and safe analysis of samples in the temperature range of -30°C to 70°C, extendable up to 110°C.

Equipped with a built-in PC and touchscreen display, the AutoFlash-170 delivers intuitive operation, automated calibration, advanced ignition options, and rapid heating procedures for high-efficiency testing. Ideal for laboratories, petrochemical industries, and quality control applications, this standalone unit streamlines the testing process with enhanced accuracy, safety interlocks, and programmable procedures.

Related products

FLUX OVEN – 50 KG – STAINLESS STEEL (AZA -1273)

The AZA LAB Flux Oven (50 kg capacity) is a high-performance drying oven designed for precise and uniform heating of flux materials in laboratory and industrial environments. Built with a durable double-walled structure, the oven ensures energy efficiency and thermal stability, making it ideal for demanding applications in ceramics, metallurgy, and materials processing.

With a temperature range of 50°C to 400°C, this oven is equipped with forced air circulation, PID temperature control, and even heat distribution, guaranteeing consistent performance. Safety features include over-temperature protection with an audio alarm, and compatibility with optional data logging systems.

Gloss Meter – Triple Angle Models ( AZA 1298 A)

- Measures gloss at 20°, 60°, and 85° angles

- High-precision surface finish inspection

- Widely used in paint, plastic, and coating industries

- Calibration certificate included

- Large backlit LCD for real-time readings

- Conforms to ASTM D523, ISO 2813, and GB/T 9754

- USB interface for data transfer

- Compact, portable, and easy to operate

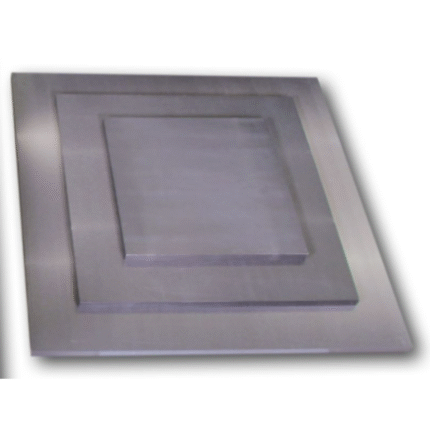

MASTER CALIBRATING PLATE / ZEROING PLATE (AZA – 1270)

AZA LAB's Master Calibrating Plate—also known as a Zeroing Plate—is a precision-engineered aluminum reference plate designed for accurate calibration of Universal Gauges and Plucometers. Manufactured in compliance with IS 13630 (Part-1) and EN ISO 10545 (Part-2) standards, it ensures reliable and repeatable zero-point reference during dimensional testing of ceramic tiles and similar materials.

The plate is available in a wide range of sizes to suit various laboratory and industrial applications. With a flatness accuracy of ±0.1 mm and a sturdy 12 mm thickness, it provides a stable and durable base for equipment calibration.

Whether in QC labs or production floors, the AZA LAB Zeroing Plate is an essential tool for maintaining measurement consistency and ensuring compliance with international tile testing standards.

PORTABLE DIGITAL GAUGE – DIAGONAL LINEARITY PLUCOMETER (AZA – 1272)

The AZA LAB Portable Digital Gauge – AZA 1272 is a compact and highly accurate plucometer designed for evaluating diagonal linearity and flatness of ceramic tiles. It complies fully with IS 13630 (Part-1) and EN ISO 10545 (Part-2), making it an essential tool in laboratories and tile manufacturing quality control.

Engineered for portability and precision, the device allows fast and direct measurement of dimensional deviations across the diagonal of the tile.

AVAILABLE PLUCOMETER SIZES

-

450 × 450 mm

-

600 × 600 mm

APPLICATIONS

-

Measurement of diagonal linearity

-

Evaluation of tile flatness

-

In-process and final quality control in ceramic tile production

-

Conformance testing as per national and international standards

ROTAP SIEVE SHAKER (AZA 1302)

- Rotap Sieve Shaker for particle size analysis

- Compatible with standard 8” or 12” test sieves

- Built-in digital timer with precise control

- Uniform tapping & vibration for reproducible results

- Ideal for aggregates, powders, and soil testing

- Rugged construction for long-term lab use

- Reduces manual sieving time and improves accuracy

Test Specimen Holder for Surface Abrasion Machine – For Glazed Tiles (AZA 1264)

Test Specimen Holder for Surface Abrasion Machine – For Glazed Tiles (AZA 1264A)

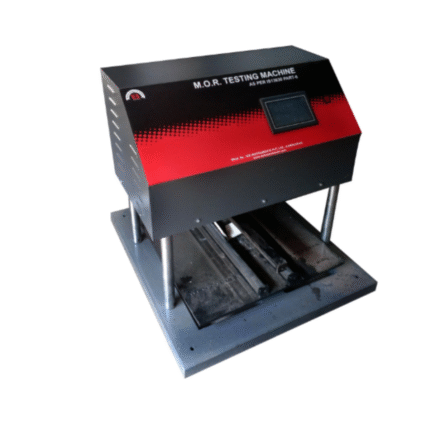

WET TRANSVERSE STRENGTH TESTING MACHINE (AZA -1268)

The Wet Transverse Strength Testing Machine is a rugged electro-mechanical system designed for quiet, vibration-free operation. It features a precision load control system driven by an integrated induction motor and drive, ensuring consistent and repeatable test results.

Suited for laboratories, R&D departments, and quality control units in cement tile manufacturing.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items

Reviews

There are no reviews yet.