SEMI AUTOMATED CLEVELAND OPEN CUPFLASH POINT ANALYZER(AZA‑1289)

- Semi-automated Cleveland Open Cup flash point tester

- Conforms to ASTM D92 and ISO 2592

- Suitable for petroleum, lubricants, and chemical testing

- Manual sample cup handling with automated ignition

- Built-in digital temperature display

- Compact benchtop design with safety features

- High accuracy thermocouple monitoring

- Cost-effective alternative to full automation

Description

Flash Point Analyzer Semi Automated Cleveland Open Cup is engineered for high-precision flash point testing, adhering strictly to ASTM D92 standards. This semi-automated unit is ideal for laboratories requiring robust, cost-effective flash point determination for oils, fuels, and other volatile liquids. With a perfect balance between automation and manual control, it suits medium- to high-throughput testing environments in both industrial and academic settings.

The flash point of a substance indicates the lowest temperature at which its vapors ignite when exposed to an open flame. This is critical for determining the fire hazard associated with flammable liquids. The Cleveland Open Cup (COC) method, particularly for substances with flash points above 79°C, is globally recognized and mandated in quality control and regulatory settings. According to [astm.org/Standards/D92.htm] (non-clickable), ASTM D92 ensures consistency and accuracy in measuring flash and fire points.

The analyzer features a semi-automated gas ignition system with a pilot flame that automatically traverses the cup at preset temperature intervals. A sensitive flame detection sensor identifies the flash point with minimal operator input. The test ends automatically once ignition is detected, and results are displayed on a digital screen for immediate reading and data recording.

The heating mechanism uses a thermostatically controlled aluminum block to ensure uniform heat distribution across the test cup. This guarantees a stable temperature rise rate as per ASTM protocol. The stainless steel cup is corrosion-resistant and easily removable for cleaning and replacement.

Operators can easily adjust the temperature ramp rate, ignition timing, and test duration via a digital control panel. An inbuilt timer alerts the user to critical stages, while the safety system includes a gas cut-off and temperature limiter to prevent overheating. These features ensure compliance with both laboratory safety guidelines and industry regulations.

The semi-automated configuration is ideal for labs needing flexibility—automated ignition and detection reduce human error, while manual sample handling provides control over test setup. This makes it suitable for use in refineries, lubricant manufacturers, transport safety departments, and fire testing labs.

In terms of connectivity, the system includes USB ports for data transfer and compatibility with most LIMS platforms. Test results can be printed or archived for traceability. The unit is bench-top friendly, with a compact design that fits into any lab workflow.

Technicians and quality managers appreciate its low maintenance needs, straightforward operation, and long service life. The included calibration tool ensures ongoing accuracy, making it an excellent return on investment.

To learn more about the ASTM D92 test method and its importance, visit [astm.org/Standards/D92.htm] (non-clickable).

For more details on ASTM D92 methodology, refer to standard documentation via [www.astm.org/Standards/D92.htm] (non-clickable as requested).

Specifications:

| Feature | Details |

|---|---|

| Test Method | Cleveland Open-Cup (ASTM D92) |

| Flash Point Range | Ambient to 400°C |

| Fire Point Detection | Yes |

| Sample Cup Capacity | 75 ml |

| Heating Rate | Programmable, as per ASTM D92 |

| Ignition Source | Electric or gas, automatic |

| Temperature Measurement | Digital display with thermocouple |

| Safety Systems | Over-temp shutoff, ignition shield |

| Power Supply | 230V AC, 50/60 Hz |

| Dimensions (W x D x H) | 32 x 38 x 40 cm |

| Weight | 13 kg |

Frequently Asked Questions (FAQ):

Q1: What makes this model semi-automated?

A: The heating and ignition process are automated, but cup placement and lid operation are manual, offering operator control with some automation benefits.

Q2: Is this analyzer compliant with international testing standards?

A: Yes, it fully complies with ASTM D92 and ISO 2592 for open-cup flash and fire point determination.

Q3: Can it be upgraded to a fully automated version later?

A: No direct upgrade path is offered, but a fully automated version is available separately for labs needing advanced features.

Q4: What materials can be tested with this analyzer?

A: It is suitable for petroleum products, lubricants, and chemical solutions with flash points above 79°C.

Q5: How is this different from a manual Cleveland Open Cup tester?

A: Unlike manual testers, it includes an automatic ignition system and programmable heating, improving accuracy and safety.

Additional information

| Test Method |

Cleveland Open-Cup (ASTM D92) |

|---|---|

| Flash Point Range |

Ambient to 400°C |

| Fire Point Detection |

Yes |

| Sample Cup Capacity |

75 ml |

-

Automated operation with an 8.4″ touchscreen, easy one-click start, and audible alerts on completion

-

Rapid heating modes: Standard, rapid, or user-defined rates (1–20 °C/min)

-

Versatile ignition: Switch easily between gas or electric igniter sources

-

Unknown sample detection: Built-in “search” mode to automatically locate flash point in unmarked samples

-

Safety & precision: Automatic barometric pressure correction and comprehensive interlocks ensure reliable operation

-

Power: 230 VAC, 50 Hz, 1.5 kW

-

Heating: 1000 W coil heater (230 V) with precise thermal profiling

-

Cooling: Integrated centrifugal blower (56.5 CFM) for rapid cooldown

-

Measurement: PT100 Class A sensors on sample (0–400 °C) and bath (0–500 °C); ionization ring flash detection; ambient pressure range: 700–1100 hPa

-

Dimensions & Weight: W 410 × D 420 × H 330 mm; approx. 16 kg

-

Environmental: Operational in 10–35 °C at ≤80% RH

You may also like…

Advanced Triaxial Test System (UU–CU–CD Capable) (AZA 1296)

- UU–CU–CD test modes for complete soil strength profiling

- Automated control of pressure, load, and drainage

- Compatible with clay, silt, sand, and mixed soils

- Integrated data acquisition and real-time graphing

- Meets ASTM D2850, D4767, BS1377, AASHTO standards

- Ideal for geotechnical, research, and academic use

Air Bag Trainer (Model AZA1246)

Alternator Trainer (Model AZA1247)

Arc Welding Machine (AZA 1234)

AutoDist‑86 Glass Distillation (AZA 1282)

AutoFlash – Automated Abel Flash Point Analyzer( AZA 1277)

AZA Lab's AutoFlash-1277 is a fully automated, microcontroller-based Abel Flash Point Analyzer designed to accurately determine the flash points of combustible liquids. Conforming to IP 170, ISO 13736, and IS 1448 (P:20) standards, it ensures precise and safe analysis of samples in the temperature range of -30°C to 70°C, extendable up to 110°C.

Equipped with a built-in PC and touchscreen display, the AutoFlash-170 delivers intuitive operation, automated calibration, advanced ignition options, and rapid heating procedures for high-efficiency testing. Ideal for laboratories, petrochemical industries, and quality control applications, this standalone unit streamlines the testing process with enhanced accuracy, safety interlocks, and programmable procedures.

Related products

AUTOMATED CLEVELAND OPEN CUP FLASH POINT ANALYZER(AZA 1279)

Flash-92s – Cleveland Open Cup Flash Point Analyzer(AZA 1291)

- Flash Point Analyzer with Cleveland Open Cup method

- Fully compliant with ASTM D92 standards

- Ideal for petroleum, lubricant, and chemical testing

- Precise ignition detection with automatic control

- Safety-enhanced with flame protection and exhaust

- User-friendly touchscreen with real-time data logging

- USB and Ethernet connectivity for LIMS integration

- Compact, durable stainless steel test chamber

Fully Automated Atmospheric Distillation Analyzer (AZA 1287)

- Complies with ASTM D86 for atmospheric distillation

- Fully automated operation from start to residue

- Real-time display of temperature and volume curves

- Built-in safety, cooling, and error detection systems

- Touchscreen user interface with method presets

- USB, LAN, and LIMS data connectivity

- Suitable for diesel, gasoline, and jet fuel analysis

- Fast, repeatable, and compliant distillation results

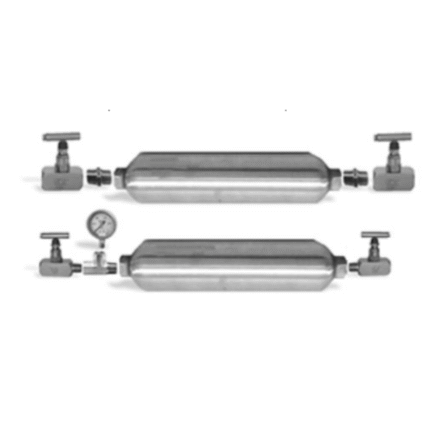

Oil & Gas Sampling Cylinders Single End with Dip Line (AZA- 1274)

AZA LAB Sampling Cylinders & Gas Sampling Bombs are robust, high‑pressure vessels engineered for safe, reliable collection, storage, and transport of liquids and gases in demanding industrial environments. Available in single‑ended, double‑ended, and flat‑ended variants, they are constructed from premium materials like stainless steel (304/316 L) and Monel, offering corrosion resistance and durable performance . TPED, CE, and ISO certifications ensure compliance with international safety and transport regulations. Each cylinder features precision-engineered NPT connections (¼″ or ½″), customizable volumes from 150 cc to 10 L, and pressure ratings up to 5000 psig, making them ideal for applications in refineries, petrochemical labs, chromatographic analysis, and gas sampling in high‑pressure systems . Hydrostatic testing guarantees reliable integrity under rigorous conditions, while additional options—such as specialized valves, burst discs, dip tubes, and protective carrying cases—allow for tailored configurations to meet specific sampling needs.

Oil & Gas Sampling Cylinders with Double & Triple Ended (AZA -1274 A)

- Model: AZA-1274 A

- Available in single, double, and triple-ended designs

- Manufactured from SS 304 / SS 316 / Monel for corrosion resistance

- Pressure tested and certified (CE, TPED, ISO, DOT)

- Capacity range: 100 cc to 5000 cc

- Max pressure: Up to 3000 psi (206 bar)

- Standard ¼″ or ½″ NPT connections

- Optional dip tubes and custom thread fittings

Precision Automated Distillation Analyzer (AZA 1281)

Semi‑Manual Distillation Analyzer(AZA 1286)

- Semi-manual control with digital precision

- Follows ASTM D86 for petroleum distillation

- Ideal for gasoline, diesel, kerosene & jet fuel

- Real-time temperature and volume tracking

- Integrated safety features and alarms

- Suitable for educational, QA/QC, and R&D labs

- Digital thermoregulation with high accuracy

- Cost-effective solution for mid-volume testing

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items

Reviews

There are no reviews yet.