High-precision Thermal Expansion Measurement for Ceramics & Solids (AZA -1269)

This high-precision dilatometer is engineered for measuring the coefficient of linear thermal expansion of ceramic materials and related solid specimens. Designed for accurate thermal characterization, the system integrates a robust furnace, precision-controlled heating, and a sensitive displacement measurement system based on LVDT technology.

| Feature | Specification |

|---|---|

| Heating Element | Special Silicon Carbide (single-end element) |

| Operation Voltage | 5 Amps / 230 V AC |

| Maximum Temperature | 1200 °C |

Description

EXPANSION MEASUREMENT SYSTEM

| Feature | Specification |

|---|---|

| Measurement Technique | LVDT (Linear Variable Differential Transformer) – MASSETRON (German make) |

| Measurement Accuracy | 1 Micron |

| Readout | Digital display + Computerized output |

| Software Interface | Custom-built software with LabVIEW platform |

| Computer System | Latest PC with inkjet printer included |

| Measuring Range | 0 – 2000 Microns |

| Specimen Size | 10 × 10 × 45 mm ±2 mm |

| Probe & Tube Material | High-purity recrystallized alumina |

| Calibration Certificates | a) For LVDT (expansion) |

| Feature | Specification |

|---|---|

| Equipment Dimensions | Approx. 250 × 1000 × 300 mm |

| Shell Construction | Double-wall MS body, powder-coated |

| Insulation | Low thermal mass zirconia blend fiber board |

| Furnace Movement | Linear bearing wheels on stainless steel rails for smooth sliding & accurate positioning |

| Feature | Specification |

|---|---|

| Controller | NIPPON/TAIE PID programmable digital controller (with K-type thermocouple) |

| Temperature Accuracy | ±1 °C |

| Safety Controller | Air-break magnetic contactor to prevent overheat from thyristor failure |

| Thyristor System | Phase-angle control with isolation transformer |

| Indicators | - Digital Ammeter & Voltmeter |

Related products

DEEP ABRASION MACHINE FOR UNGLAZED TILES (AZA 1260)

ELECTRONIC WEIGHING BALANCE (AZA-1267)

FLUX OVEN – 50 KG – STAINLESS STEEL (AZA -1273)

The AZA LAB Flux Oven (50 kg capacity) is a high-performance drying oven designed for precise and uniform heating of flux materials in laboratory and industrial environments. Built with a durable double-walled structure, the oven ensures energy efficiency and thermal stability, making it ideal for demanding applications in ceramics, metallurgy, and materials processing.

With a temperature range of 50°C to 400°C, this oven is equipped with forced air circulation, PID temperature control, and even heat distribution, guaranteeing consistent performance. Safety features include over-temperature protection with an audio alarm, and compatibility with optional data logging systems.

Gloss Meter – Single Angle Models ( AZA 1298)

The Single Angle Gloss Meter from AZA Lab is a compact, lightweight, and fully portable instrument designed for fast and accurate measurement of surface gloss. It is ideal for use across a wide range of materials including ceramics, paper, granite, paint, laminates, plastic, marble, and porcelain.

This microprocessor-based unit offers high reliability and ease of use, making it perfect for both quality control in production environments and on-site testing. It features a clear digital display with a HOLD function, averaging capability for up to 20 readings, and auto power-off for battery conservation.

Supplied complete with a rechargeable battery, charger, and calibrated high/low standards, the AZA-GM-S is a dependable tool for consistent and professional gloss measurement at a fixed geometry (20°, 45°, or 60° as per user selection).

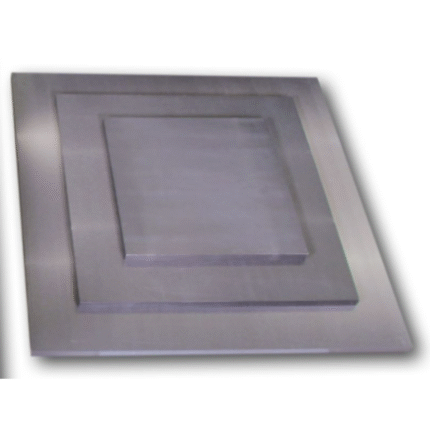

MASTER CALIBRATING PLATE / ZEROING PLATE (AZA – 1270)

AZA LAB's Master Calibrating Plate—also known as a Zeroing Plate—is a precision-engineered aluminum reference plate designed for accurate calibration of Universal Gauges and Plucometers. Manufactured in compliance with IS 13630 (Part-1) and EN ISO 10545 (Part-2) standards, it ensures reliable and repeatable zero-point reference during dimensional testing of ceramic tiles and similar materials.

The plate is available in a wide range of sizes to suit various laboratory and industrial applications. With a flatness accuracy of ±0.1 mm and a sturdy 12 mm thickness, it provides a stable and durable base for equipment calibration.

Whether in QC labs or production floors, the AZA LAB Zeroing Plate is an essential tool for maintaining measurement consistency and ensuring compliance with international tile testing standards.

PORTABLE DIGITAL GAUGE – DIAGONAL LINEARITY PLUCOMETER (AZA – 1272)

The AZA LAB Portable Digital Gauge – AZA 1272 is a compact and highly accurate plucometer designed for evaluating diagonal linearity and flatness of ceramic tiles. It complies fully with IS 13630 (Part-1) and EN ISO 10545 (Part-2), making it an essential tool in laboratories and tile manufacturing quality control.

Engineered for portability and precision, the device allows fast and direct measurement of dimensional deviations across the diagonal of the tile.

AVAILABLE PLUCOMETER SIZES

-

450 × 450 mm

-

600 × 600 mm

APPLICATIONS

-

Measurement of diagonal linearity

-

Evaluation of tile flatness

-

In-process and final quality control in ceramic tile production

-

Conformance testing as per national and international standards

ROTAP SIEVE SHAKER (AZA 1302)

The AZA LAB ROTAP Sieve Shaker is a precision-engineered mechanical device designed for accurate particle size analysis in materials such as soil, sand, cement, aggregates, and powders. Combining rotary and tapping actions, it offers consistent, repeatable performance and complies with most national and international standards for sieve testing.

With rugged construction and intuitive operation, this shaker supports a wide range of test sieves and is suitable for demanding laboratory and industrial environments.

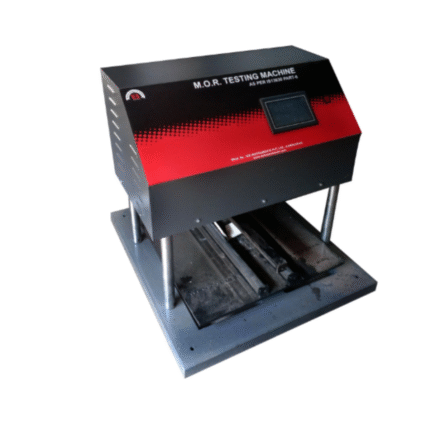

WET TRANSVERSE STRENGTH TESTING MACHINE (AZA -1268)

The Wet Transverse Strength Testing Machine is a rugged electro-mechanical system designed for quiet, vibration-free operation. It features a precision load control system driven by an integrated induction motor and drive, ensuring consistent and repeatable test results.

Suited for laboratories, R&D departments, and quality control units in cement tile manufacturing.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items

Reviews

There are no reviews yet.