AZA 1064 HUMIDITY CHAMBER

- Ideal for stability & environmental testing

- Precise temperature & humidity control

- PID digital controller with display

- Double-walled insulated construction

- Stainless steel inner chamber

- Available in various capacities

Description

A humidity chamber is an essential instrument for laboratories, pharmaceutical firms, food industries, and research institutions where controlled humidity and temperature conditions are required for product stability and environmental testing. At Azalab, we offer high-precision humidity chambers engineered for reliable, long-duration testing under simulated climate conditions.

These chambers are specifically designed to provide a uniform and constant humidity and temperature environment inside the test chamber. They help determine the shelf life, stability, and performance of products under varying environmental conditions. Humidity chambers are vital in drug stability testing, electronics evaluation, packaging analysis, material aging simulation, and more.humidity chamber, stability chamber, lab humidity testing, environmental chamber, pharma stability test.

Key Features:

-

✅ Wide Humidity Range: Typically from 40% to 95% RH

-

✅ Broad Temperature Range: +10°C to +60°C or more

-

✅ PID Microprocessor Control: Ensures precise and stable settings

-

✅ Humidity Generation System: Uses water reservoir and steam injection or ultrasonic system

-

✅ Data Logging: Optional printer or USB interface for long-term monitoring

-

✅ Alarm System: Audible/visual alert for temperature/humidity deviation

-

✅ High-Grade SS Interior: Corrosion-resistant and easy to sanitize

-

✅ Double-Walled Design: Efficient insulation to reduce thermal loss

Applications:

-

💊 Pharmaceutical Stability Testing: Ensures drug efficacy under varying storage conditions

-

🧪 Chemical & Material Testing: For polymers, coatings, plastics, and composite materials

-

📦 Packaging Industry: To analyze the endurance of packaging material against environmental stress

-

🧫 Microbial Culture Studies: Maintains required humidity levels for biological samples

-

🔬 Electronics Testing: Simulates high-moisture environments for PCB and component durability

-

🍫 Food Shelf-Life Analysis: Tests food packaging and product response to environmental changes

Specifications:

| Specification | Details |

|---|---|

| Temperature Range | +10°C to +60°C (extendable if required) |

| Humidity Range | 40% to 95% RH |

| Inner Chamber Material | Stainless Steel (SS 304 grade) |

| Outer Body | Mild Steel with powder coating |

| Control System | PID Microprocessor Controller |

| Display | Digital LED or LCD |

| Alarm | Audio/Visual for deviation detection |

| Capacity | 90L / 180L / 300L / Custom sizes available |

| Power Supply | 220V AC, 50Hz |

| Insulation | Polyurethane foam or glass wool |

| Humidity Source | Steam generator or ultrasonic humidifier |

| Shelves | Adjustable stainless steel shelves |

| Optional Accessories | Data logger, RS-232 interface, printer port |

External Resource:

For global standards and testing protocols, refer to ICH Guidelines Q1A (R2) for pharmaceutical stability testing, available at the International Council for Harmonisation (ich.org).

Frequently Asked Questions (FAQ):

Q1: What is the main purpose of a humidity chamber?

A: It simulates temperature and humidity conditions to test the stability and performance of products, especially in pharmaceuticals and materials research.

Q2: Can I use the humidity chamber for 24/7 testing?

A: Yes. All Azalab humidity chambers are designed for continuous long-duration operation with stable performance.

Q3: How accurate is the humidity and temperature control?

A: The PID controller maintains high precision—usually ±1°C for temperature and ±3% RH for humidity.

Q4: Is distilled water necessary for the humidifier?

A: Yes. To maintain sensor longevity and accurate humidity generation, distilled or demineralized water is recommended.

Q5: Can I connect the chamber to a computer for monitoring?

A: Absolutely. Models come with optional USB, RS-232, or printer port for data recording and audit trails.

Q6: Does the chamber support GMP/GLP compliance?

A: Yes. All units can be validated and calibrated as per GMP/GLP requirements with proper documentation.

Additional information

| Temperature Range |

+10°C to +60°C (extendable if required) |

|---|---|

| Humidity Range |

40% to 95% RH |

| Inner Chamber Material |

Stainless Steel (SS 304 grade) |

| Outer Body |

Mild Steel with powder coating |

You may also like…

AZA 0807 JOLTING APPARATUS

- Standard-compliant jolting apparatus for cement mortar

- Ideal for compacting 40x40x160 mm prism specimens

- Delivers 60 jolts per minute for uniform compaction

- Automatic timer, safety shield & heavy-duty motor

- Used in cement labs, R&D, and educational institutions

- Meets IS 10080, ASTM, and EN testing requirements

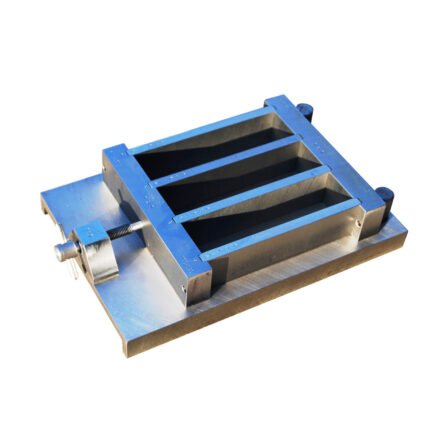

AZA 0808 PRISM MOULD THREE GANG

- Triple-cavity unit for mortar sample casting

- Ideal for compressive/flexural testing

- IS/EN-compliant precision mould

- Lab-grade cast iron build

- Smooth de-moulding and cleaning

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items