AZA 1109 J-RING, NARROW GAP

- AZA 1109 J-Ring for SCC passing ability test

- Narrow gap design for stringent testing conditions

- Simulates rebar obstruction in congested zones

- Measures flow diameter, T50, and blockage

- Compliant with ASTM C1621, EFNARC guidelines

- Works with standard slump flow cone

- Durable steel construction for repeated lab use

Description

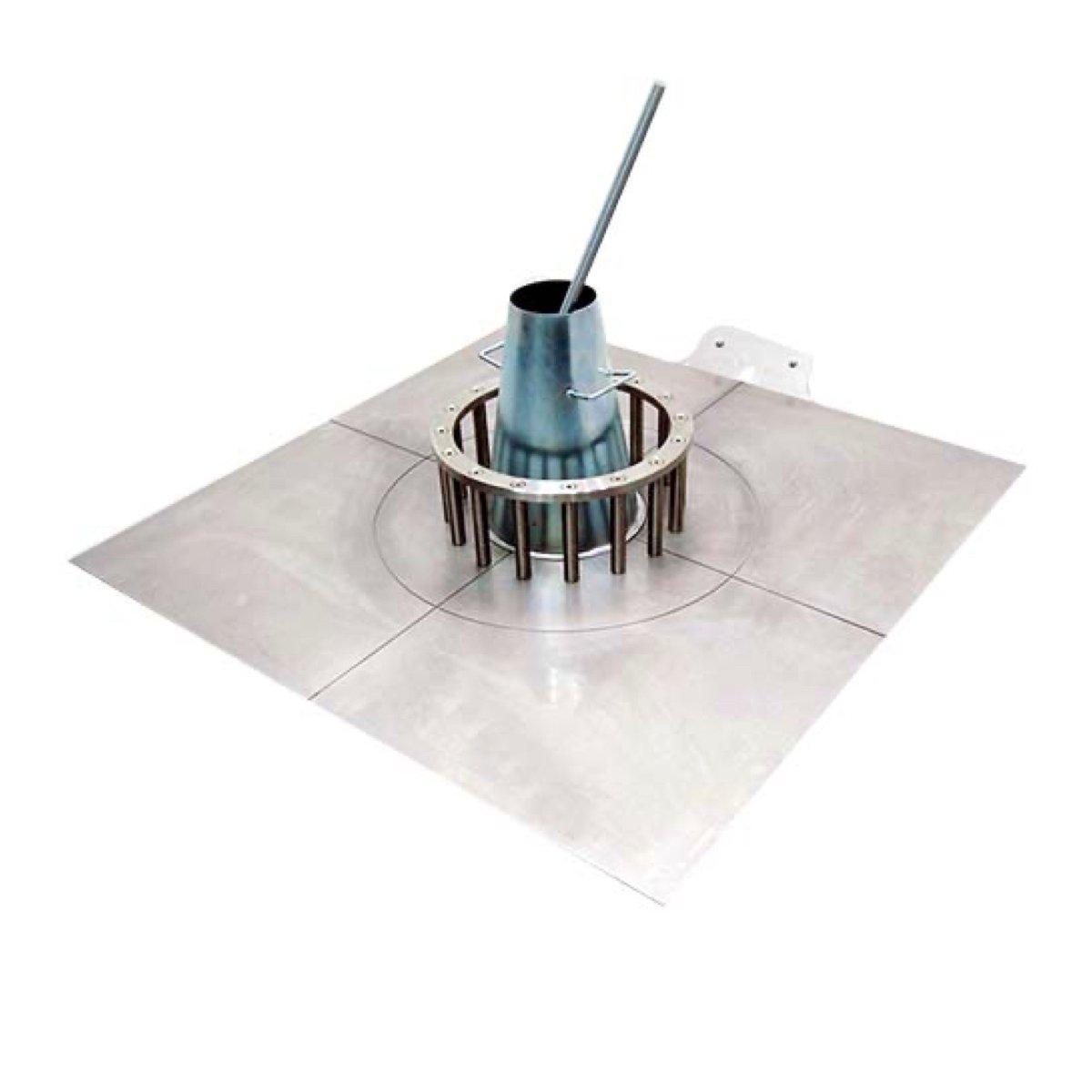

AZA 1109 J-RING, NARROW GAP – Self-Compacting Concrete Testing Apparatus

The AZA 1109 J-Ring, Narrow Gap is a precise laboratory apparatus used to assess the passing ability of Self-Compacting Concrete (SCC) through reinforcement-like obstructions.Used in both research and quality control environments, this narrow-gap variation of the J-Ring test is more stringent, simulating congested reinforcement layouts in real-world construction. Designed in accordance with international SCC testing standards, this equipment helps determine if SCC can flow freely around rebars without segregation or blockage.

Used in both research and quality control environments, this narrow-gap variation of the J-Ring test is more stringent, simulating congested reinforcement layouts in real-world construction. The apparatus works in conjunction with a slump flow cone to measure flow diameter, flow time, and blocking assessment.

🔍 Key Features & Applications

-

Simulates tight reinforcement conditions

-

Accurately assesses SCC’s passing ability

-

Compatible with standard slump flow cone

-

Widely used in construction QC, R&D, and site testing labs

-

Conforms to ASTM C1621, EFNARC Guidelines

🔧 Testing Procedure Overview

-

Place the J-Ring (narrow gap type) on a smooth, non-absorbent surface.

-

Center the slump flow cone inside the ring.

-

Fill the cone with freshly mixed SCC.

-

Raise the cone vertically to allow concrete to flow outward.

-

Measure:

-

Flow diameter

-

Flow time (T50)

-

Difference in flow with and without J-Ring (indicates blocking)

-

-

Analyze results to evaluate the passing ability and viscosity of the mix.

🔗 External Resources (DoFollow Links)

📊 Specifications

| Specification | Details |

|---|---|

| Model | AZA 1109 |

| Type | J-Ring – Narrow Gap |

| Material | Powder-coated steel or stainless steel |

| Number of Rods | 16 uniformly spaced vertical rods |

| Bar Diameter | 18 mm |

| Gap Between Bars | ~41 mm (narrow gap) |

| Complies With | ASTM C1621, EFNARC Guidelines |

| Usage | SCC workability & passing ability testing |

| Setup | Compatible with standard slump cone base |

| Weight | Approx. 5–7 kg |

❓ Frequently Asked Questions (FAQ)

Q1: What is the purpose of the J-Ring Narrow Gap?

A: It tests SCC’s ability to flow through closely spaced rebars without blocking or segregation.

Q2: What does the narrow gap simulate?

A: It simulates highly congested reinforcement areas in concrete structures.

Q3: How does it differ from a standard J-Ring?

A: The narrow gap type has tighter spacing between vertical bars to challenge SCC flow more rigorously.

Q4: What standards apply to this test?

A: ASTM C1621 and EFNARC testing procedures for SCC.

Q5: Can I use this with regular concrete?

A: No, it is designed specifically for self-compacting concrete only.

Q6: What does the narrow gap simulate?

A: It simulates highly congested reinforcement areas in concrete structures.

Additional information

| Model |

AZA 1109 |

|---|---|

| Type |

J-Ring – Narrow Gap |

| Material |

Powder-coated steel or stainless steel |

| Usage |

SCC workability & passing ability testing |

| Setup |

Compatible with standard slump cone base |

| Weight |

Approx. 5–7 kg |

Related products

AZA 1102 SLUMP TEST APPARATUS

- Slump Test Apparatus AZA 1102 for evaluating concrete workability

- Complies with IS 7320 and BS 1881-102 standards

- Durable metal slump cone: 200 mm base, 100 mm top, 300 mm height

- Includes 16 mm diameter tamping rod, 600 mm long, rounded ends

- Suitable for aggregates up to 38 mm size

- Ideal for construction sites, labs, and educational use

- Easy to handle with base plate clamps and lifting handles

AZA 1106 KELLEY BALL PENETRATION APPARATUS

AZA 1107 COMPACTION FACTOR APPARATUS

- Concrete workability tester for dry mixes

- Measures compaction factor with precision

- Double-hopper system with standard trap release

- Conforms to IS 1199 and BS 1881 standards

- Ideal for precast and low-slump concrete testing

- Rugged and portable for field/lab use

- Includes cylindrical container and accessories

AZA 1108 INITIAL SURFACE ABSORPTION TEST (ISAT) APPARATUS

- AZA 1108 ISAT Apparatus for concrete durability testing

- Measures water absorption rate from concrete surfaces

- Follows BS 1881-208 standard procedures

- Useful for bridges, marine structures, water tanks

- High precision setup with capillary tube system

- Records data at 10, 30, and 60-minute intervals

- Sturdy construction ideal for long-term lab use

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items