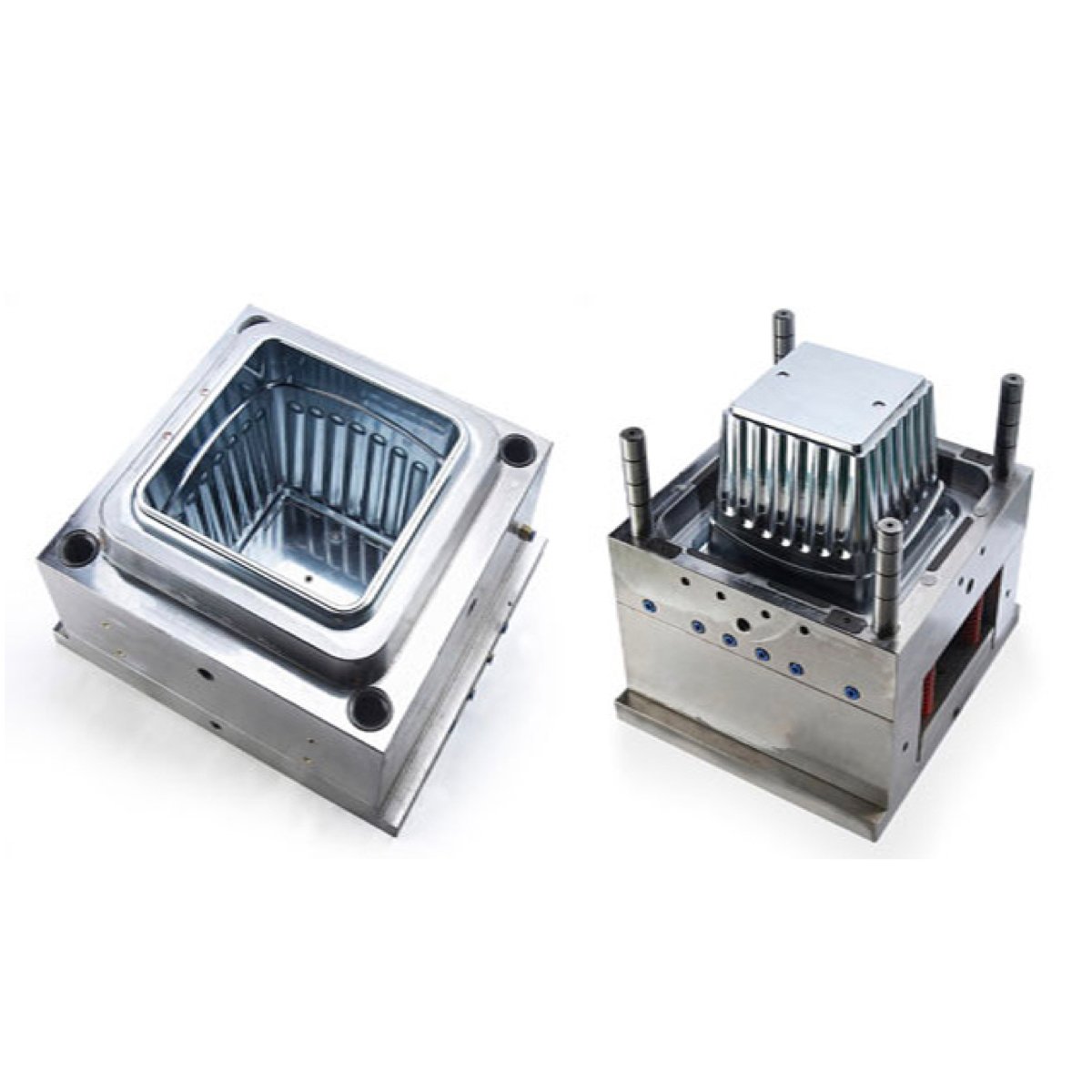

AZA 1125 PLASTIC MOULDS

- One-piece mould – no assembly or screws required

- Made from hard plastic – lightweight, shock-resistant, and non-deformable

- Expel specimens using air or water pressure – fast and clean

- Requires only demould oiling & simple cleaning

- Eco-conscious production – pollution-free and recyclable

- Weighs 1/10th compared to metal moulds – easy to transport and handle

- Conforms to IS 516 / ASTM / BS standards

- Available in 150mm, 100mm, and 50mm sizes

Description

One-Piece Plastic Cube Moulds – 150mm

The Azalab One-Piece Plastic Cube Moulds are the modern alternative to traditional metal moulds, designed to simplify and streamline concrete strength testing. These moulds are made from durable, non-deformable hard plastic, engineered to resist vibration, impact, and wear.

Thanks to their one-piece, seamless construction, there are no bolts, screws, or frames to assemble or maintain. Simply apply demoulding oil before casting and use compressed air or water pressure to release the concrete specimen after curing—no chiseling or damage to the mould or specimen.

These moulds are reusable many times with minimal maintenance, offering excellent dimensional stability and durability even under repetitive lab and site conditions.

As a commitment to sustainability, Azalab manufactures its plastic moulds using a non-polluting, clean process, supporting a greener construction industry. Weighing only a fraction of metal alternatives, they are also easier to transport, store, and handle on-site or in laboratories.aza

Specifications

| Feature | Details |

|---|---|

| Construction | One-piece hard plastic, precision-moulded |

| Sizes Available | 150mm, 100mm, and 50mm cube dimensions |

| Demoulding Method | Compressed air or water pressure |

| Reusability | Yes – for multiple test cycles |

| Cleaning | Simple wash and re-oiling between uses |

| Standards Compliance | IS 516, ASTM C109, BS EN 12390 |

| Weight | ~1/10th of metal cube moulds |

| Finish | Smooth, non-stick internal walls |

| Environmental Impact | Manufactured using eco-friendly, non-toxic process |

Models Available

| Model No. | Cube Size | Description |

|---|---|---|

| AZA-CM-150P-OP | 150 mm | One-piece plastic cube mould |

| AZA-CM-100P-OP | 100 mm | One-piece plastic cube mould |

| AZA-CM-050P-OP | 50 mm | One-piece plastic cube mould (micro testing) |

Applications

-

Concrete compressive strength testing

-

Quality control in cement and construction materials

-

R&D laboratories and academic institutions

-

On-site cube sampling and testing

-

Sustainable construction product testing

Frequently Asked Questions (FAQ)

Q1: How are these different from metal moulds?

They are lighter, easier to demould, and don’t corrode or deform. No mounting is needed.

Q2: How do I release the cube after curing?

Simply use compressed air or water pressure to push the specimen out cleanly.

Q3: Are they reusable?

Yes, with proper cleaning and oiling, they can be reused dozens of times.

Q4: Is this product environmentally friendly?

Yes, it’s manufactured using a non-polluting plastic moulding process and is recyclable.

Q5: Will the plastic withstand concrete vibration?

Yes, the mould is designed to resist vibration, shock, and wear during compaction.

Additional information

| Construction |

One-piece hard plastic, precision-moulded |

|---|---|

| Sizes Available |

150mm, 100mm, and 50mm cube dimensions |

| Standards Compliance |

IS 516, ASTM C109, BS EN 12390 |

Related products

AZA 1101 VEE BEE CONSISTOMETER

- Vee Bee Consistometer for stiff concrete workability testing

- Performs slump test + Vee Bee time for dual accuracy

- Ideal for dry, roller-compacted concrete and pavement mixes

- Vibrating table ensures uniformity in testing

- Includes cone, container, graduated rod & vibration unit

- Built as per IS 1199 and ASTM C1170 standards

- Reliable results in construction material testing labs

AZA 1102 SLUMP TEST APPARATUS

- Slump Test Apparatus AZA 1102 for evaluating concrete workability

- Complies with IS 7320 and BS 1881-102 standards

- Durable metal slump cone: 200 mm base, 100 mm top, 300 mm height

- Includes 16 mm diameter tamping rod, 600 mm long, rounded ends

- Suitable for aggregates up to 38 mm size

- Ideal for construction sites, labs, and educational use

- Easy to handle with base plate clamps and lifting handles

AZA 1107 COMPACTION FACTOR APPARATUS

- Concrete workability tester for dry mixes

- Measures compaction factor with precision

- Double-hopper system with standard trap release

- Conforms to IS 1199 and BS 1881 standards

- Ideal for precast and low-slump concrete testing

- Rugged and portable for field/lab use

- Includes cylindrical container and accessories

AZA 1109 J-RING, NARROW GAP

- AZA 1109 J-Ring for SCC passing ability test

- Narrow gap design for stringent testing conditions

- Simulates rebar obstruction in congested zones

- Measures flow diameter, T50, and blockage

- Compliant with ASTM C1621, EFNARC guidelines

- Works with standard slump flow cone

- Durable steel construction for repeated lab use

AZA 1115 MORTAR PENETROMETER

- Complies with ASTM C403 Standard

- Used to determine rate of hardening of mortar

- Spring-loaded stem graduated from 0 to 70 kg (1 kg divisions)

- Includes six interchangeable penetration needles

- Measures 25 mm penetration resistance

- Marked shanks at every 5 mm for depth tracking

- Supplied in a protective wooden carrying case

AZA 1122 CUBE MOULD (METAL)

- Cube Mould AZA 1122: Precision-engineered for 150mm concrete sample casting.

- Material: Constructed from durable metal for long-term use.

- Standard Compliance: Meets IS and BS specifications for concrete testing.

- Design: Rigid construction ensures dimensional accuracy and repeatability.

- Application: Ideal for laboratories, construction sites, and educational institutions.

AZA 1124: BEAM MOULD

- AZA 1124 Beam Mould for concrete flexural strength testing

- Sturdy, corrosion-resistant steel or cast iron construction

- Produces precise concrete beams – 100x100x500 mm or 150x150x700 mm

- Split-mould design for easy de-moulding

- Reusable and lab-compliant with IS & ASTM standards

- Available at Azalab with warranty and expert support

AZA 1127 PLASTIC CYLINDERICAL MOULD

- Made from durable polyurethane – reusable & vibration-resistant

- Available in 150×300 mm and 100×200 mm sizes

- Ideal for IS 10086 / ASTM C470 concrete cylinder testing

- Leak-proof design ensures accurate test results

- Lightweight for easy handling and transportation

- One-piece moulds – no bolts or assembly required

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items