Description

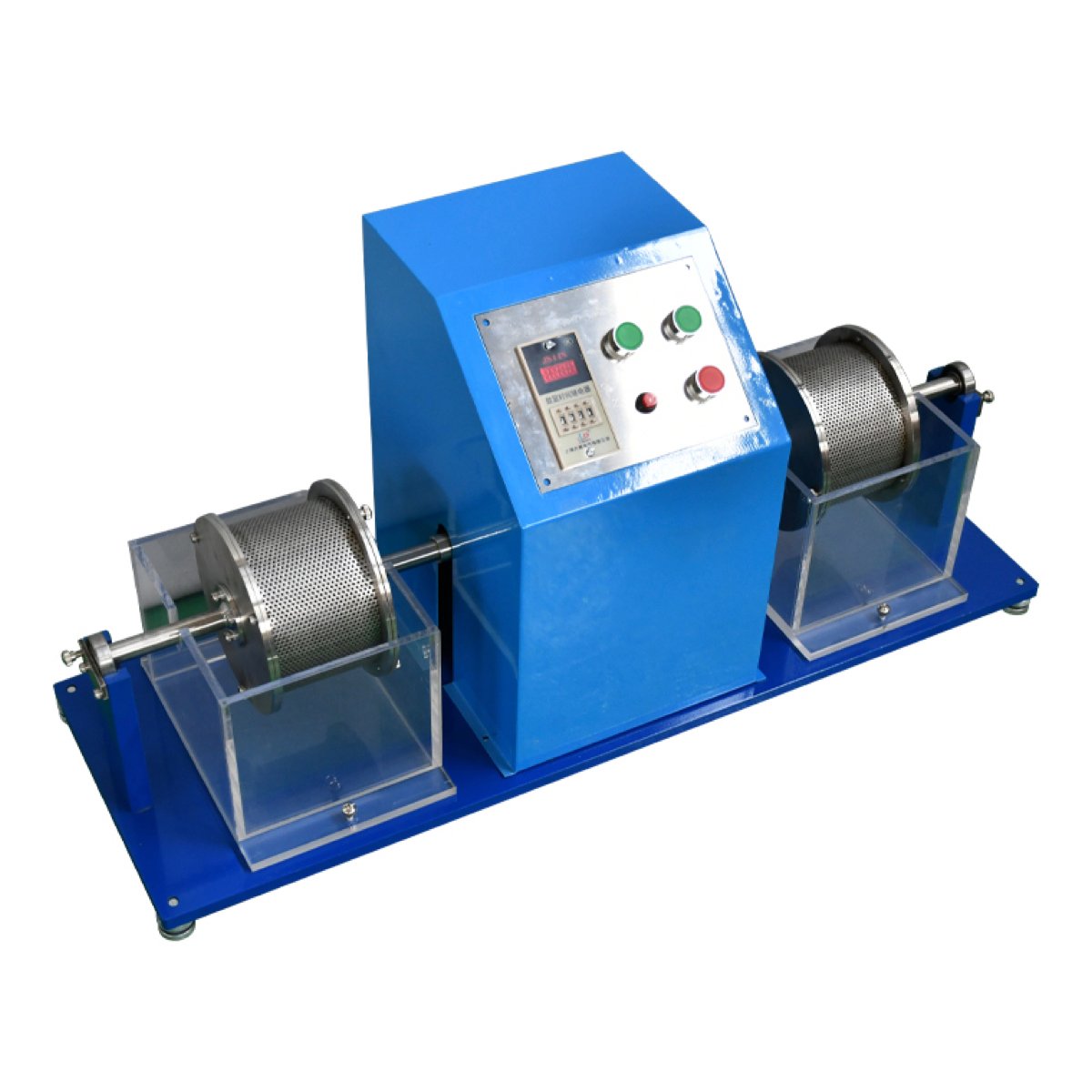

The AZA 1005 Slake Durability Apparatus from Azalab is a precision-engineered testing device used to determine the slake durability index of rocks that are prone to mechanical breakdown or disintegration when subjected to cycles of wetting and drying. This type of test is essential in geotechnical engineering, particularly for assessing weak sedimentary rocks like shales, mudstones, claystones, and marls that can significantly deteriorate under environmental weathering.

Designed for laboratory use but rugged enough for field-based setups, the AZA 1005 provides engineers, researchers, and academic institutions with a reliable method of predicting long-term rock stability, especially for construction projects involving slopes, dams, tunnels, and road cuts.

🌍 Why Slake Durability Testing Matters

Rocks exposed to atmospheric agents like rain, moisture, and temperature variations can degrade rapidly if they are composed of weak minerals or have internal structural flaws. The slake durability test replicates these environmental changes in a controlled lab environment. It helps predict whether a rock will:

-

Retain structural integrity

-

Break into fragments

-

Disintegrate into fine particles over time

The test is particularly useful when evaluating cut slopes, embankments, tunnels, and hydroelectric projects where rock weatherability plays a key role in long-term safety and maintenance.

Evaluates slake durability index of weak rocks

Twin drum configuration for high accuracy

Built per ISRM & ASTM D4644 standards

Ideal for geotechnical labs and universities

Stainless steel drums and drive motor included

⚙️ Key Features of AZA 1005

-

Rotating Drum Assembly: Consists of two stainless steel mesh drums that rotate in a water bath, simulating wet/dry cycles.

-

Variable Speed Motor: Maintains consistent drum rotation speed (typically 20 RPM), ensuring uniform testing.

-

Corrosion-Resistant Frame: All contact parts are made of stainless steel, ensuring long-lasting durability in wet environments.

-

Digital Timer: Allows for precise control over rotation duration (usually 10 minutes per cycle).

-

High Capacity: Suitable for testing two rock samples simultaneously, saving time and enhancing repeatability.

🔬 How It Works

-

Preparation: Rock samples are oven-dried and weighed (W1).

-

Mounting: Placed in mesh drums and immersed partially in distilled water.

-

Rotation: Drums are rotated for 10 minutes in water, then samples are oven-dried again.

-

Repeat Cycle: The process is repeated for a second 10-minute cycle.

-

Final Weighing: Remaining rock fragments are weighed (W2).

-

Slake Durability Index Calculation:

SDI=(W2W1)×100SDI = \left( \frac{W2}{W1} \right) \times 100SDI=(W1W2)×100

A high slake durability index indicates better rock resistance to environmental degradation.

🧾 Specifications

| Feature | Specification |

|---|---|

| Model | AZA 1005 |

| Drums | 2 Stainless Steel Mesh Drums (140mm dia) |

| Drum Speed | 20 ± 2 RPM |

| Motor | 1/4 HP geared motor |

| Timer | Digital, up to 60 minutes |

| Material Compatibility | Shale, Mudstone, Marl, Claystone |

| Bath Tank | Stainless steel |

| Standards Complied | ASTM D4644, ISRM Suggested Methods |

| Power Supply | 220V, 50Hz |

| Weight | ~35 kg |

📚 External Resources & Standards

These references highlight the global acceptance of slake durability tests in geotechnical analysis.

Slake Durability Apparatus, AZA 1005, rock testing equipment, durability test, disintegration test, geotechnical apparatus, Azalab, soil testing

❓ Frequently Asked Questions (FAQ)

Q1: What types of rocks can be tested with this apparatus?

It is best suited for weak rocks like shale, marl, claystone, and mudstone.

Q2: How many samples can I test at once?

The AZA 1005 allows simultaneous testing of two samples using twin drums.

Q3: Does it comply with ASTM standards?

Yes, the apparatus conforms to ASTM D4644 and ISRM recommendations.

Q4: Is the equipment supplied with a water tank?

Yes, a corrosion-resistant stainless steel tank is included for water immersion.

Q5: Is the test fully automatic?

While rotation and timing are automatic, weighing must be done manually.

Related products

AZA 0994 CORE CUTTING/CORE DRILLING MACHINE (PETROL)

AZA 0996 CORE CUTTING/CORE DRILLING MACHINE (MOTORISED)

AZA 0997 ROCK/CONCRETE CUTTING MACHINE

- Exceptional Power: Designed for cutting through tough rock and reinforced concrete.

- Precision Control: Achieves accurate and clean cuts in challenging materials.

- Built to Last: Heavy-duty construction ensures durability in extreme conditions.

- Versatile Applications: Ideal for mining, quarrying, demolition, and infrastructure projects.

- Operator Comfort: Ergonomic design for reduced fatigue during demanding tasks.

AZA 0998 ASPHALT & CONCRETE FLOOR SAW

- Heavy-Duty Performance: Designed for demanding asphalt and concrete cutting tasks.

- Precision Cutting: Achieve clean, straight cuts with advanced blade control.

- Enhanced Durability: Robust construction for long-term reliability on job sites.

- User-Friendly Design: Ergonomic features for comfortable operation and reduced fatigue.

- Versatile Applications: Ideal for road repairs, demolition, trenching, and utility work.

AZA 1001 AUTOMATIC GRINDING MACHINE

AZA 1003 DIGITAL POINT LOAD TEST APPARATUS

- 60 kN capacity hydraulic load frame for rock specimen testing

- Digital display with 2×16 characters for precise load readings

- ±1% accuracy with 32,000 divisions resolution

- Adjustable frame accommodates specimens up to 102 mm diameter

- Load measurement in both kN and MPa units

- Serial port for PC connectivity and data logging

- Complies with ASTM D5731 standards for point load testing

AZA 1004 BRAZILIAN TEST APPARATUS

- Determines indirect tensile strength of cylindrical rock samples

- Complies with ASTM D3967 and ISRM standards

- Strong steel frame with plated loading jaws

- Precision loading and measurement system

- Suitable for laboratory and on-site testing

AZA 1007 LOAD FRAME FOR UNIVERSAL COMPRESSION TEST OF ROCKS12 SPEED 200 KN

- Universal compression test machine for rock specimens

- 200 kN load capacity with 12-speed gear control

- Designed per ISRM and ASTM standards

- Heavy-duty steel frame for maximum stability

- Ideal for geotechnical and civil engineering labs

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items