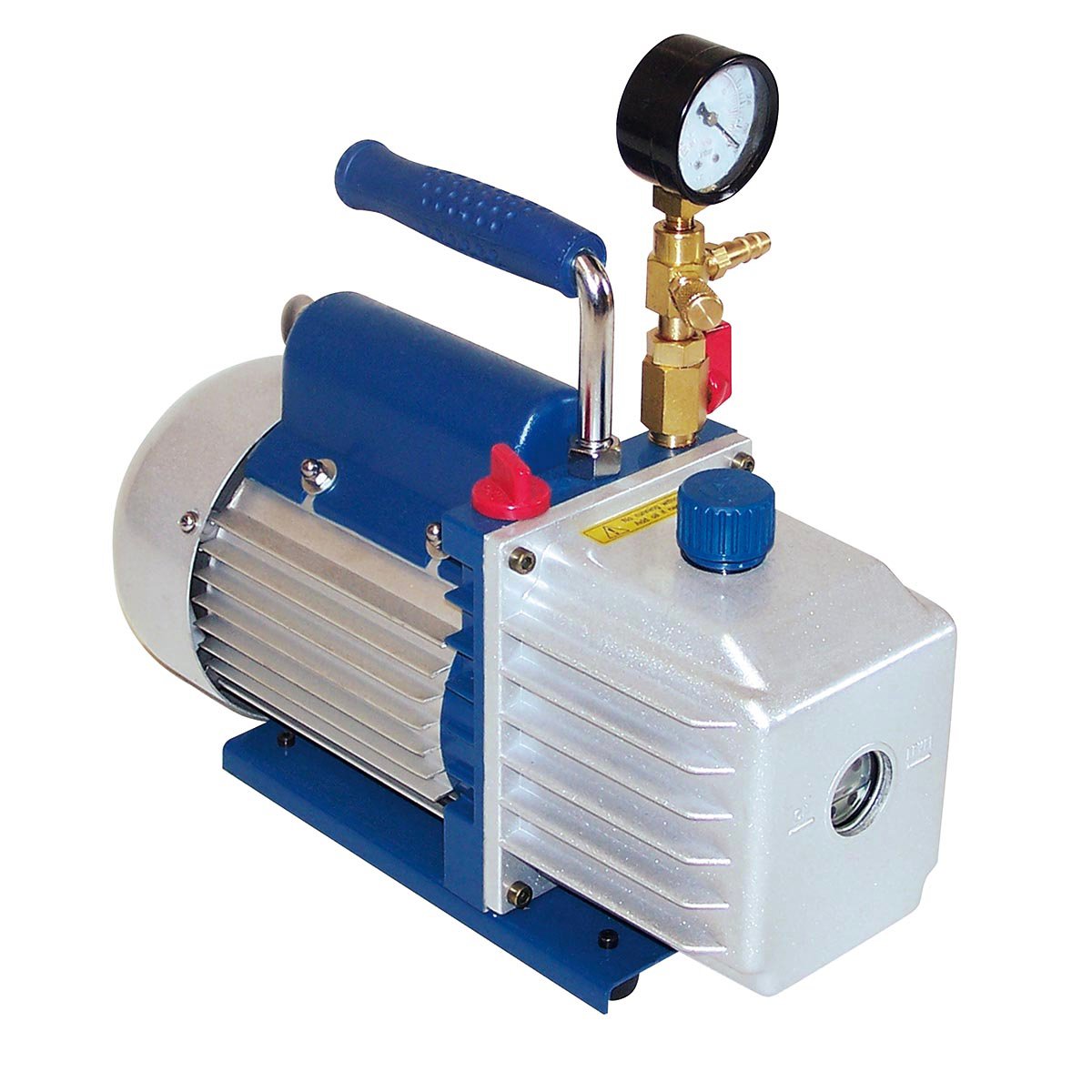

AZA 1062 VACUUM PUMP

- High-performance vacuum pump for lab & industrial use

- Suitable for filtration, distillation, drying & HVAC systems

- Available in oil-free, rotary vane & diaphragm models

- Corrosion-resistant design for chemical handling

- Stable suction, low noise, and long operation life

- Compact and portable for easy integration

Description

A vacuum pump is a fundamental tool across numerous scientific, industrial, and commercial applications. At Azalab, we offer robust and efficient vacuum pumps designed for laboratories, HVAC systems, distillation units, filtration setups, and medical or pharmaceutical operations.

Vacuum pumps work by removing gas molecules from a sealed chamber, thereby creating a vacuum or low-pressure environment necessary for various procedures. From suction filtration and freeze-drying (lyophilization) to degassing solvents or operating vacuum ovens, a dependable pump ensures optimal performance and process accuracy.

Types of Vacuum Pumps Available:

-

Oil-Free Diaphragm Pump

-

Ideal for clean applications such as aqueous filtration or evaporation.

-

Maintenance-free and safe for environments where oil contamination is a concern.

-

-

Rotary Vane Vacuum Pump

-

Suitable for distillation, drying, and degassing.

-

Offers deeper vacuum levels and continuous operation capability.

-

-

Water Aspirator Vacuum Pump

-

Economical choice for basic vacuum requirements in chemical labs.

-

Key Features:

-

✔️ Stable Vacuum Generation: Maintains consistent pressure over prolonged operations.

-

✔️ Chemical-Resistant Build: Models with PTFE components handle corrosive vapors.

-

✔️ Low Noise Operation: Quiet running design enhances lab or office comfort.

-

✔️ Thermal Protection: Automatically shuts down to prevent overheating.

-

✔️ Portable Design: Lightweight with easy-carry handles for flexible usage.

-

✔️ Oil or Oil-Free Models: Choose based on your application’s cleanliness and maintenance needs.

Applications:

-

🧪 Scientific Laboratories: For filtration, vacuum distillation, vacuum drying, and rotary evaporators.

-

🏭 Industrial Settings: Assists in process engineering tasks and vacuum forming.

-

🩺 Medical & Dental Clinics: Used in suction systems and vacuum sterilization.

-

🧊 HVAC Maintenance: Essential for refrigerant evacuation and leak testing.

-

🚰 Water Treatment Labs: Employed for degassing and membrane filtration processes.

-

📦 Packaging & Sealing: Ensures airtight sealing in vacuum packaging units.

Specifications:

| Specification | Details |

|---|---|

| Type | Diaphragm / Rotary Vane / Water Jet |

| Flow Rate | 10 – 100 L/min (model-dependent) |

| Ultimate Vacuum | Up to 0.01 mbar (rotary vane), ~100 mbar (diaphragm) |

| Motor Power | 1/10 HP to 1 HP |

| Material | Aluminium, SS, PTFE (depending on model) |

| Oil Requirement | Optional – Oil-free or oil-lubricated |

| Noise Level | ≤ 60 dB |

| Voltage | 220V / 50 Hz (standard models) |

| Safety Features | Overload protection, thermal shut-off |

| Port Size | 6 mm to 10 mm hose barb |

| Accessories | Vacuum hose, oil (if applicable), instruction manual |

External Resource:

Refer to American Vacuum Society (avs.org) and EPA HVAC Guidelines for more insights on how vacuum pumps are applied in industrial and environmental engineering contexts.

Frequently Asked Questions (FAQ):

Q1: What is the difference between oil-free and rotary vane pumps?

A: Oil-free pumps are low maintenance and ideal for clean operations. Rotary vane pumps provide deeper vacuum levels but require oil changes.

Q2: Can this pump be used with corrosive chemicals?

A: Yes, certain models come with PTFE-coated internals for handling corrosive vapors. Please check the chemical compatibility.

Q3: Is this pump suitable for continuous operation?

A: Yes. Rotary vane pumps are ideal for long-duration tasks, while diaphragm pumps handle intermittent use well.

Q4: Can I use this for HVAC refrigerant evacuation?

A: Absolutely. Select a model designed for HVAC applications with the correct vacuum level and CFM rating.

Q5: How do I maintain the pump?

A: Oil models require periodic oil replacement. Oil-free variants need filter checks and occasional cleaning only.

Q6: What safety features are included?

A: Pumps typically include thermal protection, overload cut-off, and sealed motor housing for safe operation.

Additional information

| Type |

Diaphragm / Rotary Vane / Water Jet |

|---|---|

| Flow Rate |

10 – 100 L/min (model-dependent) |

| Ultimate Vacuum |

Up to 0.01 mbar (rotary vane), ~100 mbar (diaphragm) |

| Motor Power |

1/10 HP to 1 HP |

You may also like…

Advanced Triaxial Test System (UU–CU–CD Capable) (AZA 1296)

The Advance Triaxial UU-CU-CD Test System is a high-precision, fully automated solution designed for conducting a wide range of geotechnical triaxial tests on both undisturbed and remolded soil samples. This advanced system enables accurate execution of Unconsolidated Undrained (UU), Consolidated Drained (CD), and Consolidated Undrained (CU) tests in full compliance with international testing standards such as ASTM D2850, ASTM D4767, and BS 1377.

Built for reliability, repeatability, and lab productivity, the system seamlessly integrates automatic pressure control, load application, data acquisition, and result reporting into a single cohesive unit—eliminating manual errors and saving time during extended testing cycles.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items