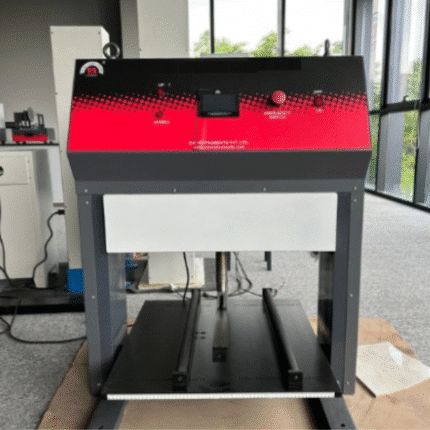

WET TRANSVERSE STRENGTH TESTING MACHINE (AZA -1268)

The Wet Transverse Strength Testing Machine is a rugged electro-mechanical system designed for quiet, vibration-free operation. It features a precision load control system driven by an integrated induction motor and drive, ensuring consistent and repeatable test results.

Suited for laboratories, R&D departments, and quality control units in cement tile manufacturing.

Description

SALIENT FEATURES

-

Standard Digital Model with precision load cell

-

Suitable for fired sample testing on the same unit

-

Tile Size Compatibility: 200 mm, 250 mm, 300 mm, 400 mm

-

Direct digital reading of Load / Collapsing Force

-

Selectable Test Units: Kgf, kN, N/mm² (no manual calculation required)

-

Auto-stop function upon test completion

-

Emergency stop switch for safety

-

7” embedded Touch Screen HMI Controller with intuitive interface

-

Integrated induction motor with drive for smooth and controlled loading

-

Pace rate control accuracy: ±1% at 2000 N/min (2 kN/min)

-

Auto-calibration with cast iron standard weights (weights not included)

-

Adjustable test span with 3 mild steel rollers (12 mm Ø)

-

Safety Guard to protect user from ceramic splinters

-

Powder-coated finish in attractive, corrosion-resistant shades

| Parameter | Specification |

|---|---|

| Capacity | 1000 kgf |

| Least Count | 0.1 kgf |

| Accuracy | ±0.2% of Full Scale |

| Control | Electro-mechanical with drive motor |

| Power Supply | 230 V AC, 50 Hz, Single Phase |

| Overall Dimensions | 914 × 914 × 1143 mm (L × W × D) |

- Cement Tile Manufacturing

-

Construction Materials Testing Labs

-

Civil Engineering Quality Control

-

R&D and Educational Institutions

Related products

Abrasion Testing Machine for Glazed Tiles (AZA 1261)

DEEP ABRASION MACHINE FOR UNGLAZED TILES (AZA 1260)

FLUX OVEN – 50 KG – STAINLESS STEEL (AZA -1273)

The AZA LAB Flux Oven (50 kg capacity) is a high-performance drying oven designed for precise and uniform heating of flux materials in laboratory and industrial environments. Built with a durable double-walled structure, the oven ensures energy efficiency and thermal stability, making it ideal for demanding applications in ceramics, metallurgy, and materials processing.

With a temperature range of 50°C to 400°C, this oven is equipped with forced air circulation, PID temperature control, and even heat distribution, guaranteeing consistent performance. Safety features include over-temperature protection with an audio alarm, and compatibility with optional data logging systems.

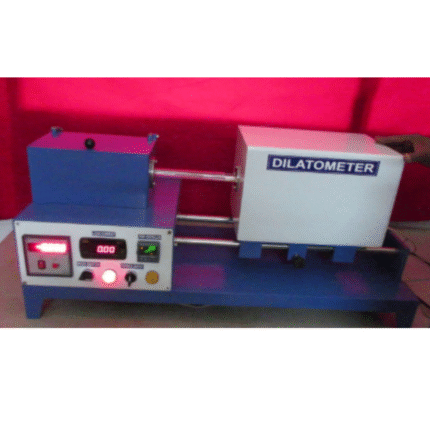

High-precision Thermal Expansion Measurement for Ceramics & Solids (AZA -1269)

| Feature | Specification |

|---|---|

| Heating Element | Special Silicon Carbide (single-end element) |

| Operation Voltage | 5 Amps / 230 V AC |

| Maximum Temperature | 1200 °C |

High-precision Thermal Expansion Measurement for Ceramics & Solids(AZA – 1269 A)

| Feature | Specification |

|---|---|

| Heating Element | High-quality Silicon Carbide element (I Squared R, USA) |

| Operation Power | 15 Amps / 230 V / AC |

| Maximum Temperature | 1400 °C |

| Continuous Operating Temp. | 1400 °C |

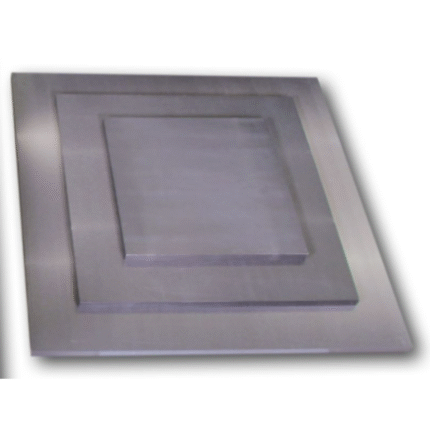

MASTER CALIBRATING PLATE / ZEROING PLATE (AZA – 1270)

AZA LAB's Master Calibrating Plate—also known as a Zeroing Plate—is a precision-engineered aluminum reference plate designed for accurate calibration of Universal Gauges and Plucometers. Manufactured in compliance with IS 13630 (Part-1) and EN ISO 10545 (Part-2) standards, it ensures reliable and repeatable zero-point reference during dimensional testing of ceramic tiles and similar materials.

The plate is available in a wide range of sizes to suit various laboratory and industrial applications. With a flatness accuracy of ±0.1 mm and a sturdy 12 mm thickness, it provides a stable and durable base for equipment calibration.

Whether in QC labs or production floors, the AZA LAB Zeroing Plate is an essential tool for maintaining measurement consistency and ensuring compliance with international tile testing standards.

MOR TESTING MACHINE(AZA-1265)

MOR Testing Machine

High-Performance Flexural Strength Testing for Ceramic Tiles

MOR Testing Machine is a high-precision device designed for determining the Modulus of Rupture (MOR) of ceramic tiles. This test is essential for assessing the bending strength and structural integrity of flooring and wall tiles under stress.

The system features a rugged frame, adjustable supports, and a digital control interface for precise application of force. Whether used in a quality assurance lab or a tile manufacturing facility, this machine ensures compliance with international testing standards

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items

Reviews

There are no reviews yet.