AZA 0803 TENSILE STRENGTH TESTER (ELECTRICALLY OPERATED)

Bs12

The instrument employs a friction free, accurate, double lever system, the load being applied by means of sliding weight on the top lever. The capacity of the units is 900 kgs. After fixing

the briquette in the jaws, the machine is switched on. The sliding weight slides over the calibrated lever thus applying tension to the specimen. A micro switch fitted instantly stop the machine on failure of the briquette and on failure the tensile load is accurately 0.5kg. By means of a marker provided on the sliding weight to its zero position. Suitable for operation on 230 V, 50 cycles, Single Phase, A.C. supply. Supplied complete with one brass briquette mould and one base plate.

Related products

AZA 0791 FLOW TABLE

AZA 0794 FLOW TABLE (MOTORISED)

AZA 0795 LE CHATELIER MOULD

AZA 0798 LENGTH COMPARATOR

AZA 0802 DIGITAL BLAINE AIR PERMEABILITY APPARATUS

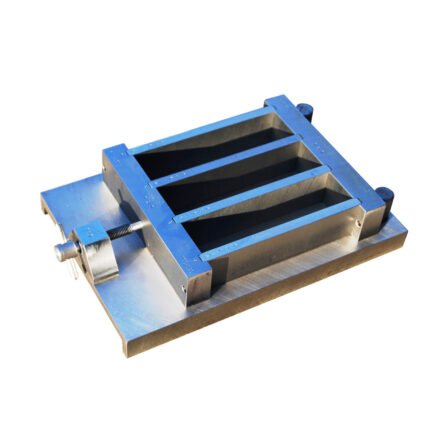

AZA 0808 PRISM MOULD THREE GANG

AZA 0811 VIBRATING MACHINE

IS4031 1968, IS1344 1959, BS 4550. Concrete moulds are easily cast by using a tamping bar or a vibrating table. However air trapped in cement mortar paste cannot be thus removed while casting cement mortar moulds. Easy method is to impart greater vibrating of lesser amplitude to the mould while casting This is achieved in a vibrating machine. Vibrating machine is used for the preparing of mortar cubes for the determination of compression strength of ordinary and rapid hardened Portland cement, low heat Portland cement, Portland blast furnace cement and high alumina cements.

Specification:

The machine consists of a vibrating frame assembly and an electric motor mounted on a sturdy base. The complete frame assembly consists of a vice to hold a 70.6 mm cube mould and two studs threaded at top and a hopper to feed the sample in the mould. This assembly is supported on four springs and has an in built rotating shaft which rotates eccentrically and thus imparts vibrations to the entire frame. A balance weight is an integral bottom part of the frame. The center of gravity of the assembly is brought to the centre of the eccentric shaft within a distance of 25 mm below it. The electric motor drives the shaft of the frame and thus imparts required vibration to the moulds.

The frequency of vibration is 12000 +/- 400 Vibration Per Minute. Supplied complete with on 70.6 mm Cube Mould with loose base plate, a time switch 0-5mins x 1mm.

Spares: Set of springs, belt and belt guard. Optional: Digital Preset Timer can be supplied at an extra cost.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items