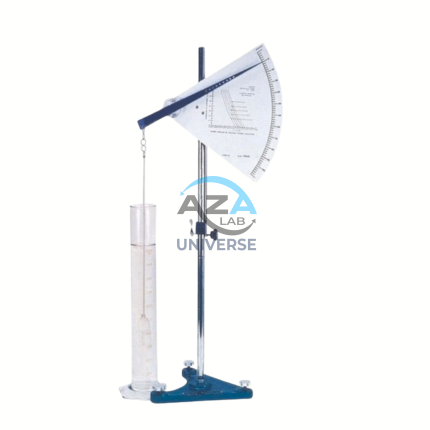

LABORATORY VANE SHEAR APPARATUS (MOTORISED) AZA0920

The AZA0920 Motorised Laboratory Vane Shear Apparatus from Azalab is a high-precision instrument designed for accurate determination of undrained shear strength (cᵤ) and sensitivity of cohesive soils such as clays and silts. The motorised drive ensures a constant and uniform rate of vane rotation, eliminating operator-induced variability and delivering highly repeatable, standard-compliant results.

This apparatus is an essential tool for geotechnical laboratories, research institutions, and civil engineering projects, particularly where reliable strength parameters of soft to medium cohesive soils are required for foundation, slope, and embankment design

Description

Principle of Operation

The laboratory vane shear test is a direct shear method performed on undisturbed or remoulded soil samples under controlled conditions:

-

A cruciform vane of standard dimensions is carefully inserted into the soil specimen.

-

The motorised drive applies torque at a constant prescribed rate.

-

The torque required to cause shear failure of the soil is measured using a calibrated torsion spring system.

-

The peak torque value is converted into undrained shear strength (cᵤ) using standard equations based on vane geometry.

-

After remoulding the soil by rapid rotation, a second test determines remoulded strength.

-

Soil sensitivity is calculated as the ratio of undisturbed to remoulded shear strength.

Applications

The AZA0920 is widely used for:

-

Determination of undrained shear strength of cohesive soils

-

Sensitivity evaluation of clays

-

Foundation and embankment design studies

-

Stability analysis of slopes and earth structures

-

Academic research and soil mechanics laboratories

-

Quality control in geotechnical investigations

Key Features and Advantages

-

Motorised rotation for constant and standard-compliant shear rate

-

High accuracy and repeatability compared to manual systems

-

Calibrated torsion spring torque measurement

-

Multiple interchangeable springs for different soil strength ranges

-

Adjustable vane head for precise insertion with minimal disturbance

-

Supplied with standard cruciform vanes

-

Robust laboratory-grade construction

-

Optional digital torque readout available

-

Supplied in a sturdy wooden carrying case

Standards Compliance

-

IS 2720 (Part 30): 1980 (Reaffirmed 2021) – Laboratory Vane Shear Test

-

ASTM D4648 / D4648M – Laboratory Miniature Vane Shear Test

-

BS 1377 – Part 7 – Shear Strength Tests

Specifications

| Parameter | Specification |

|---|---|

| Model | AZA0920 |

| Product Type | Laboratory Vane Shear Apparatus |

| Operation | Motorised |

| Power Supply | 230 V AC, Single Phase |

| Rotation Rate | Constant rate, typically 1/60 RPM (as per standards) |

| Torque Measurement | Calibrated torsion spring system |

| Springs Supplied | Set of 4 calibrated springs (various torque ranges) |

| Readout | Graduated dial with peak value pointer |

| Vane Head | Height adjustable via lead screw |

| Vane Blades | Standard cruciform vanes (multiple sizes supplied) |

| Sample Container | Suitable for prepared samples / sampling tubes |

| Construction | Heavy-duty steel |

| Accessories Included | Springs set, vane set, sample container, calibration chart, wooden carrying case |

| Standards | IS 2720 (Part 30), ASTM D4648, BS 1377-7 |

| Country of Origin | Made in India |

Frequently Asked Questions (FAQ)

Q1: What does the AZA0920 measure?

It measures the undrained shear strength and sensitivity of cohesive soils in laboratory conditions.

Q2: Why is motorised operation important?

A constant rotation rate is mandatory for accurate vane shear testing. Motorised operation ensures compliance with standards and eliminates operator variability.

Q3: Which soils can be tested?

Soft to medium cohesive soils such as saturated clays and silts. It is not suitable for sands or gravels.

Q4: Can both undisturbed and remoulded samples be tested?

Yes. The apparatus supports both, enabling sensitivity determination.

Q5: What vane sizes are provided?

A set of standard cruciform vanes of different dimensions is supplied to suit various soil strengths and standards.

Additional information

| Model |

AZA 0920 |

|---|---|

| Product Type |

Laboratory Vane Shear Apparatus |

| Operation |

Motorized (Electrically operated) |

| Power Supply |

230 V A.C., Single Phase |

| Rotation Rate |

Constant rate of rotation, typically 1/60 R.P.M. (or 0.1 degrees per second) as per standards. |

| Vane Head Assembly |

Adjustable height via lead screw and drive wheel for precise lowering of vane. |

Related products

LIQUID LIMIT DEVICE WITH COUNTER AZA0853

The AZA0853 Liquid Limit Device with Counter from AZALAB is a precision-engineered instrument used for determining the liquid limit of soils in accordance with the Casagrande method. This test is a fundamental component of soil classification and geotechnical investigation, providing critical insight into the plasticity, compressibility, and shear strength of fine-grained soils.

Designed for reliable, repeatable, and standardized testing, the AZA0853 is widely used in geotechnical laboratories, civil engineering departments, construction quality control labs, and academic institutions.

Principle of Liquid Limit Test (Casagrande Method)

The liquid limit is defined as the water content at which soil transitions from a plastic state to a liquid state. In practice, it is determined as the moisture content at which a standard groove cut in the soil sample closes over a length of 12.5 mm under 25 blows of the liquid limit apparatus.

The AZA0853 consists of a polished brass cup mounted on an adjustable bracket. The cup is repeatedly raised and dropped from a fixed height of 1 cm onto a hard rubber base by means of a manually operated cam mechanism. A built-in mechanical counter accurately records the number of blows, ensuring compliance with testing standards and reducing operator error.

PLASTIC LIMIT SET AZA0848

- Soil classification (Atterberg limits)

- Assessing workability and consistency

- Evaluating shrink–swell characteristics

- Supporting foundation, pavement, and earthwork design

PLUMMET BALANCE AZA0862

PROCTOR NEEDLES (SPRING TYPE) AZA0868

- Field assessment of soil compaction

- Estimation of optimum moisture condition

- Subgrade, fill, and trench inspection

- Construction quality control checks

- Geotechnical and educational field investigations

SAND EQUIVALENT TEST SET AZA0859

SOIL HYDROMETER AZA0858

STANDARD COMPACTION TEST AZA0864

The AZA0864 Standard Compaction Test Apparatus from Azalab is precision-engineered to perform the British Standard Proctor (Light Compaction) Test, as specified in BS 1377-4 and BS 1924-2. This apparatus is used to determine the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC) of soils subjected to light compactive effort.

The test simulates field compaction achieved by light rollers and rammers and is essential for quality control of subgrades, embankments, road bases, and foundation soils. The AZA0864 is widely used in geotechnical laboratories, site investigation works, and academic institutions following British Standards.

WATER LEVEL INDICATOR AZA0871

The AZA0871 Water Level Indicator from Azalab is a high-precision electronic instrument designed for accurate measurement of groundwater levels in boreholes, wells, standpipes, and observation tubes. It is an essential tool for professionals involved in groundwater monitoring, environmental site assessments, hydrological investigations, geotechnical projects, and dewatering operations.

Accurate water level measurement is fundamental for understanding aquifer behavior, monitoring seasonal or pumping-induced fluctuations, assessing contamination plumes, and supporting the design of foundations, irrigation systems, and water resource management plans. The AZA0871 provides a reliable, fast, and field-ready solution for both static and dynamic water level measurements.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items