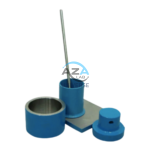

AGGREGATE IMPACT TESTER WITH BLOW COUNTER AZA0983

The AZA0983 Aggregate Impact Tester with Digital Blow Counter is a precision-engineered laboratory apparatus used to determine the Aggregate Impact Value (AIV) of coarse aggregates. It is designed to evaluate the toughness and resistance of aggregates used in road pavements, highways, and structural concrete.

This equipment is manufactured for durability, accuracy, and long service life, and is fully compliant with IS:2386 (Part IV) and BS 812 standards.

Key Features

-

Determines Aggregate Impact Value (AIV) for pavement materials

-

Integrated digital blow counter for accurate strike counting

-

Conforms to IS:2386 (Part IV) and BS 812

-

Heavy-duty, vibration-resistant frame

-

Cylindrical steel cup and standard impact hammer

Description

Purpose of the Test

The AIV test measures the resistance of aggregates to sudden impact or shock loads. This is crucial for understanding how aggregates will perform under repeated traffic loads and heavy vehicle movement.

Lower AIV values indicate stronger and more durable aggregates suitable for:

-

Highway roads

-

Airport runways

-

Industrial pavements

Working Principle

A prepared aggregate sample is placed inside a hardened steel cylindrical cup. A standard impact hammer (13.5–14 kg) is dropped freely from a height of 380 mm.

The built-in digital blow counter accurately records each strike. Standard testing involves 15 blows. After testing, the crushed material is sieved and the percentage of fines is used to calculate the Aggregate Impact Value (AIV %).

Included Components

-

Cylindrical Steel Cup

-

Impact Hammer

-

Guide Rod Assembly

-

Digital Blow Counter

-

Heavy Cast-Iron Base Frame

Applications

-

Highway and road material testing

-

Civil engineering laboratories

-

University and research institutions

-

Asphalt and RMC plants

-

Construction QA/QC departments

Technical Specifications

| Parameter | Details |

|---|---|

| Model No. | AZA0983 |

| Standard Compliance | IS:2386 (Part IV), BS 812 |

| Hammer Weight | 13.5 – 14 kg |

| Drop Height | 380 ± 5 mm |

| Blow Counter | Digital (LED Display) |

| Cup Material | Hardened Steel |

| Base Frame | Cast iron with anti-vibration mounts |

| Power Supply | 220V AC |

| Approx. Weight | 45–50 kg |

FAQ

Q1: What is this apparatus used for?

It is used to determine the Aggregate Impact Value (AIV) of coarse aggregates.

Q2: Why is the blow counter important?

It ensures accurate and consistent counting of hammer strikes during the test.

Q3: How many blows are applied in the test?

15 standard blows as per IS and BS standards.

Q4: Does it require frequent calibration?

Only the digital counter requires periodic checking; the mechanical parts are low maintenance.

Q5: Can this be used at construction sites?

Yes, it is suitable for both laboratory and field-level quality control.

Related products

ACCELERATED POLISHING MACHINE AZA0984

Key Features

- Tests polished stone value (PSV) of road aggregates

- Conforms to ASTM D3319 and BS 812 Part 114

- Heavy-duty rotating disc with abrasive feed system

- Integrated water spray system to simulate wet road conditions

- Powder-coated steel body for corrosion resistance

AVERAGE LEAST DIMENSION AZA0976

Key Features

- Measures flakiness index of coarse aggregates

- Fully compliant with IS 2386 (Part I) standards

- Precision steel frame with clearly labeled slots

- Easy-to-use, manual operation for rapid testing

- Heavy-duty, corrosion-resistant construction

- Suitable for laboratory and field environments

DEVEL ATTRITION TESTER AZA0989

Key Applications

- Road and highway material testing

- Railway ballast quality assessment

- Concrete mix design durability testing

- Civil engineering research & academic laboratories

DORRY ABRASION TESTING MACHINE AZA0988

Key Functions

- Evaluates abrasion and wear resistance of aggregates

- Simulates real-life mechanical rubbing and surface wear

- Ensures quality control for construction materials

- Supports research and teaching in civil engineering labs

FLAKINESS SIEVE SET AZA0973

The AZA0973 Flakiness Sieve Set is a laboratory-grade testing instrument designed to determine the flakiness index of coarse aggregates. It is an essential tool for evaluating aggregate particle shape, helping ensure strength, durability, and performance of concrete and road construction materials. This system is manufactured for full compliance with IS 2386 (Part I) and is widely used in civil engineering laboratories and construction quality control sites.

Key Features

-

Used for determining flakiness index of coarse aggregates

-

Fully compliant with IS 2386 (Part I) standards

-

Precision-machined slotted gauges for multiple aggregate sizes

-

Heavy-duty stainless steel / powder-coated steel construction

-

Corrosion-resistant, long service life

-

Portable and easy to use in lab and field environments

GRID SIEVES AZA0972

The AZA0972 Grid Sieves are heavy-duty screening tools designed for rapid particle size classification of coarse soils and aggregates. These sieves are ideal for quick, visual separation of gravel, crushed stone, and coarse sands in civil engineering, geotechnical, and construction materials laboratories. Their rugged construction makes them suitable for both laboratory and field applications.

Key Features

-

Designed for fast classification of coarse particles

-

Suitable for soil and aggregate testing

-

Heavy-duty stainless steel / galvanized steel construction

-

Precision-welded square or rectangular grid openings

-

Corrosion-resistant, abrasion-resistant long life design

-

Compatible with standard manual and mechanical sieve shakers

Reid Vapor Pressure Tester AZA1321

- Floor-Standing Design with stainless-steel working table for strength and easy operation

- Digital Temperature Controller for precise and uniform water bath heating

- Dual High-Accuracy Pressure Gauges for reliable internal pressure readings

- Dual Vapor Bombs for simultaneous testing and increased productivity

- Rugged Construction for long-term laboratory and industrial use

TILE ABRASION TESTING MACHINE AZA0992

Purpose of Testing

This test determines the depth of wear (in mm) on the tile surface after a fixed number of revolutions under an abrasive load. It helps manufacturers, contractors, and consultants verify whether tiles meet durability requirements for high-traffic applications.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items