TIG Welding Machine AZA 1235

- TIG welding machine for precise, clean welds

- Dual voltage input (110V/220V) for flexibility

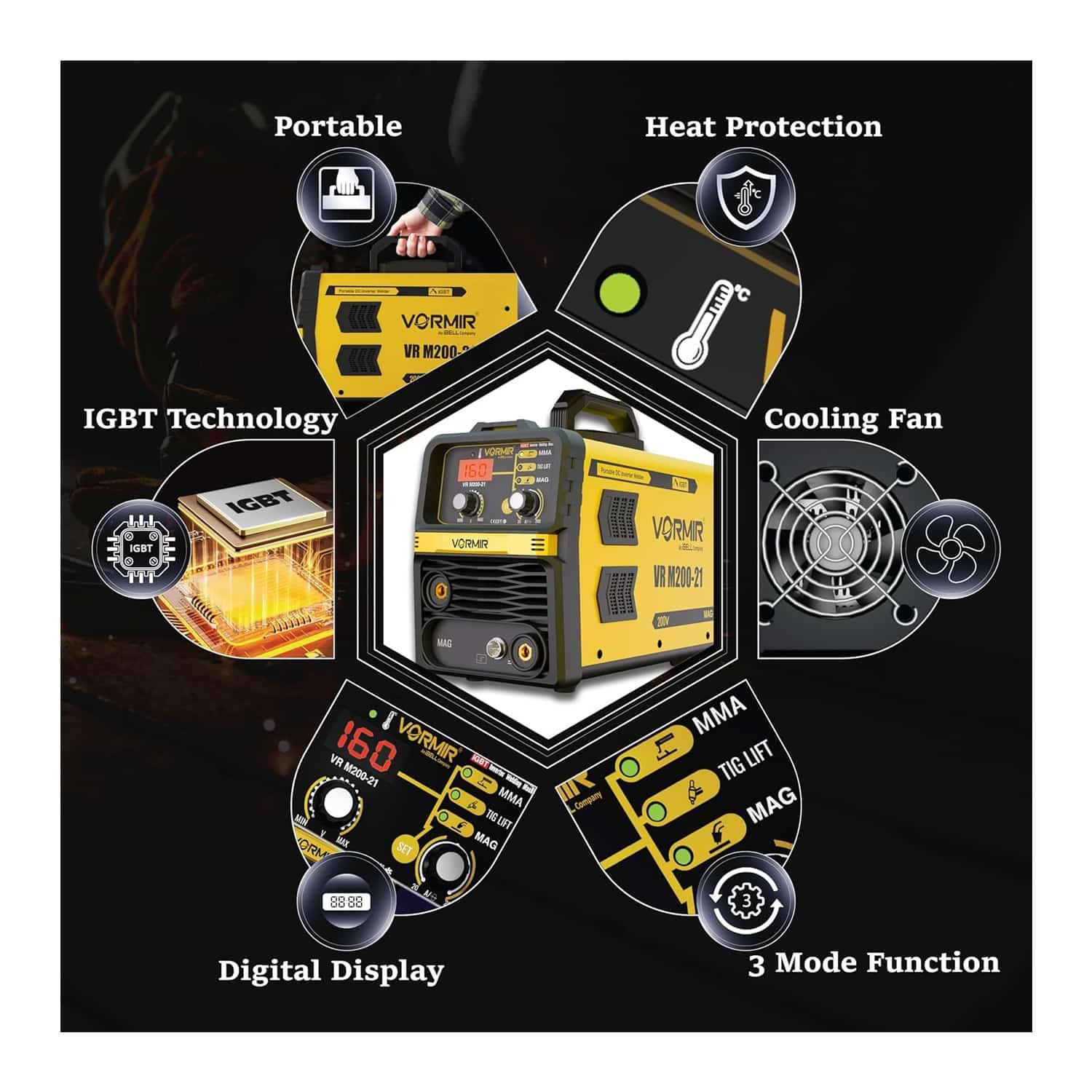

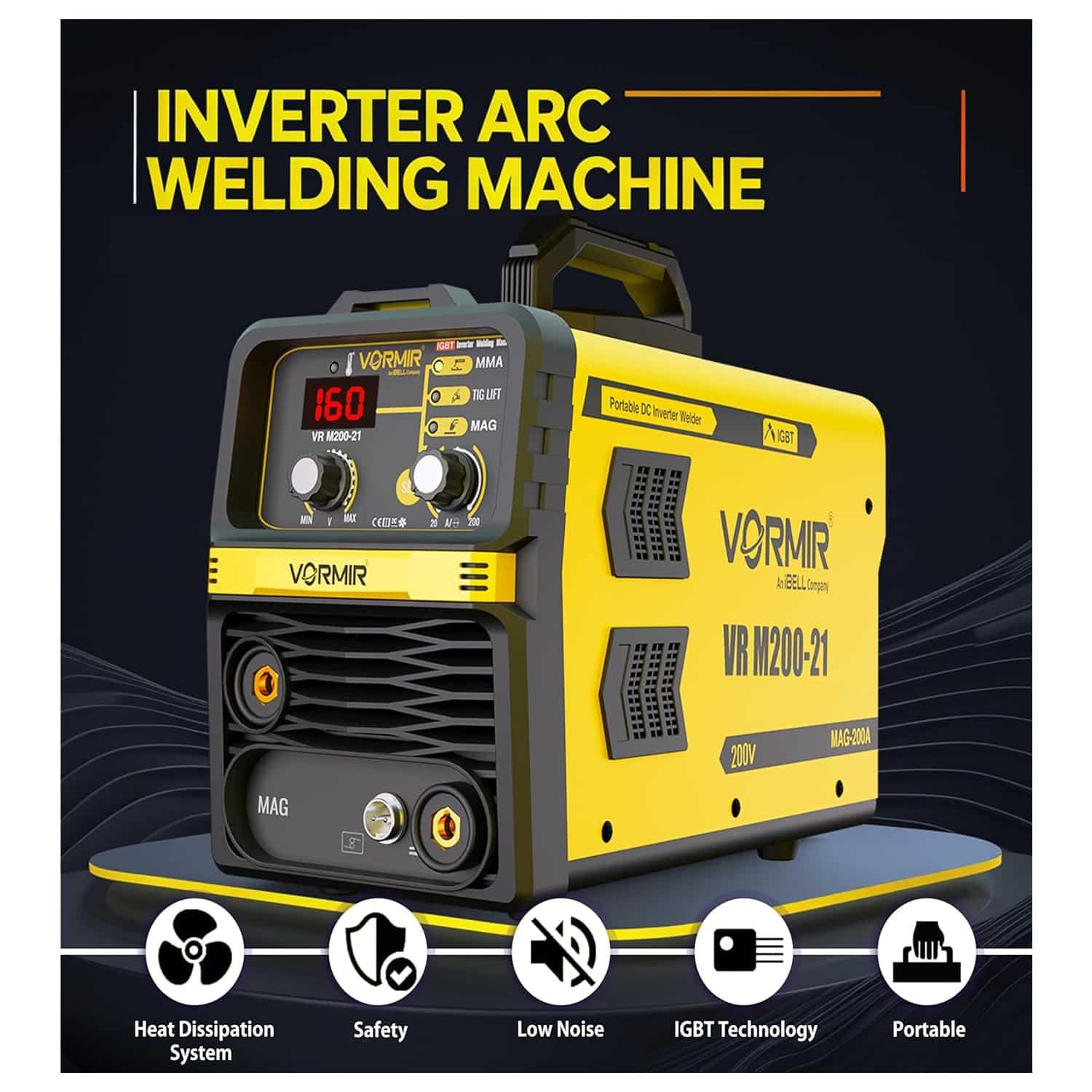

- Advanced IGBT inverter technology

- Digital LCD display for accurate settings

- Ideal for steel, stainless steel, and aluminum

- Overheat and overload protection

- Lightweight and portable for field use

- Model: AZA 1235 – designed for professional use

Description

TIG Welding Machine

TIG welding machine technology has become the go-to solution for welders requiring superior control, precision, and clean results. The AZA 1235 TIG Welding Machine from Azalab offers unmatched performance for both amateur and professional welders. Designed using advanced IGBT inverter technology, this welding unit brings high efficiency, energy savings, and long-term reliability to your fabrication workflow.

Whether you’re constructing fine metal art, repairing auto body parts, or building industrial frameworks, this precision welding tool ensures smooth arc control, minimal spatter, and neat finishes. Unlike traditional stick welders, TIG machines provide a stable, focused arc, making them perfect for thin materials and critical joints. The AZA 1235 takes this even further with its digital LCD interface for accurate amperage settings and real-time feedback during operation.

This model supports dual voltage (110V and 220V), offering flexibility for different power setups, whether you’re in a home garage or a commercial workshop. Its automatic voltage detection feature makes switching between inputs seamless. Users no longer have to worry about switching plugs or adjusting external voltage settings — just plug and weld.

The digital display enhances usability with clear readouts of current settings, especially useful during sensitive tasks where precision is paramount. The anti-stick, hot start, and soft start features further improve usability, reducing electrode sticking and allowing smooth arc initiation — ideal for beginners and professionals alike.

In terms of safety, the AZA 1235 is built with multiple protective mechanisms. It features overload protection, overcurrent safeguards, and thermal cut-off to ensure the internal components remain safe even during prolonged use. The built-in fan-on-demand cooling system activates only when required, reducing dust intake and extending the life of internal electronics.

Portability is another key advantage. Weighing just under 10 kg, the AZA 1235 is compact and easy to carry, thanks to its ergonomic handle and lightweight frame. This makes it an ideal companion for field operations, mobile repairs, or even for moving around different sections of a large workshop.

The welding torch, ground clamp, and accessories included in the package are of industrial-grade quality, ensuring long-lasting performance with minimal maintenance. The AZA 1235 is compatible with a variety of tungsten electrodes (typically 1.6mm to 3.2mm), and works optimally with Argon shielding gas, ensuring cleaner welds with stronger penetration.

TIG welding with this unit is not just about strength but also about aesthetics — weld beads are clean, even, and professional-looking. Whether you’re working with carbon steel, stainless steel, copper, or aluminum alloys, this machine delivers consistent results across the board.

To enhance your welding knowledge and explore advanced TIG techniques, you may refer to comprehensive technical guides available at industry-trusted sites like millerwelds.com or lincolnelectric.com, which provide global insights into welding standards, safety, and maintenance practices.

In conclusion, the TIG Welding Machine AZA 1235 is an all-in-one solution designed to meet the needs of modern welders. With advanced controls, a durable build, and intelligent safety features, it’s an excellent investment for workshops, construction sites, maintenance teams, and individual welders who demand precision and reliability. Backed by Azalab’s commitment to quality, the AZA 1235 is more than just a tool — it’s your welding partner.

Specifications:

| Feature | Specification |

|---|---|

| Model Number | AZA 1235 |

| Welding Type | TIG (Tungsten Inert Gas) |

| Input Voltage | Dual Voltage (110V / 220V) |

| Display | Digital LCD Screen |

| Technology | IGBT Inverter |

| Duty Cycle | 60% @ 200A |

| Electrode Compatibility | 1.6mm – 3.2mm |

| Gas Type | Argon (recommended) |

| Weight | Approx. 9.8 kg |

| Safety Features | Overload, Overheat, Overcurrent |

| Application | Steel, Stainless Steel, Aluminum |

| Cooling System | Fan-cooled |

Frequently Asked Questions (FAQ):

Q1: What materials can the TIG Welding Machine AZA 1235 weld?

A: It is ideal for welding stainless steel, aluminum, mild steel, and alloys.

Q2: Can this machine be used with household power?

A: Yes, the dual-voltage input supports both 110V and 220V, suitable for residential and industrial use.

Q3: Is it beginner-friendly?

A: Yes, the digital controls and stable arc make it user-friendly for both beginners and professionals.

Q4: Does it support pulse welding?

A: This model focuses on standard TIG operations and does not include pulse mode.

Q5: What safety features are included?

A: It comes with built-in overheat, overload, and overcurrent protection for safe operation.

Additional information

| Input Voltage |

220V ±10%, Single Phase, 50/60 Hz |

|---|---|

| Welding Current Range |

10A – 200A |

| Duty Cycle |

60% @ 200A |

| Welding Type |

TIG / MMA (Stick) Dual Mode |

You may also like…

Arc Welding Machine AZA1234

The AZA1234 Arc Welding Machine by A Z A Lab is a high-performance industrial welding solution engineered for demanding fabrication, maintenance, and structural welding applications. Designed using advanced inverter technology, this machine delivers superior arc stability, high efficiency, and reliable welding performance across a wide range of electrode types and materials.

With an inverter frequency of up to 20 kHz, the AZA1234 ensures fast dynamic response, reduced spatter, and excellent weld bead appearance. Its robust electrical design supports a high duty cycle, allowing continuous operation under heavy loads while maintaining consistent welding output—even with output cable lengths of up to 100 meters.

MIG Welding Machine AZA 1237

MIG Welding Machine AZA1236

The AZA LAB MIG Welding Machine – Model AZA1236 is a rugged and reliable welding solution engineered for demanding construction sites and industrial fabrication work. Designed to deliver a stable welding arc and consistent output, this machine ensures high-quality welds with minimal downtime and maintenance.

With a welding current range of 50–250 A, step-type voltage control, and 100% copper winding, the AZA1236 offers excellent efficiency, durability, and precise control, making it ideal for continuous welding operations in challenging environments.

MIG Welding Machine AZA1238

The AZA LAB MIG Welding Machine – Model AZA1238 is engineered for the most demanding industrial welding applications. Designed to deliver exceptional power, precision, and durability, this machine offers a high welding current range of 100–600 A, making it ideal for large-scale fabrication, heavy structural welding, and industrial manufacturing environments.

Built with a rugged construction and equipped with 100% copper winding, the AZA1238 ensures high electrical efficiency, stable arc characteristics, and long-term reliable performance even under continuous operation.

Spot Welding Machine AZA1242

The AZA LAB Spot Welding Machine – Model AZA1242 is a robust, precision-engineered machine designed for reliable and efficient spot welding applications. Built using high-grade copper strips and sections with an advanced water-cooling system, this machine ensures stable performance even under continuous operation and high thermal loads.

With accurate current control, flexible electrode actuation options, and a high operating speed of up to 60 spots per minute, AZA1242 is ideal for industrial welding environments requiring consistency, durability, and productivity.

Wire Butt Welding Machine AZA1244

The AZA LAB Wire Butt Welding Machine AZA1244 is a robust and energy-efficient solution designed for precise joining of wire ends in industrial environments. Engineered for durability and consistent performance, this machine is ideal for continuous operations under harsh working conditions. Its sturdy construction, automatic operation, and wide voltage compatibility make it a reliable choice for workshops, manufacturing units, and heavy-duty industrial applications.

With easy installation and low maintenance requirements, the AZA1244 ensures long service life while delivering stable and efficient welding performance.

Related products

AGGREGATE IMPACT TESTER WITH BLOW COUNTER AZA0983

The AZA0983 Aggregate Impact Tester with Digital Blow Counter is a precision-engineered laboratory apparatus used to determine the Aggregate Impact Value (AIV) of coarse aggregates. It is designed to evaluate the toughness and resistance of aggregates used in road pavements, highways, and structural concrete.

This equipment is manufactured for durability, accuracy, and long service life, and is fully compliant with IS:2386 (Part IV) and BS 812 standards.

Key Features

-

Determines Aggregate Impact Value (AIV) for pavement materials

-

Integrated digital blow counter for accurate strike counting

-

Conforms to IS:2386 (Part IV) and BS 812

-

Heavy-duty, vibration-resistant frame

-

Cylindrical steel cup and standard impact hammer

DIGITAL LOS ANGLES ABRASION TESTING MACHINE AZA0987

Key Functions

- Determines aggregate abrasion resistance under controlled test conditions

- Simulates real-life impact and wear suffered by aggregates

- Provides precise digital RPM and time control for repeatability

- Suitable for routine quality control and research laboratories

LOS ANGELES ABRASION TESTING MACHINE AZA0986

Key Functions

- Tests abrasion resistance of coarse aggregates

- Evaluates impact strength under repeated load cycles

- Ensures material suitability for roads, highways, and structural concrete

- Provides accurate, repeatable test results for quality control

Reid Vapor Pressure Tester AZA1321

- Floor-Standing Design with stainless-steel working table for strength and easy operation

- Digital Temperature Controller for precise and uniform water bath heating

- Dual High-Accuracy Pressure Gauges for reliable internal pressure readings

- Dual Vapor Bombs for simultaneous testing and increased productivity

- Rugged Construction for long-term laboratory and industrial use

SKID RESISTANCE AND FRICTION TESTER STANDARD AZA0985

The AZA0985 Skid Resistance & Friction Tester is a precision mechanical instrument designed to measure the coefficient of friction and skid resistance of pavement surfaces. Based on the pendulum operating principle, it accurately determines Skid Resistance Value (SRV) / British Pendulum Number (BPN) for both wet and dry surfaces.

This equipment is widely used by highway authorities, airport maintenance teams, civil engineering laboratories, and R&D institutions to ensure surface safety and compliance with international standards.

Key Features

-

Tests skid resistance of roads, runways & industrial floors

-

Conforms to ASTM E303 and BS 812 Part 114 standards

-

Fully mechanical pendulum system – no power required

-

Heavy-duty base with spring-loaded arm mechanism

-

Portable and field-friendly design

SPECIFIC GRAVITY AND WATER ABSORPTION OF AGGREGATES AZA0979

Key Features

- Comprehensive apparatus for specific gravity and water absorption testing

- Suitable for both fine and coarse aggregates

- Heavy-duty, corrosion-resistant construction

- High accuracy and repeatable results

- User-friendly configuration for lab and field use

THICKNESS GAUGE AZA0970

The AZA0970 Thickness Gauge is a precision measuring instrument designed for accurate thickness measurement of coatings, films, metals, plastics, rubbers, and painted surfaces. Engineered for laboratory and industrial applications, this compact and reliable device ensures consistent quality control, compliance with standards, and improved material performance across multiple industries.

Key Features

-

High-precision thickness measurement for laboratory and field use

-

Suitable for metals, films, plastics, rubber, and paint coatings

-

Available in analog dial and digital LCD display models

-

Lightweight, compact, and portable design

-

Fast response time with stable, repeatable readings

-

Easy zeroing and calibration mechanism

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items