APPARATUS FOR REACTIVITY OF QUICKLIME AZA0809

The AZA0809 Quicklime Reactivity Apparatus is a precision laboratory instrument engineered to measure the thermal reactivity of quicklime (CaO) when it reacts with water—a process known as slaking. This exothermic reaction produces heat, and by recording the temperature rise over time, the apparatus helps determine the quality, fineness, and reactivity rate of quicklime.

Widely used in lime processing plants, cement industries, construction materials testing labs, and research institutions, this apparatus ensures accurate evaluation of quicklime performance for applications in soil stabilization, water treatment, chemical manufacturing, and cement additives.

The apparatus fully complies with IS 1514:1990 – Methods of Sampling and Test for Quicklime and Hydrated Lime and ASTM C110 – Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone.

AUTOMATIC CEMENT COMPRESSION & FLEXURE TESTING MACHINES AZA0817

A dual-purpose, fully automated testing system designed to measure the compressive and flexural strength of cement cubes and prisms with high accuracy. Built to meet IS 516, IS 4031, ASTM C109, and ASTM C348 standards, it features an intelligent touchscreen controller, automatic loading, digital data storage, and a robust steel frame for long-term reliability. Ideal for cement plants, laboratories, and educational institutes requiring fast, precise, and repeatable cement strength testing

BENTONITE SLURRY SAMPLER 50 METERS AZA0813

The AZA0813 Bentonite Slurry Sampler from azalab is a robust, field-ready sampling device designed to obtain clean, uncontaminated samples of drilling slurry, bentonite mixes, grout, and cement-based slurries. Manufactured from high-quality white PVC, this sampler incorporates a double check-ball system that locks the slurry inside the chamber, preventing dilution or mixing with surrounding layers during retrieval.

With a 12-inch sample chamber and a 20-inch overall body length, the AZA0813 sampler is optimized for high-volume collection and smooth handling on construction, geotechnical, and foundation engineering sites. Its FDOT-approved design ensures compliance for critical QA/QC applications in diaphragm walling, piling, trenching, and drilling operations.aza

Lightweight yet durable, the PVC body resists corrosion, making it ideal for repeated field use and harsh job-site conditions.

- 5″ (88.9 mm) white PVC slurry sampler with double check-ball sealing

- FDOT-approved sampler for drilling fluid and bentonite slurry testing

- 12″ chamber length | 20″ total length for efficient field sampling

- Durable PVC construction with integrated lifting bail

- Suitable for bentonite, grout, drilling mud, and cement slurry collection

- Corrosion-resistant, lightweight, and easy to clean

BLAINE’S AIR PERMEABILITY APPARATUS AZA0787

BRIQUETTE MOULD (SINGLE) AZA0800

CEMENT SAMPLER AZA0786

FLOW CONE AZA0815

The AZA0815 Flow Cone Apparatus from azalab is a high-accuracy instrument used for determining the flowability, viscosity, and fluid consistency of cement grout, mortar, and fine aggregate mixtures. Designed to meet the requirements of ASTM C939 and IS 9103, it is an essential tool for quality control in civil engineering labs, ready-mix concrete plants, and on-site construction testing.

This apparatus—also referred to as a grout flow cone—helps evaluate the time required for a cementitious or fine aggregate mixture to flow through a calibrated orifice. This flow time directly correlates to the mix’s workability, fineness, fluidity, and performance in applications such as grouting, repair mortars, high-flow cement systems, and self-compacting materials.

Built from rust-resistant stainless steel or anodized aluminum, the AZA0815 Flow Cone provides long-term durability and easy cleaning. It is supplied complete with a funnel, powder-coated stand, and a calibration plate to verify orifice size and measurement accuracy.aza

Its simple design, quick operation, and repeatable results make it ideal for laboratory research, quality control departments, and field engineers dealing with high-flow grouts or fine slurry mixes.

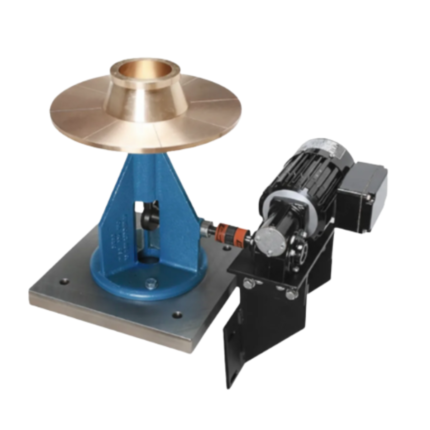

FLOW TABLE AZA0791

FLOW TABLE (MOTORISED) AZA0791 A

FLOW TABLE (MOTORISED) AZA0791C

Cement is one of the ancient raw materials used in construction.

It is uncertain where it was first discovered that a combination of hydrated non-hydraulic lime and a Poznan produces a hydraulic mixture (e.g., Portland cement) harden because of hydration chemical reactions that occur independently of the mixture’s water content; they can harden even underwater or when constantly exposed to wet weather.

Cement is essentially a binder that binds other materials together, Modern cements are manufactured by a chemical process.

Raw materials are crushed, ground and blended before being heated in a rotary kiln until they combine chemically. The clinker from the kiln is then ground with gypsum to form Portland cement.

Different types of cement with different strengths and characteristics can be produced depending on the composition and quality of clinker, fl y ash, silica

fume, retarders, water proffers, coloring agents and other additives used in the mix.

It is essential to test the physical and chemical parameters of each cement batch produced and to identify the unique characteristics of each composition.

Such parameters include specific surface and gravity of cement particles, consistency, soundness, setting time, heat of hydration, inorganic chemical analysis, loss on ignition, air content and strength.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items