BRINELL HARDNESS TESTER AZA1012

The AZA1012 Brinell Hardness Tester is a robust and reliable machine designed for precise measurement of Brinell Hardness (HBW) of metallic materials. It is widely used for testing steel, cast iron, aluminum, brass, copper, and alloys, especially where materials are non-homogeneous or have coarse grain structures.

Key Features – AZA1012

- Heavy-duty rigid metal body

- Mechanical / Hydraulic load application system

- Wide force range: 500 kgf to 3000 kgf

- Hardened steel / tungsten carbide ball indenters

- Optical microscope for indentation measurement

- Optional digital display system

- Adjustable dwell time

- High stability and long service life

CHARPY IMPACT TESTER AZA1013

The AZA1013 Charpy Impact Tester is a precision laboratory instrument designed to measure the impact strength and toughness of metallic materials. It evaluates a material’s ability to absorb energy during sudden fracture, helping identify brittle or ductile behavior under dynamic loading conditions.

Key Features – AZA1013

- Heavy-duty pendulum-type impact system

- Rigid cast-iron/steel frame for vibration-free operation

- Hardened steel hammer with precision knife edge

- Standard V-notch and U-notch specimen support

- Manual or optional automatic pendulum release

- Built-in safety brake and protective guard

- Low-friction bearings for accurate energy measurement

- Analog dial or optional digital energy display

DOUBLE DISC POLISHING MACHINE AZA1017

The AZA 1017 Double Disc Polishing Machine is a precision-engineered system designed for metallographic and materialographic surface finishing. It delivers scratch-free, mirror-like surfaces required for accurate microscopic examination. With its dual-disc configuration, it allows sequential polishing operations without changing discs, improving efficiency and workflow in laboratories.

Key Advantages

-

- Produces mirror-finish, scratch-free surfaces

- Dual polishing discs for faster, stepwise preparation

- Consistent and reproducible polishing results

- Reduces total specimen preparation time

- User-friendly and low-maintenance design

FATIGUE TESTING MACHINE AZA1014

The AZA1014 Fatigue Testing Machine is a high-precision system designed to evaluate a material’s resistance to cyclic and repeated loading. It helps predict service life, determine endurance limits, and prevent fatigue-related component failure in critical applications.

Key Features – AZA1014

- Precision cyclic load application system

- High-frequency testing capability

- Digital closed-loop control with real-time monitoring

- Advanced software for S-N curve generation and data analysis

- Automatic cycle counter with failure detection

- Interchangeable grips for axial, bending, and torsion tests

- Heavy-duty load frame for vibration-free performance

HYDRAULIC COMPUTERIZED UTM AZA1009

The AZA1009 Hydraulic Computerized UTM from Azalab is a heavy-duty, high-precision Universal Testing Machine designed for tensile, compression, bending, and shear testing of metals, concrete, composites, and structural materials. Powered by a servo-hydraulic loading system and advanced computerized control, it delivers accurate, repeatable, and reliable results for industrial, academic, and R&D applications.

Engineered for high-capacity testing, the AZA1009 is ideal for steel plants, infrastructure projects, automotive and aerospace labs, and quality control departments where large forces and precise control are essential.

Key Capabilities

- High-force hydraulic loading system for smooth and stable test execution

- Closed-loop servo control for load, displacement, and strain rate control

- Real-time PC-based data acquisition & graphing

- Automatic test sequencing and reporting

- Compatible with extensometers and strain measurement systems

METALLURGICAL INVERTED MICROSCOPE AZA1016

The AZA 1016 Metallurgical Inverted Microscope is a high-precision optical system designed for opaque material analysis. Its inverted design allows large and heavy samples to be placed directly on the stage, making it ideal for metals, alloys, ceramics, composites, and industrial components without the need for sectioning or special mounting.

Key Advantages

- Inverted optical system for easy sample placement

- Ideal for large, heavy, or irregular samples

- Stable viewing plane for uniform focusing

- Reflected (Epi) illumination for opaque materials

- Safe operation with reduced risk of objective damage

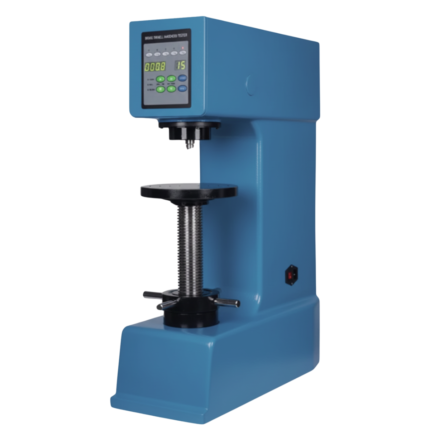

ROCKWELL HARDNESS TESTER AZA1011

The AZA1011 Rockwell Hardness Tester by Azalab is a robust, fast, and highly accurate benchtop hardness testing machine designed for measuring the hardness of metals and alloys. Built in accordance with IS, BS, ASTM, ISO, and DIN standards, this machine delivers direct, rapid, and repeatable hardness readings for production floors, workshops, laboratories, and research institutions.

Since 1966, Azalab hardness testers have been trusted for their simple operation, rugged construction, and high reliability, making AZA1011 ideal for both routine inspection and advanced material testing.

Testing Capabilities

The AZA1011 performs:- Rockwell Hardness Testing (HRA, HRB, HRC and other scales)

- Brinell Hardness Testing (on specific variants)

- Flat, round, tubular, and irregular metal samples

- Hard and soft metals

- Steel, cast iron, aluminum, brass, copper, and hardened alloys

SPECIMEN MOUNTING PRESS AZA1018

The AZA1018 Specimen Mounting Press is a robust, precision-engineered hot mounting machine designed for preparing metallographic samples by encapsulating them in thermosetting resin. It delivers void-free, strong, and uniformly shaped mounts, ensuring reliable results in subsequent grinding, polishing, and microscopic examination.

Key Advantages

-

- Produces defect-free, uniform mounts

- Protects fragile and irregular specimens

- Ensures excellent edge retention

- Reduces handling damage

- Improves repeatability in sample preparation

TENSILE TESTING MACHINE AZA1015

The AZA1015 Tensile Testing Machine is a precision Universal Testing Machine (UTM) designed for accurate measurement of mechanical properties of materials. It is ideal for testing metals, plastics, rubber, composites, and other solid materials under tensile load.

Key Features – AZA1015

-

- High-precision electronic load cell

- Servo-motor driven electromechanical system

- Digital / PC-controlled operation

- Variable crosshead speed for different materials

- Real-time stress–strain graph display

- Optional extensometer for accurate strain measurement

- Heavy-duty load frame for stable, repeatable results

TORSION TESTING MACHINE AZA1010

The AZA1010 Torsion Testing Machine by Azalab is a precision-engineered laboratory system designed to evaluate the behavior of materials under twisting (torsional) loads. It accurately determines torsional strength, shear modulus (modulus of rigidity), yield strength in shear, and ductility in torsion, making it essential for industries where components experience rotational stress such as automotive, aerospace, medical device manufacturing, and spring production.This machine delivers highly reliable torque vs. angle of twist data and supports both research and quality control applications.

Working Principle

The AZA1010 applies a controlled rotational force (torque) to a securely clamped specimen:- One end of the specimen is fixed to a precision torque transducer

- The opposite end is rotated by a motorized drive system

- The system simultaneously measures:

- Applied Torque

- Angle of Twist (angular deformation)

Steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). By far the most widely used material for building the world’s infrastructure and industries, it is used to fabricate everything from sewing needles to oil tankers.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items