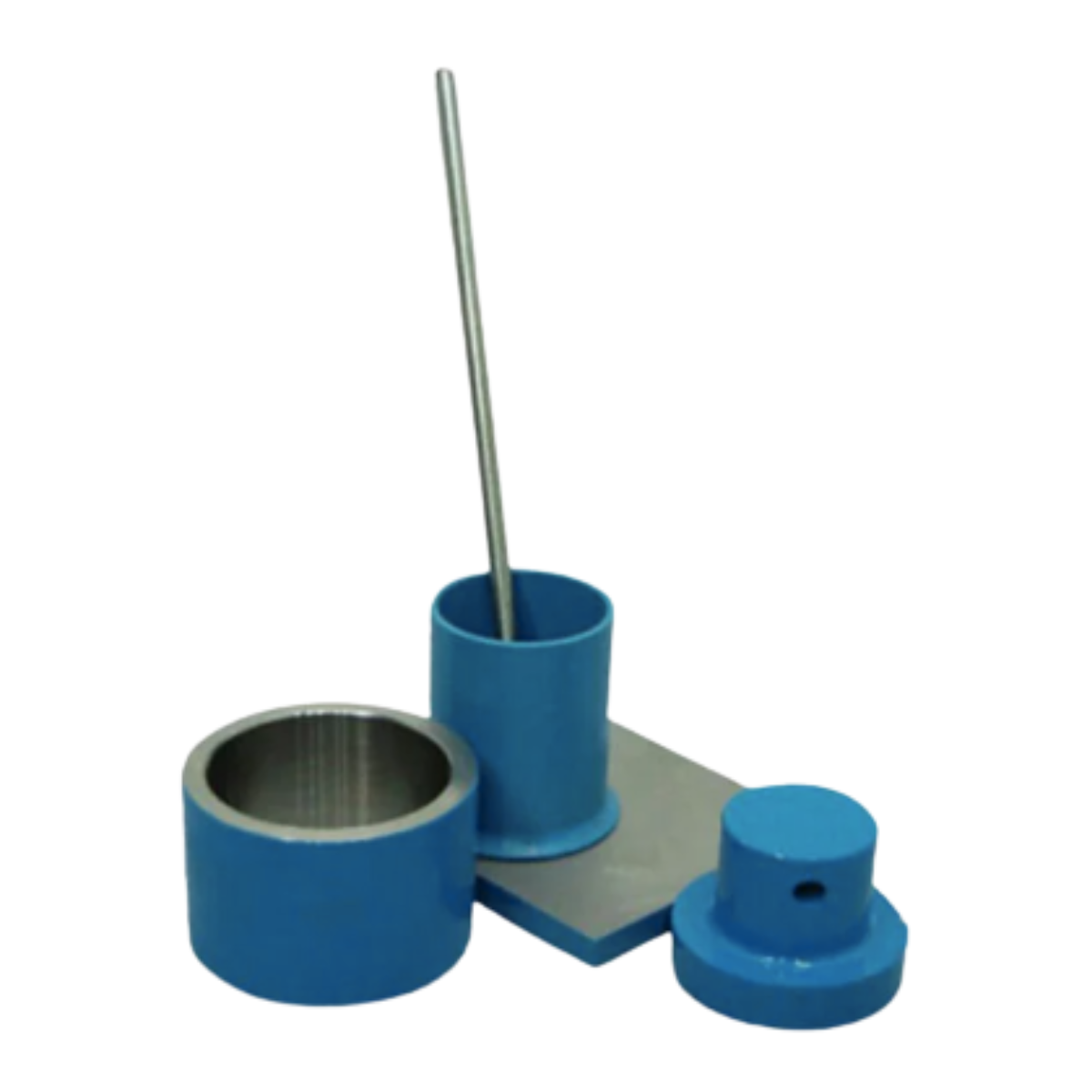

AGGREGATE CRUSHING VALUE APPARATUS AZA0982

The AZA0982 Aggregate Crushing Value (ACV) Apparatus is a heavy-duty laboratory testing system used to determine the crushing strength of coarse aggregates. It is designed for standard compliance testing required in road construction, concrete production, and civil engineering quality control.

Manufactured with precision-machined components, this apparatus delivers consistent, accurate, and repeatable results in accordance with IS:2386 (Part IV) and BS 812 standards.

Key Features

- Measures crushing strength of coarse aggregates

- Conforms to IS:2386 (Part IV) and BS 812 standards

- Precision-machined steel cylinder and plunger

- Heavy-duty, corrosion-resistant construction

- Supplied with complete accessories for immediate testing

Description

Purpose of Test

The Aggregate Crushing Value (ACV) test determines the resistance of aggregate material to crushing under gradually applied compressive load. This is critical to ensure that aggregates used in:

-

Road pavements

-

Airport runways

-

Concrete structures

-

Railway ballast

can withstand heavy traffic loads and environmental stress.

A lower ACV percentage indicates stronger, more durable aggregates.

Working Principle

A known weight of dry aggregate is placed into a steel cylindrical mold and compacted using a tamping rod. A plunger is then inserted, and the assembly is placed in a compression testing machine where a load (typically up to 40 tons) is applied.

After loading, the crushed material is sieved through a 2.36 mm sieve, and the percentage of fines is calculated using:

ACV (%) = (Weight of fines / Original sample weight) × 100

Included Components

-

Steel Cylinder (150 mm internal diameter × 130 mm height)

-

Precision Steel Plunger (148 mm diameter)

-

Rigid Base Plate

-

Standard Tamping Rod (16 mm Ø × 600 mm length)

-

Metal Measure

Note: Compression testing machine is supplied separately.

Applications

-

Highway and road material quality control

-

Concrete and construction aggregate testing

-

Railway ballast strength evaluation

-

Civil engineering research and teaching

-

Government and private testing laboratories

Technical Specifications

| Parameter | Details |

|---|---|

| Model No. | AZA0982 |

| Standard Compliance | IS:2386 (Part IV), BS 812 |

| Cylinder Size | 150 mm ID × 130 mm Height |

| Plunger Diameter | 148 mm |

| Base Plate | Heavy-duty cast iron |

| Material | Powder-coated mild steel |

| Accessories | Plunger, tamping rod, metal measure |

| Approx. Weight | 30–40 kg |

FAQ

Q1: What is the purpose of this apparatus?

It is used to determine the crushing strength of aggregates under compressive load.

Q2: Does this include the compression testing machine?

No, the compression testing machine is supplied separately.

Q3: What is an acceptable ACV value for road construction?

An ACV value below 30% is typically preferred for high-load road surfaces.

Q4: Can it be transported to site?

Yes, it is robust yet portable enough for site laboratory use.

Q5: Which standards does it comply with?

It complies with IS:2386 (Part IV) and BS 812 standards.

Related products

ACCELERATED POLISHING MACHINE AZA0984

Key Features

- Tests polished stone value (PSV) of road aggregates

- Conforms to ASTM D3319 and BS 812 Part 114

- Heavy-duty rotating disc with abrasive feed system

- Integrated water spray system to simulate wet road conditions

- Powder-coated steel body for corrosion resistance

CYLINDRICAL MEASURES AZA0977

The AZA0977 Cylindrical Measures are precision laboratory containers designed for determining the bulk density (unit weight) and void ratio of fine and coarse aggregates. These measurements are essential for quality control in concrete mix design, highway construction, and geotechnical investigations. Manufactured by Azalab, these measures fully comply with IS 2386 (Part III), ASTM C29, and BS 812 standards.

Key Features

-

Used for measuring bulk density and void ratio of aggregates

-

Available in standard capacities: 3L, 5L, and 15L

-

Heavy-duty mild steel / aluminum construction

-

Smooth, accurately machined internal surfaces

-

Supplied with tamping rod and leveling accessories

-

Corrosion-resistant, long-life surface finish

-

Easy-grip handles for portability

DEVEL ATTRITION TESTER AZA0989

Key Applications

- Road and highway material testing

- Railway ballast quality assessment

- Concrete mix design durability testing

- Civil engineering research & academic laboratories

DIGITAL LOS ANGLES ABRASION TESTING MACHINE AZA0987

Key Functions

- Determines aggregate abrasion resistance under controlled test conditions

- Simulates real-life impact and wear suffered by aggregates

- Provides precise digital RPM and time control for repeatability

- Suitable for routine quality control and research laboratories

GRID SIEVES AZA0972

The AZA0972 Grid Sieves are heavy-duty screening tools designed for rapid particle size classification of coarse soils and aggregates. These sieves are ideal for quick, visual separation of gravel, crushed stone, and coarse sands in civil engineering, geotechnical, and construction materials laboratories. Their rugged construction makes them suitable for both laboratory and field applications.

Key Features

-

Designed for fast classification of coarse particles

-

Suitable for soil and aggregate testing

-

Heavy-duty stainless steel / galvanized steel construction

-

Precision-welded square or rectangular grid openings

-

Corrosion-resistant, abrasion-resistant long life design

-

Compatible with standard manual and mechanical sieve shakers

JAW CRUSHER AZA0990

Key Applications

- Crushing of rocks, minerals & hard aggregates

- Soil and geotechnical laboratories

- Cement plants and construction R&D labs

- Pre-processing for pulverisers and sieve shakers

- Mining and metallurgical laboratories

SKID RESISTANCE AND FRICTION TESTER STANDARD AZA0985

The AZA0985 Skid Resistance & Friction Tester is a precision mechanical instrument designed to measure the coefficient of friction and skid resistance of pavement surfaces. Based on the pendulum operating principle, it accurately determines Skid Resistance Value (SRV) / British Pendulum Number (BPN) for both wet and dry surfaces.

This equipment is widely used by highway authorities, airport maintenance teams, civil engineering laboratories, and R&D institutions to ensure surface safety and compliance with international standards.

Key Features

-

Tests skid resistance of roads, runways & industrial floors

-

Conforms to ASTM E303 and BS 812 Part 114 standards

-

Fully mechanical pendulum system – no power required

-

Heavy-duty base with spring-loaded arm mechanism

-

Portable and field-friendly design

TIG Welding Machine AZA 1235

- TIG welding machine for precise, clean welds

- Dual voltage input (110V/220V) for flexibility

- Advanced IGBT inverter technology

- Digital LCD display for accurate settings

- Ideal for steel, stainless steel, and aluminum

- Overheat and overload protection

- Lightweight and portable for field use

- Model: AZA 1235 – designed for professional use

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items