IMPALEMENT SAFETY COVERS AZA1023

Rebar Protection Solutions for Construction Site Safety & Compliance by Azalab

AZA1023 Impalement Safety Covers are critical safety components designed to protect workers, visitors, and pedestrians from impalement hazards caused by exposed reinforcement bars (rebars) on construction sites. These covers significantly reduce the risk of serious injury or fatal accidents while helping projects comply with mandatory safety regulations such as OSHA, BIS, and international construction safety standards.

At Azalab, safety is engineered into every detail. The AZA1023 range is developed to deliver high impact resistance, excellent visibility, easy installation, and long service life, making it an essential safety accessory for residential, commercial, and large-scale infrastructure projects

Description

Why Use Impalement Safety Covers?

Unprotected vertical or horizontal rebars present one of the most severe hazards on construction sites. Slips, falls, or accidental contact can turn exposed steel rods into life-threatening spikes. Using certified impalement safety covers is a proven and widely mandated method to mitigate this risk.

AZA1023 Impalement Safety Covers provide a physical barrier that disperses impact energy and prevents direct contact with sharp rebar ends.

Key Features & Benefits

-

High-Impact Resistance

Manufactured from industrial-grade plastic, rubber, or steel-reinforced polymer capable of absorbing impact forces. -

High Visibility Colors

Supplied in bright orange, yellow, or red for easy identification by workers and safety inspectors. -

Universal Fit

Compatible with standard reinforcement bar sizes including 8 mm, 12 mm, 16 mm, 20 mm, 25 mm, and up to 32 mm. -

Tool-Free Installation

Simple push-on design allows quick installation and removal without tools. -

Weather & UV Resistant

Designed to perform reliably in heat, rain, dust, and prolonged outdoor exposure. -

Reusable Options Available

Heavy-duty rubber and reinforced models can be reused across multiple project phases.

Types of AZA1023 Impalement Safety Covers

-

Flat Safety Caps

Basic protection and visual warning; suitable for low-risk or short-duration exposure. -

Mushroom Head Safety Caps

Enlarged head distributes impact force and offers improved impalement protection. -

Steel Plate Reinforced Caps

Heavy-duty protection with internal steel plate; recommended for high-rise and high-risk zones. -

Reusable Heavy-Duty Covers

Designed for long-term use and repeated installation cycles.

Typical Applications

-

High-Rise Construction – Vertical rebars on slabs and columns

-

Bridge & Flyover Projects – Exposed rods during deck and pier works

-

Foundations & Footings – Starter bars emerging from concrete bases

-

Roads, Tunnels & Infrastructure – Rebars near traffic or pedestrian zones

-

Residential & Commercial Sites – Ensures safety compliance throughout construction phases

Installation Guidelines

-

Clean the exposed rebar to remove dust, oil, or concrete residue

-

Select the appropriate AZA1023 cover based on rebar diameter

-

Push the safety cover firmly onto the bar end

-

Ensure a snug fit that cannot be easily dislodged

-

Inspect covers periodically and replace damaged units

For rebars exceeding 1 meter in height or in elevated work zones, steel-reinforced caps are strongly recommended.

Safety Standards & Compliance

-

OSHA 1926.701(b) – Mandatory protection of exposed reinforcement steel

-

IS 15877:2023 (India) – Construction site safety guidelines

-

Compatible with EN ISO standards for site access and safety systems

Technical Specifications

| Attribute | Details |

|---|---|

| Model | AZA1023 |

| Material | Plastic / Rubber / Steel-Reinforced Polymer |

| Color Options | Orange, Yellow, Red |

| Rebar Compatibility | 8 mm – 32 mm |

| Available Types | Flat Cap, Mushroom Head, Reinforced Plate |

| Reusability | Yes (select models) |

| Operating Temperature | -10°C to 60°C |

| Standards Compliance | OSHA, BIS, EN ISO |

| Installation Method | Manual push-on |

Frequently Asked Questions (FAQ)

Q1: Are AZA1023 impalement safety covers reusable?

Yes. Heavy-duty plastic and rubber variants are designed for multiple reuse cycles.

Q2: Do these meet statutory safety requirements?

Yes. All AZA1023 covers comply with OSHA and BIS construction safety norms.

Q3: Are they suitable for long-term outdoor exposure?

Yes. UV-stabilized materials ensure durability in harsh outdoor conditions.

Q4: What rebar sizes are supported?

Standard models fit rebars from 8 mm to 32 mm. Custom sizes are available on request.

Q5: Do you offer bulk pricing?

Yes. Azalab provides special pricing for large projects, contractors, and safety suppliers.

AZA1023 – Key Highlights

-

Prevents impalement injuries from exposed rebars

-

Compliant with OSHA and BIS construction safety standards

-

High-impact plastic, rubber, or steel-reinforced construction

-

Tool-free installation on vertical and horizontal bars

-

Bright colors for high on-site visibility

-

Suitable for residential, commercial, and civil infrastructure projects

Additional information

| Material |

Plastic, Rubber, Steel-reinforced Poly |

|---|---|

| Colors Available |

Orange, Yellow, Red |

| Rebar Compatibility |

8 mm – 32 mm rebars |

| Types |

Flat Cap, Mushroom Head, Reinforced Plate |

You may also like…

Abrasion Testing Machine for Glazed Tiles AZA1262

The AZA LAB Abrasion Testing Machine for Glazed Tiles (AZA1262) is a robust, high-performance laboratory instrument engineered for precise and high-speed abrasion resistance testing of glazed ceramic tiles. Fully compliant with BIS 13630-11 and EN ISO 10545-7, this machine is designed to ensure reliable evaluation of tile durability under simulated real-world wear conditions.

With the capability to test up to four specimens simultaneously, the AZA1262 significantly improves testing efficiency while maintaining exceptional accuracy and repeatability—making it ideal for tile manufacturers, certification laboratories, and quality control departments

ABS Braking System Training Board Simulator AZA1245

The AZA1245 AZALAB ABS Braking System Training Board Simulator is a fully functional automotive training platform designed to provide in-depth, hands-on understanding of Anti-lock Braking System (ABS) operation, diagnostics, and repair procedures. Built using real automobile components, this simulator enables students and technicians to study ABS structure, electronic control, hydraulic behavior, and fault diagnostics in a safe and controlled learning environment.

This training system is ideal for automotive training institutes, engineering colleges, technical schools, and service technician programs, supporting both instructional demonstrations and practical troubleshooting exercises.

MARSH FUNNEL WITH MEASURING CUP AZA0811

The AZA0811 Marsh Funnel with Measuring Cup is a simple, reliable device used to determine the viscosity of drilling muds, bentonite slurries, cement slurries, and similar suspensions in both field and laboratory environments. It provides a fast and practical method to assess flow characteristics critical to drilling operations, soil stabilization, grouting, and geotechnical engineering.

The instrument includes a conical Marsh Funnel—manufactured from high-impact polypropylene or optional stainless steel—and a 1-liter graduated measuring cup. During the test, the time taken for 946 mL (1 US quart) of slurry to flow through the funnel orifice is recorded in seconds. This value serves as an index of slurry viscosity and is widely accepted in compliance with API RP 13B-1 and ASTM D6910 standards.

Related products

ALUMINUM TRIPOD AZA1037

AZA1037 Aluminum Tripod (Surveying & Construction Instrument Stand)

The AZA1037 Aluminum Tripod from Azalab is a high-precision, field-ready instrument stand engineered to provide maximum stability, portability, and durability for professional surveying and construction applications. It serves as a reliable mounting platform for auto levels, total stations, theodolites, rotary lasers, and mapping instruments, ensuring accurate measurements in demanding site conditions.

Lightweight & Corrosion-Resistant Construction

Manufactured from high-grade anodized aluminum alloy, the AZA1037 tripod offers an optimal balance between strength and weight. The corrosion-resistant finish makes it suitable for prolonged outdoor use, including dusty construction sites, uneven terrain, and damp environments, without compromising structural integrity or performance.

Despite its robust construction, the tripod remains lightweight, allowing easy handling and transportation between job locations.

ELECTRONIC THEODOLITE AZA1027

Precision Redefined for Field Surveying

The AZA1027 is an essential instrument for topographic surveys, construction layout, and structural alignment. Equipped with high-resolution angle encoders, it significantly reduces reading errors and ensures consistent measurement accuracy.

An integrated optical plummet and dual-axis compensator allow reliable operation even on uneven terrain. With angular accuracy ranging from ±2″ to ±5″ seconds (model dependent), the AZA1027 is ideal for projects requiring tight tolerances such as bridges, tunnels, and high-rise structures.

GEOLOGICAL HAMMER AZA1041

The Geological Hammer AZA1041 from Azalab is a robust, professional-grade field tool designed for rock sampling, mineral identification, fossil extraction, and geological exploration. It is an essential instrument for geologists, earth science students, archaeologists, mining professionals, and fossil enthusiasts, offering exceptional strength, balance, and reliability in demanding field conditions.

Engineered for rugged outdoor use, the hammer features a forged one-piece, heat-treated high-carbon steel head, ensuring superior impact resistance, long service life, and safety during repeated strikes. Unlike welded or cast alternatives, the forged construction prevents head separation and deformation, even when used on hard igneous or metamorphic rocks.

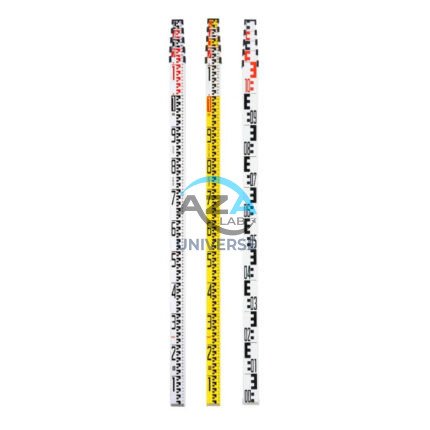

LEVELLING STAVES AZA1034

AZA1034 Levelling Staves (Survey Staff / Leveling Staff)

The AZA1034 Levelling Staff is an essential surveying accessory used in conjunction with dumpy levels, automatic levels, and digital levels to accurately measure height differences between ground points. Designed for reliability, visibility, and ease of handling, it is a critical tool for construction, civil engineering, and land surveying applications.

Accurate Elevation Measurement

Levelling staves provide a vertical reference that allows surveyors and engineers to determine elevation differences with precision. When viewed through an optical leveling instrument, the graduated scale on the AZA1034 enables clear and accurate readings, ensuring dependable height transfer across distances.

The staff is available with metric (cm/m) or imperial (ft/in) graduations, depending on project requirements.

SCAFFOLD POLY CLIP AZA1019

Secure Fastening Solution for Debris Netting & Protective Mesh by Azalab

AZA1019 Scaffold Poly Clips are essential construction safety accessories designed for the secure fastening of debris netting, shade mesh, and protective sheeting to scaffolding structures. Engineered for durability, safety, and ease of use, these clips provide a tool-free, reusable, and weather-resistant fixing solution for construction and industrial sites.

Widely used by builders, safety officers, scaffolding contractors, and site supervisors, AZA1019 clips help improve site safety, dust control, and environmental protection at height.

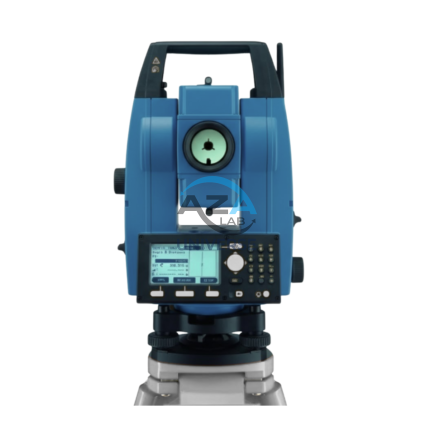

TOTAL STATION AZA1028

AZA1028 Total Station

The AZA1028 Total Station is a high-performance, all-in-one surveying instrument that integrates an electronic theodolite, electronic distance measurement (EDM), and advanced data recording into a single, robust platform. Designed for precision, efficiency, and durability, AZA1028 is an indispensable solution for civil engineers, construction professionals, land surveyors, and GIS specialists.

TOTAL STATION BUILDER AZA1029

AZA1029 Total Station Builder

The AZA1029 Total Station Builder is a high-precision digital surveying instrument engineered for construction layout, topographic surveying, and leveling applications. Combining an electronic theodolite, advanced EDM technology, and integrated survey software into a single rugged platform, AZA1029 delivers accuracy, efficiency, and reliability for demanding field environments.

Designed specifically for civil engineers, surveyors, and construction professionals, the AZA1029 ensures fast, repeatable, and highly accurate positioning across complex job sites.

WOODEN TRIPOD AZA1038

Superior Stability with Natural Vibration Dampening

Unlike aluminum tripods, wooden tripods provide natural vibration absorption, making them the preferred choice for total stations, theodolites, laser scanners, and auto levels—especially for long-distance and high-accuracy measurements. The AZA1038 is manufactured from seasoned hardwood, carefully selected and treated to resist moisture, warping, and deformation, ensuring consistent performance in both dry and humid environments

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items