Arc Welding Machine AZA1234

The AZA1234 Arc Welding Machine by A Z A Lab is a high-performance industrial welding solution engineered for demanding fabrication, maintenance, and structural welding applications. Designed using advanced inverter technology, this machine delivers superior arc stability, high efficiency, and reliable welding performance across a wide range of electrode types and materials.

With an inverter frequency of up to 20 kHz, the AZA1234 ensures fast dynamic response, reduced spatter, and excellent weld bead appearance. Its robust electrical design supports a high duty cycle, allowing continuous operation under heavy loads while maintaining consistent welding output—even with output cable lengths of up to 100 meters.

Description

Technology & Performance

The AZA1234 utilizes modern IGBT-based inverter technology, significantly reducing energy losses and improving overall efficiency. With a no-load loss of only 100 W, the machine operates economically while delivering high welding power when required.

An integrated Auto-Compensation Function automatically adjusts to fluctuations in input power supply, ensuring consistent arc performance and superior seam formation under unstable electrical conditions. This makes the machine highly adaptable to industrial environments and on-site operations.

Welding Capability

This arc welding machine is designed for maximum versatility, supporting a broad range of electrode types and welding positions. It is particularly effective for:

-

Low and medium carbon steel

-

Low alloy steel

-

Stainless steel

-

Structural and fabrication welding

The machine supports down-orientation welding with cellulose electrodes and performs reliably with various basic and rutile electrodes.

Operator Safety & Control

The AZA1234 includes a full-range anti-stick function, preventing electrode sticking and minimizing downtime during welding operations. This feature improves arc initiation, enhances operator control, and reduces electrode wastage.

Its stable output characteristics ensure smooth arc behavior, even at high currents, making it suitable for both precision welding and heavy-duty industrial applications.

Applications

-

Industrial fabrication workshops

-

Structural steel welding

-

Plant maintenance and repair

-

Heavy engineering projects

-

Construction and infrastructure welding

-

Training and industrial laboratories

Key Features

-

Advanced high-frequency inverter technology (up to 20 kHz)

-

High duty cycle for continuous industrial welding

-

Stable arc performance with long output cables (up to 100 m)

-

Auto-compensation for power supply fluctuations

-

Anti-stick function across full current range

-

Wide electrode compatibility including cellulose electrodes

-

Excellent seam shaping and arc stability

-

Energy-efficient operation with low no-load losses

Technical Specifications

| Parameter | Details |

|---|---|

| Model | AZA1234 |

| Supply Voltage | 415 VAC ±15% |

| Frequency | 50 / 60 Hz |

| Phase | 3 Phase |

| Input Power | 18.2 kVA |

| Rated Input Current | 27.6 A |

| Output Current Range | 40 – 400 A |

| Maximum Output Current | 400 A |

| Duty Cycle | 60% |

| Efficiency | 85% |

| Power Factor | 0.93 |

| No Load Voltage | 68 V |

| No Load Loss | 100 W |

| Housing Protection | IP21 |

| Dimensions (L × W × H) | 21.5 × 11 × 21.5 inches |

| Weight | 33 kg |

Product Highlights

-

High-power industrial arc welding machine

-

Reliable performance under fluctuating power conditions

-

Suitable for heavy-duty and continuous welding operations

-

Designed for professional fabrication and engineering use

-

Durable, efficient, and workshop-ready design

Model: AZA1234

Related products

Bandsaw Machine AZA1193

The AZA1193 Bandsaw Machine by AZALAB is a robust, high-precision cutting solution designed for efficient and accurate cutting of metal and wood materials in industrial workshops, fabrication units, and training laboratories. Engineered with a stress-relieved fabricated steel structure, the machine delivers excellent rigidity, vibration resistance, and long-term operational stability.

Designed for continuous-duty industrial use, the AZA1193 combines mechanical reliability with operator-friendly controls, making it suitable for both production environments and educational training facilities.

CNC Milling Machine AZA1174

The AZA1174 CNC Milling Machine by AZALAB is a high-performance, industrial-grade machining solution engineered to deliver exceptional precision, speed, and operational reliability. Designed for modern manufacturing environments, this 3-axis CNC milling machine integrates advanced control technology, rigid mechanical construction, and high-speed motion capability to handle complex milling operations with consistent accuracy.

At the core of the AZA1174 is the FANUC Series 31 CNC control system, known globally for its stability, processing speed, and intelligent machining functions. With simultaneous 3-axis control, the machine ensures smooth interpolation, accurate contouring, and efficient cycle times, making it ideal for precision component manufacturing, tool rooms, R&D centers, and production workshops.

The machine is powered by a 200–240 VAC, 50–60 Hz, 3-phase electrical system, delivering reliable performance under continuous industrial duty. Its rigid frame construction and optimized mechanical design minimize vibration and thermal distortion, ensuring dimensional accuracy even during high-speed machining.

Hydraulic Guillotine Shearing Machine AZA1179

The Hydraulic Guillotine Shearing Machine AZA1179 by AZA LAB is a premium, high-precision machine engineered for efficient and accurate cutting of metal sheets. Designed with a hydraulically variable rake angle, this machine delivers superior cutting performance, particularly for thin sheets, while ensuring twist-free and burr-minimized cuts.

Part of AZA LAB’s proven guillotine shear range (Models AZA1179 to AZA1185), the AZA1179 is ideal for fabrication shops, sheet metal industries, maintenance workshops, and light to medium industrial cutting applications where accuracy, safety, and reliability are critical.

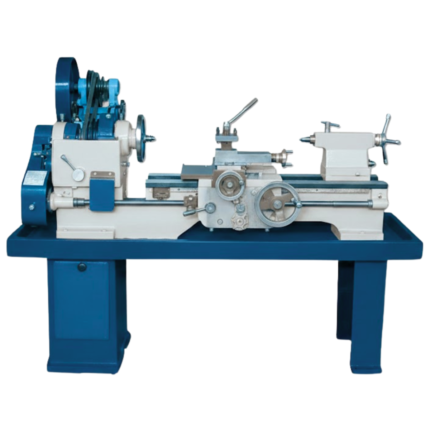

Lathe Machine AZA1175

The AZA LAB Lathe Machine – Model AZA1175 is a robust and reliable machine designed for precision metal cutting and shaping applications in small-scale industries, tool rooms, and workshops. Engineered for accuracy, durability, and ease of operation, this lathe simplifies complex machining tasks while delivering consistent and dependable performance.

Manufactured using solid castings and equipped with precision components, the AZA1175 ensures smooth operation, accurate positioning, and long service life. Its compact yet rigid design makes it an ideal choice for workshops that require efficiency without compromising on machining quality.

Pillar Drilling Machine AZA1194

The AZA LAB Pillar Drilling Machine – Models AZA1194 and AZA1194A is a robust and precision-engineered machine designed for accurate boring and hole-making operations across a wide range of materials. With a maximum drilling capacity of 25 mm, this machine delivers consistent performance, durability, and cost-effective operation.

Built for reliability and ease of use, the AZA1194 series is ideal for workshops, tool rooms, maintenance units, and small to medium-scale industrial applications where accuracy, low vibration, and minimal maintenance are essential.

Slotting Machine AZA1192

The AZA LAB Slotting Machine – Model AZA1192 is a robust, high-performance machine designed for precision slotting, shaping, and cutting operations in metal and wood materials. Engineered for durability and accuracy, this machine is widely used for producing slots on bolt heads, screws, keyways, and other precision components.

Manufactured using high-quality raw materials and advanced engineering techniques, AZA1192 delivers reliable performance in both light and heavy-duty industrial applications. Its hardened and lapped steel gears ensure smooth operation, long service life, and minimal maintenance.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items