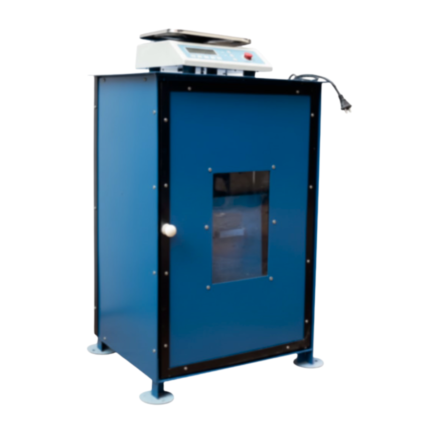

DIGITAL LOS ANGLES ABRASION TESTING MACHINE AZA0987

The AZA0987 Digital Los Angeles Abrasion Testing Machine is an advanced, high-precision laboratory system designed to measure the abrasion resistance and mechanical durability of coarse aggregates used in roads, railways, and concrete structures. Equipped with a digital RPM and programmable timer display, this machine ensures consistent, repeatable, and accurate test performance in compliance with international standards.

Key Functions

- Determines aggregate abrasion resistance under controlled test conditions

- Simulates real-life impact and wear suffered by aggregates

- Provides precise digital RPM and time control for repeatability

- Suitable for routine quality control and research laboratories

Description

Standards Compliance

-

IS 2386 (Part IV)

-

ASTM C131

How It Works

The aggregate sample and hardened steel balls are placed inside a motor-driven rotating steel drum. The drum rotates at a controlled speed of 30–33 RPM for a preset number of revolutions. During rotation, aggregates are subjected to continuous abrasion and impact forces. After completion, the sample is sieved and weighed to calculate the percentage loss (LA Abrasion Value).

Key Features

-

Digital Control Panel with RPM and timer display

-

Heavy-duty steel drum for long operational life

-

Precision motor and gearbox system

-

Low vibration and stable frame design

-

Easy loading and unloading with safety locking cover

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | AZA0987 |

| Drum Diameter | 700 mm |

| Drum Length | 500 mm |

| Rotation Speed | 30 – 33 RPM |

| Motor | 1 HP, Single Phase |

| Control System | Digital RPM & Timer Display |

| Power Supply | 230V AC |

| Standards | IS 2386 (Part IV), ASTM C131 |

Applications

-

Road and highway material testing labs

-

Railway ballast testing

-

Concrete and asphalt aggregate analysis

-

Civil engineering colleges and research centers

FAQ

Q1: What is the purpose of the AZA0987 machine?

It measures the abrasion resistance of coarse aggregates.

Q2: What makes this model different from manual versions?

It includes digital RPM and timer controls for higher accuracy and automation.

Q3: Is it suitable for heavy-duty lab use?

Yes, it is designed for continuous, industrial-grade testing.

Q4: Which standards does it follow?

It complies with IS 2386 (Part IV) and ASTM C131.

Q5: Does it require frequent maintenance?

Only basic periodic cleaning and lubrication are required.

Related products

CYLINDRICAL MEASURES AZA0977

The AZA0977 Cylindrical Measures are precision laboratory containers designed for determining the bulk density (unit weight) and void ratio of fine and coarse aggregates. These measurements are essential for quality control in concrete mix design, highway construction, and geotechnical investigations. Manufactured by Azalab, these measures fully comply with IS 2386 (Part III), ASTM C29, and BS 812 standards.

Key Features

-

Used for measuring bulk density and void ratio of aggregates

-

Available in standard capacities: 3L, 5L, and 15L

-

Heavy-duty mild steel / aluminum construction

-

Smooth, accurately machined internal surfaces

-

Supplied with tamping rod and leveling accessories

-

Corrosion-resistant, long-life surface finish

-

Easy-grip handles for portability

DEVEL ATTRITION TESTER AZA0989

Key Applications

- Road and highway material testing

- Railway ballast quality assessment

- Concrete mix design durability testing

- Civil engineering research & academic laboratories

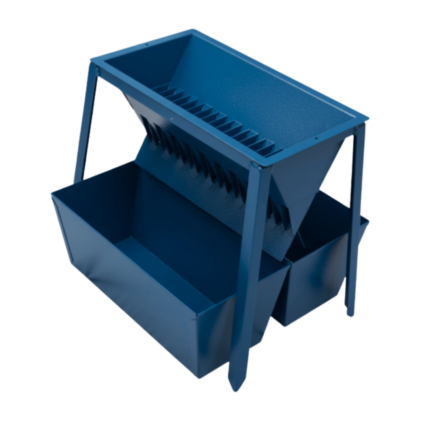

RIFFLE SAMPLE DIVIDER AZA0980

Key Features

- Accurate material splitting for laboratory testing

- Heavy-duty corrosion-resistant metal construction

- Uniform slot widths for consistent sample division

- Smooth-flow chute design for minimal sample loss

- Supplied with two receiving pans for clean, efficient operation

- Compact bench-top design

RIFFLE SAMPLE DIVIDER AZA0980A

Key Features

- Used for precise sample splitting of fine & coarse aggregates

- Uniform chute spacing for even material distribution

- Heavy-duty powder-coated steel body

- Supplied with two high-capacity collection pans

- Smooth-flow chute design to minimize material loss

- Simple, manual operation – no power required

SHAPE INDEX CALIPER AZA0974

The AZA0974 Shape Index Caliper is a precision hand-held measuring instrument designed to evaluate the shape index of coarse aggregates by measuring their flakiness and elongation values. It is an essential tool in construction material testing, helping laboratories and site engineers ensure that aggregates meet dimensional and performance standards as per IS 2386 (Part I).

Key Features

-

Evaluates shape index of coarse aggregates

-

Measures both flakiness and elongation characteristics

-

Durable stainless steel / hardened steel construction

-

Precision engraved measuring scale

-

Ergonomic, easy-to-handle manual design

-

Suitable for laboratory and on-site field use

-

Fully compliant with IS 2386 (Part I)

SPECIFIC GRAVITY AND WATER ABSORPTION OF AGGREGATES AZA0979

Key Features

- Comprehensive apparatus for specific gravity and water absorption testing

- Suitable for both fine and coarse aggregates

- Heavy-duty, corrosion-resistant construction

- High accuracy and repeatable results

- User-friendly configuration for lab and field use

TIG Welding Machine AZA 1235

- TIG welding machine for precise, clean welds

- Dual voltage input (110V/220V) for flexibility

- Advanced IGBT inverter technology

- Digital LCD display for accurate settings

- Ideal for steel, stainless steel, and aluminum

- Overheat and overload protection

- Lightweight and portable for field use

- Model: AZA 1235 – designed for professional use

TILE ABRASION TESTING MACHINE AZA0992

Purpose of Testing

This test determines the depth of wear (in mm) on the tile surface after a fixed number of revolutions under an abrasive load. It helps manufacturers, contractors, and consultants verify whether tiles meet durability requirements for high-traffic applications.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items