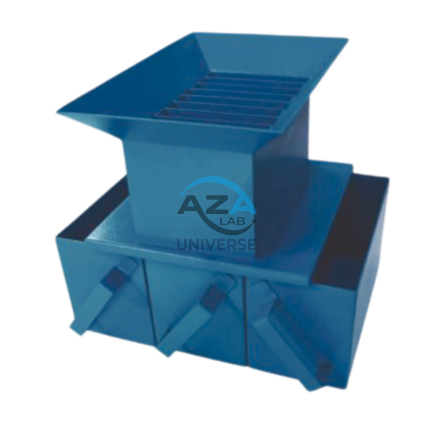

DORRY ABRASION TESTING MACHINE AZA0988

The AZA0988 Dorry Abrasion Testing Machine by Azalab is a robust, motorized laboratory instrument designed to measure the abrasion resistance (wear loss) of coarse aggregates used in road construction, railway ballast, and structural concrete. This machine provides consistent, repeatable test results in accordance with IS 2386 (Part IV) standards, helping engineers and laboratories ensure material durability and performance.

Key Functions

- Evaluates abrasion and wear resistance of aggregates

- Simulates real-life mechanical rubbing and surface wear

- Ensures quality control for construction materials

- Supports research and teaching in civil engineering labs

Description

Standards Compliance

-

IS:2386 (Part IV)

Working Principle

The aggregate sample is placed inside a steel test cylinder mounted on a rotating steel disc. A weighted loading arm applies a constant force on the sample. As the disc rotates at a controlled speed, the sample rubs against emery powder, simulating abrasive wear.

After the specified revolutions, the sample is cleaned, dried, and weighed. The percentage weight loss represents the abrasion value.

Key Features

-

Heavy-duty motorized steel disc system

-

Precisely machined loading arm with dead weights

-

Stable, vibration-resistant steel frame

-

Simple operation with low maintenance

-

Designed for long-term laboratory use

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | AZA0988 |

| Disc Diameter | 20 – 30 cm |

| Motor | 0.5 HP, Single Phase |

| Rotation Speed | 28 – 30 RPM |

| Load Application | 30 – 50 N via weight arm |

| Abrasive Medium | Standard Emery Powder |

| Power Supply | 230V AC |

| Frame Material | Mild steel, powder coated |

| Compliance | IS 2386 (Part IV) |

Applications

-

Road and highway material testing

-

Railway ballast durability testing

-

Concrete mix and aggregate evaluation

-

Civil engineering colleges and R&D labs

FAQ

Q1: What is the AZA0988 used for?

It is used to determine the abrasion resistance of coarse aggregates.

Q2: Which standard does it follow?

It complies with IS 2386 (Part IV).

Q3: Is it suitable for continuous lab use?

Yes, it is designed for heavy-duty laboratory applications.

Q4: What abrasive material is used?

Standard emery powder is used.

Q5: Does the machine require frequent maintenance?

Only basic periodic cleaning and lubrication are required.

Additional information

| Model |

AZA 0989 |

|---|---|

| Disc Diameter |

20 cm – 30 cm |

| Motor |

0.5 HP, Single Phase |

| Load Application |

30–50 N weight through loading lever |

| Abrasive Material |

Standard emery powder |

| Power Supply |

230V AC |

| Construction |

Mild steel frame, corrosion-resistant finish |

| Compliance |

IS 2386 (Part IV) |

Related products

ACCELERATED POLISHING MACHINE AZA0984

Key Features

- Tests polished stone value (PSV) of road aggregates

- Conforms to ASTM D3319 and BS 812 Part 114

- Heavy-duty rotating disc with abrasive feed system

- Integrated water spray system to simulate wet road conditions

- Powder-coated steel body for corrosion resistance

AGGREGATE IMPACT TESTER WITH BLOW COUNTER AZA0983

The AZA0983 Aggregate Impact Tester with Digital Blow Counter is a precision-engineered laboratory apparatus used to determine the Aggregate Impact Value (AIV) of coarse aggregates. It is designed to evaluate the toughness and resistance of aggregates used in road pavements, highways, and structural concrete.

This equipment is manufactured for durability, accuracy, and long service life, and is fully compliant with IS:2386 (Part IV) and BS 812 standards.

Key Features

-

Determines Aggregate Impact Value (AIV) for pavement materials

-

Integrated digital blow counter for accurate strike counting

-

Conforms to IS:2386 (Part IV) and BS 812

-

Heavy-duty, vibration-resistant frame

-

Cylindrical steel cup and standard impact hammer

DENSITY BASKET AZA0978

Key Features

- Used for specific gravity and water absorption tests

- Made from high-quality stainless steel mesh

- Equipped with a strong welded suspension hook

- Corrosion-resistant, rust-free and long-lasting

- Smooth welded edges to prevent sample damage

- Standardized mesh aperture for proper water flow

INDEX APPARATUS (FLOW COEFFICIENT OF FINE AGGREGATES) AZA0975

The AZA0975 Flow Coefficient Index Apparatus is a precision laboratory instrument designed to measure the flow coefficient of fine aggregates, such as natural sand and crushed sand. This test helps evaluate workability, particle shape, and grading, which are critical factors in concrete and mortar mix performance. The apparatus is manufactured in compliance with IS 2386 (Part I) and is widely used in civil engineering laboratories and construction quality control departments.

Key Features

-

Measures flow coefficient of fine aggregates

-

Fully compliant with IS 2386 (Part I)

-

Evaluates workability and particle shape characteristics

-

Supplied as a complete set: funnel, stand, cylinder, and base plate

-

Precision-machined components for consistent results

-

Corrosion-resistant, durable construction

-

Easy manual operation for laboratory and field use

LOS ANGELES ABRASION TESTING MACHINE AZA0986

Key Functions

- Tests abrasion resistance of coarse aggregates

- Evaluates impact strength under repeated load cycles

- Ensures material suitability for roads, highways, and structural concrete

- Provides accurate, repeatable test results for quality control

RIFFLE SAMPLE DIVIDER AZA0980A

Key Features

- Used for precise sample splitting of fine & coarse aggregates

- Uniform chute spacing for even material distribution

- Heavy-duty powder-coated steel body

- Supplied with two high-capacity collection pans

- Smooth-flow chute design to minimize material loss

- Simple, manual operation – no power required

TIG Welding Machine AZA 1235

- TIG welding machine for precise, clean welds

- Dual voltage input (110V/220V) for flexibility

- Advanced IGBT inverter technology

- Digital LCD display for accurate settings

- Ideal for steel, stainless steel, and aluminum

- Overheat and overload protection

- Lightweight and portable for field use

- Model: AZA 1235 – designed for professional use

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items