MIG Welding Machine AZA1238

The AZA LAB MIG Welding Machine – Model AZA1238 is engineered for the most demanding industrial welding applications. Designed to deliver exceptional power, precision, and durability, this machine offers a high welding current range of 100–600 A, making it ideal for large-scale fabrication, heavy structural welding, and industrial manufacturing environments.

Built with a rugged construction and equipped with 100% copper winding, the AZA1238 ensures high electrical efficiency, stable arc characteristics, and long-term reliable performance even under continuous operation.

Description

The AZA 1238 MIG Welding Machine is engineered for the most challenging welding applications. With a high current range of 100-600A, this machine is built to handle large-scale industrial tasks. It features step-type voltage control for precision, a burn-back facility for clean welds, and a robust design that ensures durability in demanding environments. With 100% copper winding, it offers excellent efficiency and reliabl

Key Benefits

- High current output for heavy-duty and large-scale welding jobs

- Stable and consistent welding arc for superior weld quality

- Robust construction suitable for harsh industrial environments

- Low maintenance and reduced downtime

- High efficiency and durability with 100% copper winding

Features

- High Welding Current Range (100–600 A)

Suitable for thick materials and demanding industrial welding applications.

- Step-Type Voltage Control

Enables precise adjustment of welding parameters for different materials and thicknesses.

- Rugged & Durable Design

Built to withstand continuous use in heavy fabrication shops and industrial sites.

- Burn-Back Facility

Ensures cleaner weld starts and finishes by preventing wire sticking.

- 100% Copper Winding

Provides excellent conductivity, improved heat dissipation, and extended service life.

- Low Maintenance Operation

Designed to minimize breakdowns and ensure uninterrupted productivity.

Applications

- Heavy structural fabrication

- Industrial manufacturing units

- Large-scale construction projects

- Shipbuilding and heavy engineering

- Maintenance and repair in industrial plants

Technical Specifications – AZA1238

| Specification | Details |

|---|---|

| Model | AZA1238 |

| Make | AZA LAB |

| Supply Voltage | 380 – 440 V |

| Phase | 3 Phase |

| Open Circuit Voltage | 18 – 58 V |

| Welding Current Range | 100 – 600 A |

| Welding Current @ 60% Duty Cycle | 600 A |

| Insulation Class | Class H |

| Permissible Wire Diameter | 0.8 – 1.6 mm |

Performance & Reliability

The AZA1238 MIG Welding Machine is designed to deliver powerful, consistent, and reliable welding performance in high-load industrial environments. Its advanced electrical design, combined with rugged mechanical construction, ensures long operational life and superior welding results.

Why Choose AZA LAB?

AZA LAB is a trusted manufacturer of industrial welding equipment known for quality, durability, and performance. The MIG Welding Machine AZA1238 represents AZA LAB’s commitment to providing high-efficiency solutions for professional welders and industrial users.

e performance, making it the ultimate choice for professional welders.

Related products

Hydraulic Press Machine AZA1196

The AZA LAB Hydraulic Press Machine – Model AZA1196 is a robust and reliable solution engineered for demanding industrial pressing operations. Designed with a highly rigid structure and powered by an advanced hydraulic power pack, this machine delivers consistent force, precision control, and long-term durability.

Built to handle a wide range of industrial requirements, the AZA1196 is available in capacities ranging from 5 tonnes to 200 tonnes, making it suitable for light-duty assembly tasks as well as heavy-duty forming, pressing, and straightening applications across multiple industries.

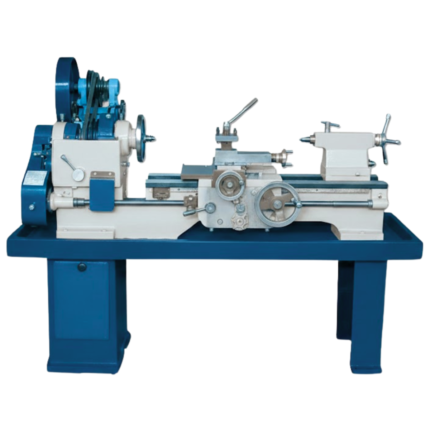

Lathe Machine AZA1175

The AZA LAB Lathe Machine – Model AZA1175 is a robust and reliable machine designed for precision metal cutting and shaping applications in small-scale industries, tool rooms, and workshops. Engineered for accuracy, durability, and ease of operation, this lathe simplifies complex machining tasks while delivering consistent and dependable performance.

Manufactured using solid castings and equipped with precision components, the AZA1175 ensures smooth operation, accurate positioning, and long service life. Its compact yet rigid design makes it an ideal choice for workshops that require efficiency without compromising on machining quality.

Pillar Drilling Machine AZA1194

The AZA LAB Pillar Drilling Machine – Models AZA1194 and AZA1194A is a robust and precision-engineered machine designed for accurate boring and hole-making operations across a wide range of materials. With a maximum drilling capacity of 25 mm, this machine delivers consistent performance, durability, and cost-effective operation.

Built for reliability and ease of use, the AZA1194 series is ideal for workshops, tool rooms, maintenance units, and small to medium-scale industrial applications where accuracy, low vibration, and minimal maintenance are essential.

Pipe Threading machine AZA1199

The AZA LAB Pipe Threading Machines – Models AZA1199, AZA1199A, and AZA1199B are heavy-duty industrial machines designed for accurate and efficient pipe and rod threading using an advanced chip-less cold forming (thread rolling) process. This method forms thread roots and crests by material displacement rather than cutting, ensuring zero material waste, superior thread strength, and excellent surface finish.

Engineered with a robust fabricated steel frame, versatile operation modes, and advanced cooling and lubrication systems, these machines are ideal for high-performance threading applications across multiple industries.

Plate Rolling Machine AZA1195

The AZA LAB Plate Rolling Machine – Model AZA1195 is a high-performance hydraulic machine engineered for accurate and consistent metal plate rolling. Designed with a 3-roll pyramid configuration and double pre-bending arrangement, this machine delivers superior bending accuracy and repeatable results for industrial fabrication applications.

Built using high-strength alloy steel rolls, robust hydraulics, and internationally approved electrical components, AZA1195 ensures durability, operational safety, and long service life even under demanding working conditions

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items