AIR ENTRAINMENT METER AZA1146

Purpose of Air Entrainment Testing

Entrained air is critical for:- Freeze–thaw durability

- Crack resistance

- Improved workability

- Reduced bleeding and segregation

B TYPE AIR ENTRAINMENT METER AZA1145

Applications

Widely used across the concrete testing sector, the AZA1145 is ideal for:- Civil construction quality-control laboratories

- Cement and concrete R&D departments

- Ready-mix concrete testing facilities

- Engineering colleges and training institutes

- Material testing and QA/QC divisions

Why Air Entrainment Testing Is Important

Entrained air improves:- Workability of fresh concrete

- Durability in freeze–thaw conditions

- Resistance to scaling, cracking, and surface deterioration

- Confirm mix design compliance

- Validate field concrete quality

- Optimize concrete mixes for extreme environments

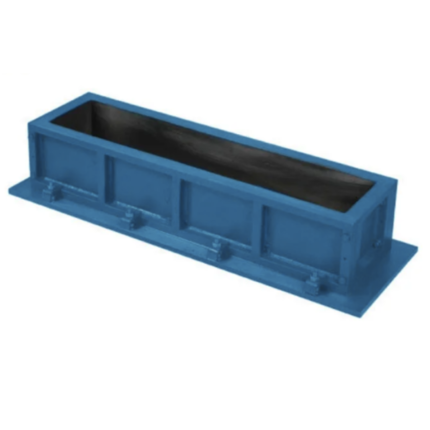

BEAM MOULD AZA1124

Purpose & Importance

Flexural strength testing evaluates a concrete beam’s ability to resist bending stress. Standards such as IS 516, ASTM C78, and BS EN 12390-5 specify strict guidelines for specimen dimensions and surface finish. The AZA1124 Beam Mould enables users to produce uniform, high-quality concrete beams with precise cross-sections, ensuring reliability and compliance during flexural strength evaluation.Beams cast from AZA1124 are used for:

- Flexural tensile strength testing

- Load-bearing capacity studies

- Structural behavior simulations

- R&D on mix designs and reinforcement additives

Ideal for:

- Civil engineering research laboratories

- Cement product quality assurance departments

- Construction material testing centers

- Technical universities and engineering institutions

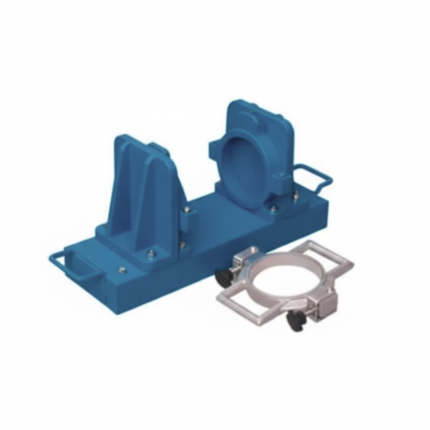

CAPPING SET (HORIZONTAL) AZA1163

Enhanced Ergonomics & Operational Control

This horizontal version is particularly suited for busy laboratories that prioritize operator comfort, safe handling of molten capping compounds, and efficient sample processing. With the cube placed on its side, technicians gain better access to the exposed surface, simplifying the controlled pouring of sulfur or gypsum-based capping materials. The horizontal layout also minimizes spill risks and enhances workflow during continuous testing operations.Robust Construction & Precision Alignment

Manufactured from powder-coated heavy-duty steel, the frame is designed for long-term laboratory use. The precision-machined steel base ensures proper seating and alignment of the cube, eliminating tilt or misalignment that could compromise test accuracy. The single-slot holder keeps the specimen firmly in place during the capping process.Once the first face is capped and cured, the cube is rotated to prepare the opposite surface. After both ends are perfectly level and parallel, the specimen is ready for compressive strength testing in a Universal Testing Machine (UTM).CAPPING SET (VERTICAL) AZA1164

The AZA-LAB Vertical Capping Set is a precision tool designed to prepare 150 mm concrete cube specimens with smooth, level, and parallel end surfaces prior to compressive strength testing. By holding the specimen upright and ensuring perfect alignment, this apparatus enables consistent and accurate results in accordance with ASTM C617 and IS 516.

Purpose & Function

During compressive strength testing, concrete cubes must have properly prepared surfaces to guarantee uniform load transfer between the testing platens. Any irregularity can cause stress concentrations or premature failure. The Vertical Capping Set provides a stable, guided fixture that maintains the cube in a perfect vertical orientation while capping compound is applied to each end.

Once sulfur or gypsum-based capping material is poured and allowed to harden, the ends become flat, parallel, and ready for precise compression testing in a Universal Testing Machine (UTM).

CHASE AIR INDICATOR AZA1105

AZA1105 Chase Air Indicator is a compact, lightweight, and highly practical field instrument designed to measure the air content in freshly mixed concrete. It is widely used in construction sites where rapid quality decisions are required and laboratory testing equipment is not readily available.

This device serves as a reliable field alternative to standard air content methods such as ASTM C231 (Pressure Method) and ASTM C173 (Volumetric Method). While it is not intended to replace laboratory-grade instruments, it provides fast, useful guidance that helps engineers and site supervisors maintain proper concrete mix quality.

Air entrainment plays a critical role in concrete durability, especially in regions exposed to freeze–thaw cycles, and contributes significantly to workability and pumpability of concrete. AZA1105 helps ensure that air content remains within the recommended range (typically 4%–7%), reducing the risk of weak or brittle concrete.

The working principle is based on fluid displacement and vacuum pressure balance. A representative mortar sample is collected and placed inside the testing chamber, where a controlled vacuum is applied. The internal pressure difference is translated directly to a calibrated dial gauge showing the approximate air content percentage.

With no electrical components, moving mechanical assemblies, or complex maintenance requirements, the AZA1105 is extremely reliable and built for tough field conditions. Its rugged body and easy-to-read dial make it suitable for continuous daily use in real-world jobsite environments.

COMPACTION FACTOR APPARATUS AZA1107

- Precision measurement of compaction factor for dry and stiff concrete

- Double-hopper system with smooth trap release

- Conforms to IS 1199 and BS 1881 standards

- Suitable for precast plants, RMC units, and civil engineering labs

- Rugged, powder-coated mild-steel construction

- Cylindrical container included for final measurement

COMPRESSION AND FLEXURAL TESTING MACHINES SPLITTING TENSILE TEST DEVICE AZA1141

The AZA1141 Integrated Concrete Strength Testing System is a multifunctional, heavy-duty testing solution combining compression testing, flexural testing, and splitting tensile testing in a single, robust machine. Engineered for high accuracy, reliability, and compliance with global standards, it is ideal for laboratories, research facilities, QC departments, and construction material testing centers requiring a complete mechanical testing suite within one compact frame.

This advanced system is designed to evaluate:

• Compressive strength of concrete cubes and cylinders (ASTM C39)

• Flexural strength of concrete beams (ASTM C78)

• Indirect tensile strength using the splitting tensile test (ASTM C496)

A unified hydraulic or servo-controlled loading frame ensures precise, stable load application across all test modes. Interchangeable jigs, platens, and beam fixtures enable rapid switching between test types, significantly improving laboratory productivity. Each frame is constructed using high-strength, corrosion-resistant steel with precision machining to maintain alignment and load accuracy even under extreme capacities (1000–3000 kN).

Advanced variants include digital control consoles with PC connectivity, real-time graphing, and automated data acquisition, while manual models cater to field or budget-oriented labs.

COMPRESSION TESTING MACHINE (CHANNEL TYPE LOAD FRAME) HAND OPERATED AZA1133

Key Features

- Heavy C-channel welded frame for exceptional stability and structural durability

- Fully compliant with IS 516 and BS 1881 standards

- Available capacities from 50 kN to 2000 kN

- Hardened, ground, mirror-polished platens with centering grooves

- Manual operation using hydraulic jack and precision lead screw

- Self-aligning spherical seat on upper platen

- Rectangular platens standard; square/circular optional

- Suitable for cubes, cylinders, bricks, blocks, and tiles

COMPRESSION TESTING MACHINE (Four Pillar) Hand Cum Electrical Operated AZA1134

- Four-pillar heavy-duty steel load frame for maximum rigidity

- Dual-mode operation: hand pump + electric motor

- Fully compliant with IS 516 and BS 1881

- Fast/slow rate loading regulator for controlled test pace

- 20 cm analog dial gauge with maximum load pointer

- Optional Digital Load Indicator and up to 3 load gauges

- Supports cubes and cylinders; spacers included

CONCRETE CURING RACKS AZA1157

The AZA-LAB Concrete Curing Rack (Model AZA1157) is a heavy-duty storage solution designed for organized, efficient, and standardized curing of concrete cube specimens. Constructed from high-strength galvanized or powder-coated steel, this rack ensures long service life, superior load-bearing capability, and full resistance to corrosion even in wet and humid curing environments.

Engineered for professional material testing laboratories, construction quality control units, and precast manufacturing facilities, the AZA1157 rack provides optimized storage for 100 mm and 150 mm cube moulds. With a multi-level, space-saving design, the rack supports consistent curing practices in accordance with IS 516 and ASTM C31 standards.

Each shelf is built to withstand the weight of freshly cast concrete without deformation, while the open-frame design promotes uniform airflow and minimizes external contamination. Optional wheels, trays, and locking systems enhance mobility and usability, making the AZA1157 a versatile solution for both stationary and mobile lab setups.

CONCRETE FLOW TABLE TEST SET AZA1110

AZA1110 Concrete Flow Table Test Set is a precision-engineered laboratory apparatus designed to determine the workability, consistency, and flow characteristics of fresh concrete. It is especially suitable for Self-Compacting Concrete (SCC), precast concrete, and high-consistency mixes where the traditional slump test is not effective.

This test set works by allowing a freshly mixed concrete sample to spread under controlled, repeated vertical jolts of a mechanically calibrated table. The final spread diameter of the concrete is measured to assess its flowability and uniformity.

Built with a rigid, precisely machined table surface, the AZA1110 ensures repeatable and reliable results. Its heavy-duty construction allows long-term use in demanding laboratory environments while remaining easy to clean, store, and maintain.

The apparatus complies with major international standards including IS 1199, ASTM C1437, and BS EN 12350-5, making it suitable for both domestic and international testing requirements.

The word concrete comes from the Latin word “concretus” that means compact or condensed; in fact it is well known that since the second century the Romans mixed quicklime with pozzolan to enhance its hydraulic properties and then mixed it with aggregates in order to obtain a robust stone-like material for the construction of roads and structures. Since then the quality and the production technology of concrete strongly evolved hence considerable care supported by knowledge is required to produce quality concrete. Accurate Business, since several years manufacturer leader of testing equipment, proposes a complete range of testing equipment to satisfy practically all the EN and other National Standards.

NDT

The need to assess the quality and integrity of new buildings and the preservation of historical buildings and monuments, has produced and encouraged modern techniques along with related equipment for non destructive testing, known as NDT. Controls proposes a vast selection of NDT instruments and apparatus with precise indications concerning the product use and the relative applications

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items