Abrasion Testing Machine for Glazed Tiles AZA1261

The AZA LAB Abrasion Testing Machine for Glazed Tiles (AZA1261) is a precision-engineered laboratory instrument designed for the accurate determination of abrasion resistance in glazed ceramic tiles. Fully compliant with BIS 13630-11 and EN ISO 10545-7, this machine is essential for evaluating tile durability and surface wear performance in accordance with international quality standards.

The AZA1261 simulates real-world foot traffic and surface wear conditions, enabling manufacturers, testing laboratories, and quality control departments to verify that glazed tiles maintain their appearance, texture, and integrity even under high-traffic usage.

Abrasion Testing Machine for Glazed Tiles AZA1262

The AZA LAB Abrasion Testing Machine for Glazed Tiles (AZA1262) is a robust, high-performance laboratory instrument engineered for precise and high-speed abrasion resistance testing of glazed ceramic tiles. Fully compliant with BIS 13630-11 and EN ISO 10545-7, this machine is designed to ensure reliable evaluation of tile durability under simulated real-world wear conditions.

With the capability to test up to four specimens simultaneously, the AZA1262 significantly improves testing efficiency while maintaining exceptional accuracy and repeatability—making it ideal for tile manufacturers, certification laboratories, and quality control departments

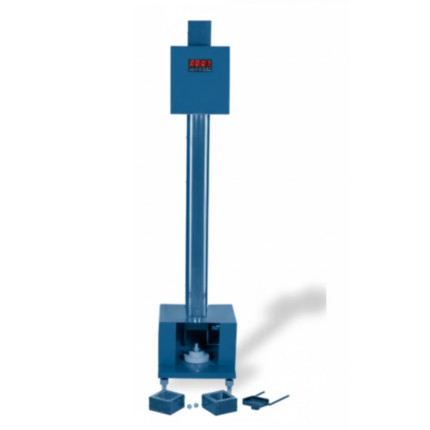

Ball Release for Impact Resistance Tester AZA1295

The AZA LAB Ball Release for Impact Resistance Tester (AZA1295) is a precision-engineered laboratory accessory designed to deliver accurate, repeatable, and standardized ball drop impact testing for a wide range of materials. It is an essential component of drop weight impact testing systems used in research & development, quality control, compliance testing, and academic laboratories.

This device ensures controlled release of a weighted ball from a defined height, eliminating operator variability and guaranteeing consistent impact energy in every test. The AZA1295 is widely used to evaluate impact strength, puncture resistance, and breakage behavior of materials under sudden mechanical stress.

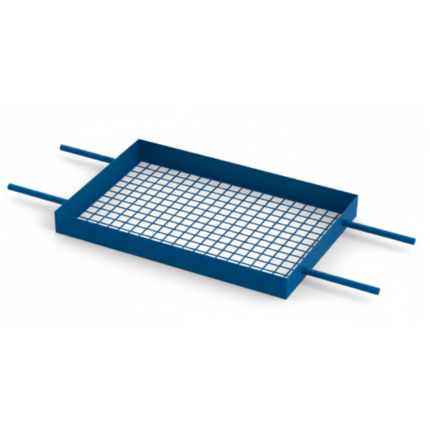

BALLAST SIEVE – 100 x 70 x 10 cm – 65 mm AZA1299

The AZA1299 Ballast Sieve (65 mm) is a rugged, industrial-grade sieve specifically engineered for the separation and grading of coarse aggregates, railway ballast, and large stone particles used in construction and civil engineering applications. With its large working area and reinforced frame, the sieve is ideally suited for high-volume, heavy-material screening in laboratories as well as demanding field environments.

Designed to meet international aggregate testing requirements, the AZA1299 delivers reliable, repeatable results essential for material quality assurance, gradation control, and compliance verification.

DEEP ABRASION MACHINE FOR UNGLAZED TILES AZA1260

The AZA LAB Deep Abrasion Testing Machine – Model AZA1260 is a high-performance laboratory instrument specifically designed to measure the deep abrasion resistance of unglazed ceramic tiles in strict accordance with ISO 10545-6 and IS 13630 (Part 12) standards. This machine is an essential quality assurance tool for tile manufacturers, certification bodies, and research laboratories focused on durability and wear performance.

Deep abrasion resistance is a critical parameter for unglazed tiles used in high-traffic commercial, industrial, and public spaces, where surface wear directly impacts service life and safety. The AZA1260 delivers accurate, repeatable, and standardized results that reflect real-world abrasion conditions.

DESICCATORS AZA1266

A desiccator is an essential laboratory container used for dry storage and protection of hygroscopic materials from atmospheric moisture. Our desiccators are designed to offer airtight sealing, durability, and resistance to chemical reactions.

Whether you're storing anhydrous chemicals, moisture-sensitive reagents, or conducting vacuum drying, our desiccators are built for consistent, high-performance usage.

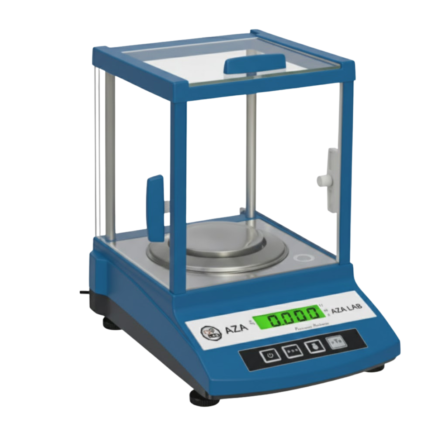

ELECTRONIC WEIGHING BALANCE AZA1267

The AZA LAB Electronic Weighing Balance – Model AZA1267 is a high-precision laboratory instrument engineered for accurate and reliable mass measurement across a wide range of analytical and quality control applications. With a readability of 0.001 g (1 mg) and external calibration, this balance delivers consistent results where precision is critical.

Designed for durability and ease of use, the AZA1267 features a stainless-steel weighing pan, anti-shock protection, and a clear LED digital display, all housed in a compact and robust body. Its dual power supply (AC adapter with in-built rechargeable battery) ensures uninterrupted operation in both laboratory and field environments

FLUX OVEN – 50 KG – STAINLESS STEEL AZA1273

The AZA LAB Flux Oven (Model AZA1273) is a high-performance drying and heating oven engineered for precise, uniform thermal processing of flux materials in laboratory and industrial environments. Designed with a robust double-walled construction and high-efficiency insulation, the oven delivers excellent thermal stability, energy efficiency, and long-term durability.

With a temperature range of 50°C to 400°C, forced air circulation, and a digital PID temperature controller with auto-tune, the AZA1273 ensures accurate temperature control and even heat distribution throughout the chamber. It is ideally suited for demanding applications in ceramics, metallurgy, materials testing, and quality control laboratories.

Enhanced safety is ensured through over-temperature protection with an audible alarm, while the system is validation-ready and compatible with optional data logging and thermal mapping accessories.

Gloss Meter – Single Angle Models AZA1298

The AZA1298 Single Angle Gloss Meter is a compact, high-precision surface gloss measurement instrument designed for accurate, repeatable, and standardized gloss evaluation in laboratory, production, and field environments. Utilizing a fixed-angle optical geometry, this gloss tester delivers consistent gloss readings in Gloss Units (GU), making it ideal for routine quality control and surface finish verification.

Engineered for ease of use and compliance with international standards, the AZA1298 is widely used across paint, coatings, plastics, wood, packaging, automotive, and furniture industries where surface appearance is critical.

Gloss Meter – Triple Angle Models AZA1298A

The AZA1298A Triple Angle Gloss Meter is a high-precision surface gloss measurement instrument designed for professional quality control, inspection, and compliance testing. It measures surface gloss accurately at 20°, 60°, and 85°, covering high-gloss, semi-gloss, and matte finishes in a single compact device.

Engineered for industrial, laboratory, and field applications, AZA1298A ensures consistent, repeatable, and standards-compliant gloss evaluation across a wide range of materials.

High-precision Thermal Expansion Measurement for Ceramics & Solids AZA1269

The AZA1269 High-Performance Dilatometer is an advanced thermal analysis instrument engineered for precise measurement of linear thermal expansion and contraction of solid materials at temperatures up to 1400 °C. Designed for demanding laboratory and industrial environments, the system delivers high accuracy, repeatability, and long-term thermal stability, making it ideal for material characterization, research, and quality assurance.

This instrument is widely used in ceramics, refractories, advanced composites, polymers, and sintered materials, where understanding dimensional change under heat is critical to product performance and safety.

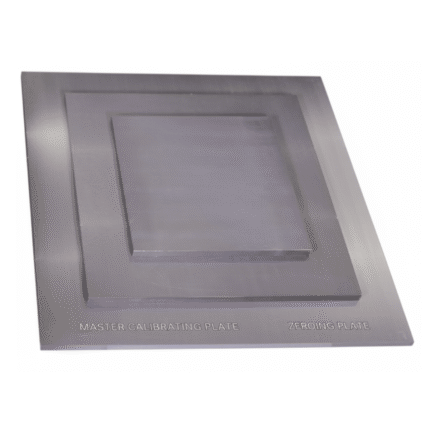

MASTER CALIBRATING PLATE / ZEROING PLATE AZA1270

AZA LAB's Master Calibrating Plate—also known as a Zeroing Plate—is a precision-engineered aluminum reference plate designed for accurate calibration of Universal Gauges and Plucometers. Manufactured in compliance with IS 13630 (Part-1) and EN ISO 10545 (Part-2) standards, it ensures reliable and repeatable zero-point reference during dimensional testing of ceramic tiles and similar materials.

The plate is available in a wide range of sizes to suit various laboratory and industrial applications. With a flatness accuracy of ±0.1 mm and a sturdy 12 mm thickness, it provides a stable and durable base for equipment calibration.

Whether in QC labs or production floors, the AZA LAB Zeroing Plate is an essential tool for maintaining measurement consistency and ensuring compliance with international tile testing standards.

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items