SIEVE SHAKER AZA1302

The AZA1302 Sieve Shaker is a robust, precision-engineered instrument designed to deliver accurate, repeatable, and standardized particle size analysis for a wide range of granular materials. By combining rotational vibration with mechanical tapping, the AZA1302 closely simulates traditional hand sieving while eliminating operator variability, fatigue, and inconsistency.

This makes the AZA1302 an essential laboratory instrument for soil mechanics, aggregates testing, powders, granules, cement, pharmaceuticals, food products, mining materials, and construction quality control.

Manual sieving is often time-consuming and subject to human error. The AZA1302 automates the process, significantly improving test efficiency, reproducibility, and compliance with international standards such as ASTM E11 and ISO 3310.

Description

Working Principle

The AZA1302 operates using a dual-action motion system:

-

Horizontal circular motion distributes the sample evenly across the sieve surface

-

Vertical mechanical tapping assists particles in passing through mesh openings and prevents clogging

This combined motion ensures efficient separation of particles across a stacked series of sieves, producing clear and reliable gradation results in a single test cycle.

A built-in digital timer allows precise control of test duration, ensuring consistent conditions for repeat testing and inter-laboratory comparison.

Key Features

-

Measures particle size distribution accurately and repeatably

-

Dual-action motion: circular vibration + mechanical tapping

-

Compatible with standard 8-inch (20 cm) and 12-inch (30 cm) test sieves

-

Built-in digital timer for precise test control

-

Uniform tapping force for reproducible results

-

Reduces manual sieving time and operator dependency

-

Rugged steel construction for long-term laboratory use

-

Suitable for continuous operation in demanding environments

Applications

-

Soil Mechanics & Geotechnical Testing

Classification of sand, silt, and gravel samples -

Construction Materials

Aggregate gradation for concrete, asphalt, and road materials -

Cement & Building Materials

Fineness and particle distribution analysis -

Mining & Metallurgy

Ore sizing and material screening -

Pharmaceuticals

Powder and granule size verification -

Food & Agriculture

Grain, flour, and powdered material consistency testing -

Environmental & Academic Laboratories

Research and teaching applications

Compliance with Standards

The AZA1302 Sieve Shaker is designed to meet or exceed the requirements of:

-

ASTM E11 – Standard Specification for Woven Wire Test Sieve Cloth

-

ISO 3310 – Test sieves – Technical requirements and testing

These standards ensure accuracy, repeatability, and global acceptance of test results.

Technical Specifications

| Feature | Specification |

|---|---|

| Model | AZA1302 |

| Device Type | Electromechanical Rotap Sieve Shaker |

| Compatible Sieves | 8” (20 cm) and 12” (30 cm) diameter |

| Sieve Capacity | Up to 6–8 full-height sieves (or equivalent half-height) |

| Motion Type | Horizontal circular vibration with mechanical tapping |

| Timer | Digital, programmable |

| Operation Mode | Dry sieving |

| Frame Material | Heavy-duty steel with anti-corrosion coating |

| Power Supply | 220V / 110V AC, 50/60 Hz |

| Noise Level | ≤ 85 dB (sound enclosure optional) |

| Weight | Approx. 40–60 kg (model dependent) |

| Compliance | ASTM E11, ISO 3310 |

What’s Included

-

1 × AZA1302 Sieve Shaker

-

1 × Digital timer control unit (integrated)

-

1 × Sieve clamping assembly

-

1 × Sample receiver pan

-

1 × Power cable

-

1 × User operation & maintenance manual

-

1 × Calibration / compliance certificate

Optional Accessories:

-

Sound-dampening enclosure

-

Additional sieve clamps

-

Customized sieve holders

Key Advantages

-

High Accuracy & Repeatability – Consistent results across multiple tests

-

Time Efficient – Significantly reduces testing duration compared to manual sieving

-

Non-Destructive Testing – No alteration of sample properties

-

User-Friendly Operation – Simple setup with minimal training required

-

Durable Construction – Designed for continuous lab usage

-

Standards Compliant – Suitable for audits, tenders, and certified testing labs

Frequently Asked Questions (FAQ)

Q1: What is the primary use of the AZA1302 Rotap Sieve Shaker?

It is used for standardized particle size analysis of granular and powdered materials.

Q2: Can the AZA1302 perform wet sieving?

No. This model is designed for dry sieving only. Wet sieving requires specialized equipment.

Q3: How many sieves can be stacked at once?

Typically 6–8 full-height sieves, depending on sample volume and sieve type.

Q4: Is the instrument noisy during operation?

Mechanical tapping generates sound; however, optional sound enclosures are available for noise reduction.

Q5: Is the equipment suitable for routine lab use?

Yes. The AZA1302 is built for continuous, long-term operation in quality control and research laboratories.

Why Choose AZA1302 from AZA LAB / Azalab?

-

Proven design aligned with international standards

-

Reliable, repeatable, and accurate particle size analysis

-

Heavy-duty construction for demanding lab environments

-

Reduced operator variability and improved productivity

-

Backed by expert technical support and calibration services

Additional information

| Device Type |

Electromechanical Sieve Shaker |

|---|---|

| Compatible Sieves |

8" or 12" diameter (stackable) |

| Shaking Motion |

Horizontal circular with mechanical tapping |

| Material Capacity |

Variable, based on sieve stack |

-

Dual-Action Motion:

Simultaneously performs a circular rotation and mechanical tapping to effectively separate particles and prevent clogging of sieves—mimics manual sieving with greater repeatability. -

Capacity:

Accommodates 7–8 standard test sieves (depending on sieve height), plus lid and receiver. -

Versatile Compatibility:

Available for both 20 cm and 30 cm diameter test sieves. -

Low Noise Operation:

Designed with noise-dampening features to maintain a quiet lab environment. -

Durable Construction:

Built with high-quality steel housing and a heavy-duty motor for long-lasting performance in daily lab use. -

Adjustable Timing & Controls:

Timer and speed controls for customized test cycles. -

User-Friendly Interface:

Plug-and-play setup with low maintenance requirements.

Applications:

-

Soil mechanics and geotechnical testing

-

Aggregate size classification in concrete & asphalt labs

-

Cement fineness testing

-

Powder material screening

-

Pharmaceutical granule separation

-

Food & beverage industry quality control

Why Choose the AZA LAB ROTAP Sieve Shaker?

-

Proven design based on global testing standards

-

Consistent and repeatable results

-

Durable build for long-term lab use

-

Quiet, efficient operation

-

Expert technical support and warranty service

-

Available in both 20 cm and 30 cm variants

You may also like…

Abrasion Testing Machine for Glazed Tiles AZA1261

The AZA LAB Abrasion Testing Machine for Glazed Tiles (AZA1261) is a precision-engineered laboratory instrument designed for the accurate determination of abrasion resistance in glazed ceramic tiles. Fully compliant with BIS 13630-11 and EN ISO 10545-7, this machine is essential for evaluating tile durability and surface wear performance in accordance with international quality standards.

The AZA1261 simulates real-world foot traffic and surface wear conditions, enabling manufacturers, testing laboratories, and quality control departments to verify that glazed tiles maintain their appearance, texture, and integrity even under high-traffic usage.

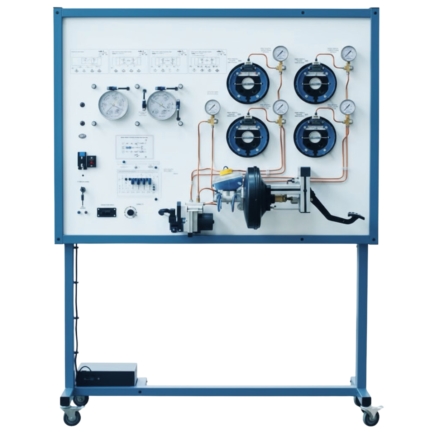

ABS Braking System Training Board Simulator AZA1245

The AZA1245 AZALAB ABS Braking System Training Board Simulator is a fully functional automotive training platform designed to provide in-depth, hands-on understanding of Anti-lock Braking System (ABS) operation, diagnostics, and repair procedures. Built using real automobile components, this simulator enables students and technicians to study ABS structure, electronic control, hydraulic behavior, and fault diagnostics in a safe and controlled learning environment.

This training system is ideal for automotive training institutes, engineering colleges, technical schools, and service technician programs, supporting both instructional demonstrations and practical troubleshooting exercises.

Air Bag Trainer AZA1246

The AZA1246 AZALAB Air Bag Trainer is a comprehensive educational training platform designed to demonstrate the structure, operation, diagnostics, and fault analysis of modern automotive airbag systems, also known as Supplemental Restraint Systems (SRS). Built using OEM automotive components, this trainer delivers a realistic learning experience while maintaining complete operational safety.

This system is ideally suited for automotive engineering colleges, ITIs, polytechnic institutes, vocational training centers, and service technician programs, enabling both theoretical instruction and hands-on diagnostics practice.

Closed Cup Flash Point Tester AZA1280

The AZA1280 Closed Cup Flash Point Tester from AZA Lab is a high-performance, fully automated instrument designed for accurate determination of flash points of volatile and combustible liquids using the Tag Closed Cup (TCC) method, in full compliance with ASTM D56 standards.

This analyzer is specifically intended for liquids with flash points below 93°C (200°F) and low viscosity samples, making it an essential tool for petroleum laboratories, fuel testing facilities, quality control departments, and R&D centers requiring high precision at low and sub-zero temperatures.

METALLURGICAL INVERTED MICROSCOPE AZA1016

Key Advantages

- Inverted optical system for easy sample placement

- Ideal for large, heavy, or irregular samples

- Stable viewing plane for uniform focusing

- Reflected (Epi) illumination for opaque materials

- Safe operation with reduced risk of objective damage

Petroleum Product Distillation Tester AZA1284

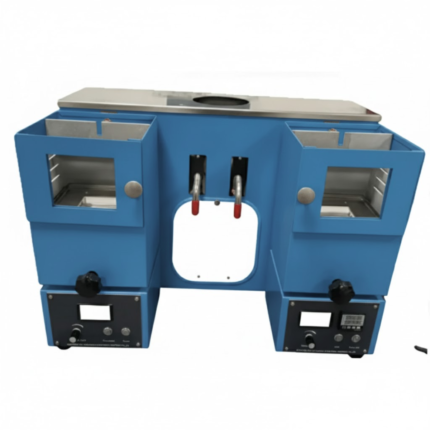

The AZA1284 Manual Distillation Unit from AZA Lab is a high-precision, front-type petroleum distillation system engineered for accurate determination of distillation characteristics of petroleum products in accordance with ASTM D86 and GB/T 6536 test methods. Designed for laboratories that require reliable manual control with superior thermal stability, this unit delivers consistent, repeatable, and standards-compliant results.

With its dual-unit configuration, independently controlled constant-temperature baths, and continuously adjustable heating power, the AZA1284 offers exceptional flexibility and efficiency for routine quality control, inspection, and research applications.

Related products

Abrasion Testing Machine for Glazed Tiles AZA1262

The AZA LAB Abrasion Testing Machine for Glazed Tiles (AZA1262) is a robust, high-performance laboratory instrument engineered for precise and high-speed abrasion resistance testing of glazed ceramic tiles. Fully compliant with BIS 13630-11 and EN ISO 10545-7, this machine is designed to ensure reliable evaluation of tile durability under simulated real-world wear conditions.

With the capability to test up to four specimens simultaneously, the AZA1262 significantly improves testing efficiency while maintaining exceptional accuracy and repeatability—making it ideal for tile manufacturers, certification laboratories, and quality control departments

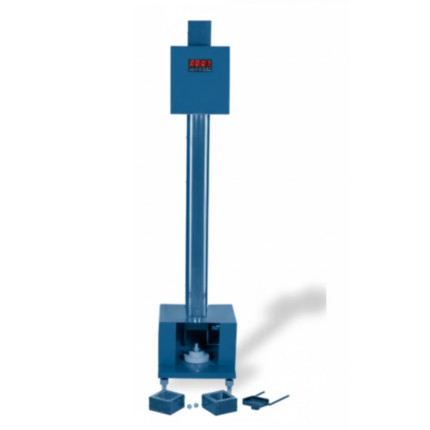

Ball Release for Impact Resistance Tester AZA1295

The AZA LAB Ball Release for Impact Resistance Tester (AZA1295) is a precision-engineered laboratory accessory designed to deliver accurate, repeatable, and standardized ball drop impact testing for a wide range of materials. It is an essential component of drop weight impact testing systems used in research & development, quality control, compliance testing, and academic laboratories.

This device ensures controlled release of a weighted ball from a defined height, eliminating operator variability and guaranteeing consistent impact energy in every test. The AZA1295 is widely used to evaluate impact strength, puncture resistance, and breakage behavior of materials under sudden mechanical stress.

DEEP ABRASION MACHINE FOR UNGLAZED TILES AZA1260

The AZA LAB Deep Abrasion Testing Machine – Model AZA1260 is a high-performance laboratory instrument specifically designed to measure the deep abrasion resistance of unglazed ceramic tiles in strict accordance with ISO 10545-6 and IS 13630 (Part 12) standards. This machine is an essential quality assurance tool for tile manufacturers, certification bodies, and research laboratories focused on durability and wear performance.

Deep abrasion resistance is a critical parameter for unglazed tiles used in high-traffic commercial, industrial, and public spaces, where surface wear directly impacts service life and safety. The AZA1260 delivers accurate, repeatable, and standardized results that reflect real-world abrasion conditions.

DESICCATORS AZA1266

A desiccator is an essential laboratory container used for dry storage and protection of hygroscopic materials from atmospheric moisture. Our desiccators are designed to offer airtight sealing, durability, and resistance to chemical reactions.

Whether you're storing anhydrous chemicals, moisture-sensitive reagents, or conducting vacuum drying, our desiccators are built for consistent, high-performance usage.

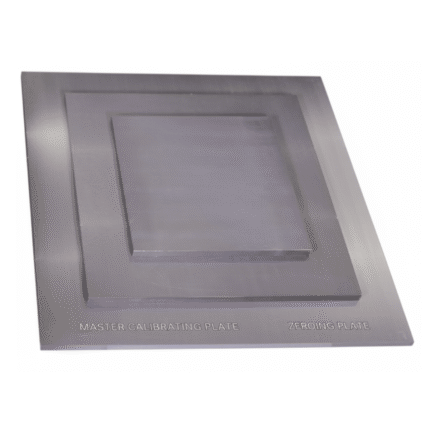

MASTER CALIBRATING PLATE / ZEROING PLATE AZA1270

AZA LAB's Master Calibrating Plate—also known as a Zeroing Plate—is a precision-engineered aluminum reference plate designed for accurate calibration of Universal Gauges and Plucometers. Manufactured in compliance with IS 13630 (Part-1) and EN ISO 10545 (Part-2) standards, it ensures reliable and repeatable zero-point reference during dimensional testing of ceramic tiles and similar materials.

The plate is available in a wide range of sizes to suit various laboratory and industrial applications. With a flatness accuracy of ±0.1 mm and a sturdy 12 mm thickness, it provides a stable and durable base for equipment calibration.

Whether in QC labs or production floors, the AZA LAB Zeroing Plate is an essential tool for maintaining measurement consistency and ensuring compliance with international tile testing standards.

Test Specimen Holder for Surface Abrasion Machine – For Glazed Tiles AZA1264

The AZA1264 Test Specimen Holder is a precision-engineered accessory designed specifically for surface abrasion testing of glazed ceramic tiles in accordance with BIS 13630 (Part-11) and EN ISO 10545-7. It ensures secure positioning of the test specimen and consistent containment of abrasive materials during the abrasion resistance test, contributing to accurate, repeatable, and standard-compliant results.

This holder is an essential component in ceramic tile testing laboratories, quality control departments, certification agencies, and research institutions, where standardized abrasion testing is mandatory for product validation and compliance.

Test Specimen Holder for Surface Abrasion Machine – For Glazed Tiles AZA1264A

The AZA1264A Test Specimen Holder is a precision-engineered laboratory accessory designed for surface abrasion resistance testing of glazed ceramic tiles in strict accordance with BIS 13630 (Part-11) and EN ISO 10545-7. It ensures stable specimen positioning and uniform containment of abrasive loads, which is essential for obtaining accurate, repeatable, and standard-compliant test results.

This holder is widely used in ceramic tile manufacturing laboratories, quality control departments, certification bodies, and research institutions, where conformity to national and international testing standards is mandatory.

UNIVERSAL DIGITAL GAUGE – DIAGONAL LINEARITY PLUCOMETER AZA1272

The AZA LAB Universal Digital Gauge – AZA1272 is a compact and highly accurate plucometer designed for evaluating diagonal linearity and flatness of ceramic tiles. It complies fully with IS 13630 (Part-1) and EN ISO 10545 (Part-2), making it an essential tool in laboratories and tile manufacturing quality control.

Engineered for portability and precision, the device allows fast and direct measurement of dimensional deviations across the diagonal of the tile.

AVAILABLE PLUCOMETER SIZES

-

450 × 450 mm

-

600 × 600 mm

APPLICATIONS

-

Measurement of diagonal linearity

-

Evaluation of tile flatness

-

In-process and final quality control in ceramic tile production

-

Conformance testing as per national and international standards

Rock

Rock Aggregate

Aggregate Cement

Cement Concrete

Concrete Soil

Soil Steel

Steel Bitumen/Asphalt

Bitumen/Asphalt Security Survey Equipment

Security Survey Equipment General Items

General Items